This article will be useful to all woodworking craftsmen. There is such a universal tool called a brace.

In it, YouTube author "George Kosilov" will show you the process of creating this tool for working with wood. Moreover, this is a very easy homemade, performed in 15-20 minutes.

Materials

- A piece of strip from the torsion bar suspension

- A pair of screws

- Wooden block 25X25 mm or two handles from chisels

- Paint for wood or impregnation

- Two-component epoxy resin.

Instruments, used by the author.

- Welding machine

- Grinder, cutting-off and petal stripping discs

- Screwdriver

- Hacksaw

- Ruler, marker

- Vise.

Manufacturing process.

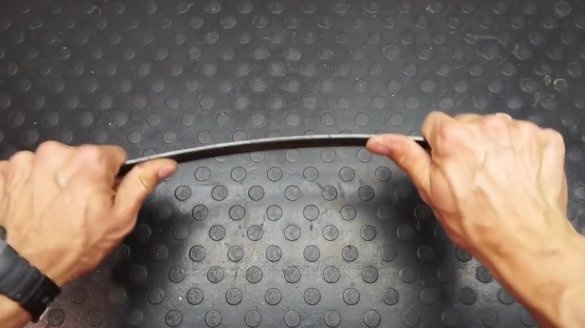

So, the author took a piece of strip from the torsion bar, he will use it as a blade. It bends very well, while the steel is well suited for various blades.

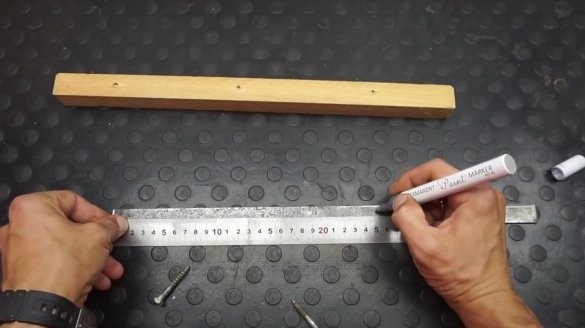

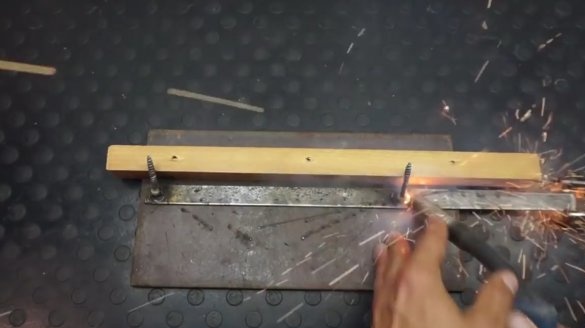

Marks on a strip of 25 centimeters, and puts down screws.

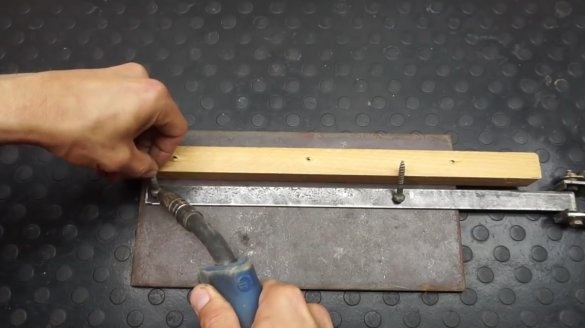

Self-tapping screws must be welded at an angle of about 40-45 degrees.

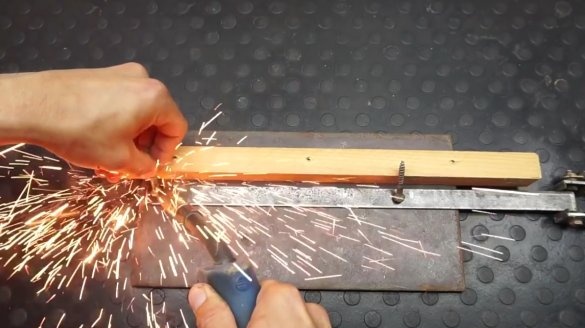

Then, holding the blade blank in a vise, cuts off the excess. Then with the help of a petal disk grinds sharp corners at the edges of the strip.

Now you can sharpen the blade, for this, the author also applies first flap, and then finer-grained discs. Polishing as desired.

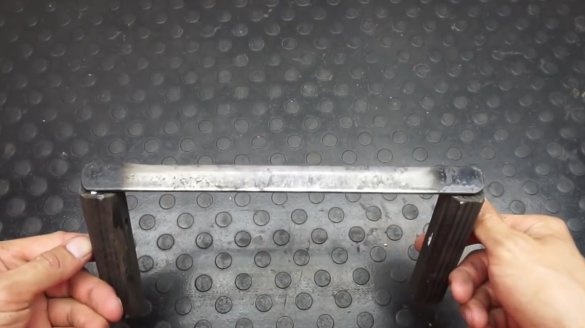

This is what the finished blade looks like.

Further, the author slightly rounded the edges of the block, measures and notes the length of future handles convenient for work.

It fixes in a vice, cuts off the handles with a hacksaw.

Then, fixing them side by side, drills holes for screws.

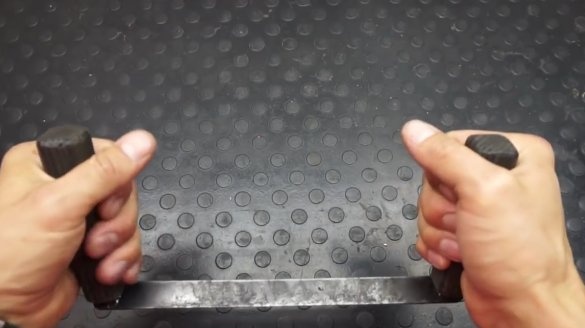

The author impregnated the pens with stain, giving them an almost black color. Screws them on self-tapping screws.

Here is the appearance of the finished tool.

It's time to test the tool at work, check the flaws. It removes the bark very easily, cutting directly with strips.

Knots, of course, are very problematic for a braid.

Here is the result - the log cleared of bark is ready for further processing. The tool did just fine.

After testing, the author identified one flaw, and eliminated it.The handles had to be planted on a two-component epoxy resin, for the reason that they scroll.

That's all, thanks to the author for the recommendations on the manufacture of a simple, but very useful carpentry tool!

Good luck to everyone and good tools!