To make the cider, the master-craftsman needed a press. Having estimated the cost of the finished product, the master decided to make the press himself. For the manufacture of the press you need the following

Tools and materials:

-Gas bottle;

-Threaded rod;

-Profile;

-Fasteners;

-Board;

-Trumpet;

-Metal plate;

-USHM;

-Welding machine;

Cutting machine;

-12 bottles of cola (optional);

-Vise;

-Grinder;

-Drill;

- The coupling connecting with eyes;

-Paint;

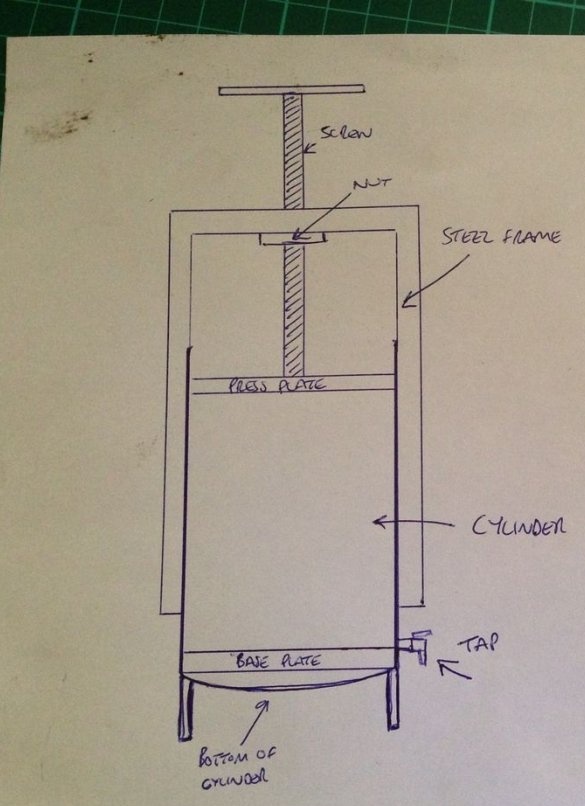

Step One: Design

First, the master drew a sketch of a juicer.

Step two: procurement of parts

Next, the master prepares cuts the pipe plate.

Step Three: Cylinder Cutting

The cylinder must be cut, observing safety measures. Turns off the valve. Fills a cylinder with water. Cuts off the top of the cylinder.

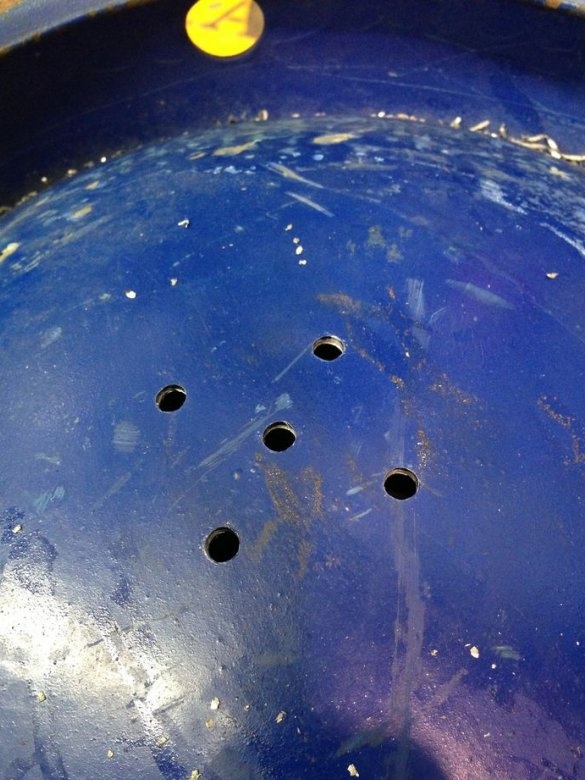

At the bottom of the container, the master drills six holes.

Step Four: Clean the Cylinder

To clean the inside of the container, the master used an unusual method (given the size of the surface being cleaned). For cleaning, pour cola into the container. After a day, the stake is drained and the container is cleaned with a wire brush and water.

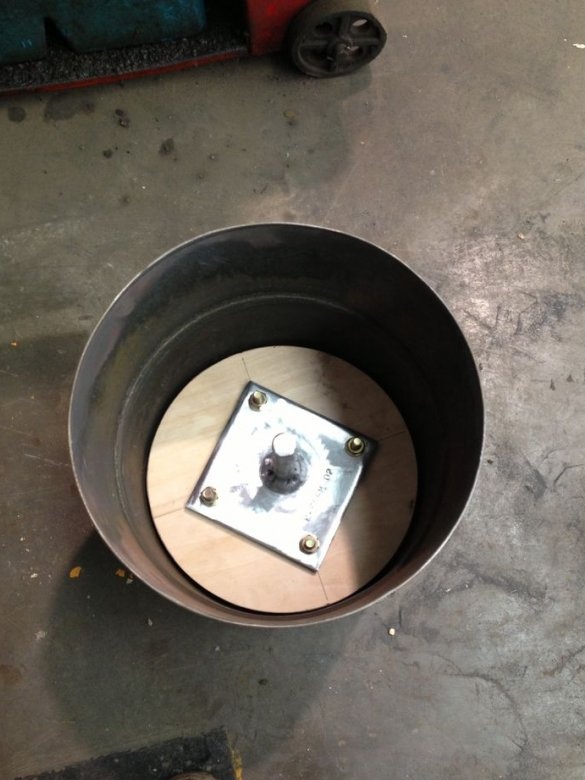

The master made a piston from two 18 mm circles of plywood glued together. A metal plate with a welded rod is screwed to the piston.

Step Five: Making the Rack

Welds press racks.

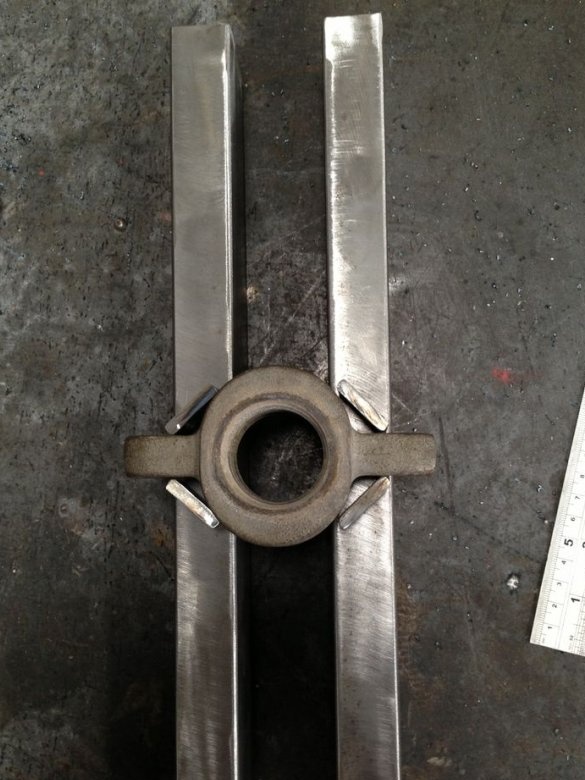

Step Six: Cross

A transverse support is installed at the top of the rack. It is made of two parallel-welded profile pipes. Pipes are welded with plates along the edges. There is free space between the pipes. A coupling is fixed in the center of the cross member. The cross member is fixed with bolts fixed with keys and can be easily removed if necessary.

Seventh step: assembly

Next, the master paints parts of the press. Screws the threaded rod. Secures the piston.

The press is ready.