In this manual, we will look at how do it yourself You can make a very convenient drilling machine. A device based on a 775 engine or the like works. Such motors are now very popular, they are used for manufacturing home machine tools. Motors have high torque, not weak revolutions, and they are also pretty hardy. It is best to choose ball-bearing motors; they serve much longer than the sleeve versions, and you can order them from China.

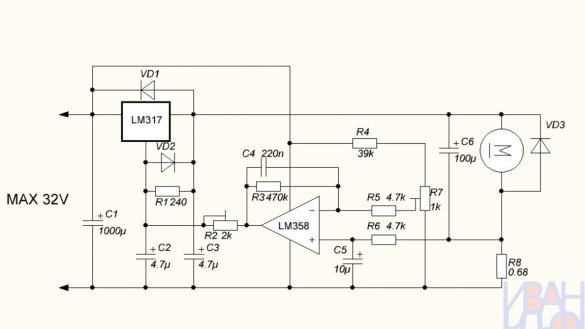

The machine has a speed control function depending on the load on the engine, the author shared a diagram of this device. The bottom line is that when idling, the device shaft rotates at low speeds, but as soon as you start drilling, the speed rises immediately. So, according to the author, the service life of the motor increases, since you do not need to constantly drive it at high speeds. If the project interests you, consider it in more detail!

Distinctive features:

1. Low noise and vibration

2. Illumination of the drilling site

3. The system automatically switches on high revs when the engine is under load.

Materials and tools that the author needed:

Material List:

- or similar;

- ;

-, gear and other parts from the printer;

- power supply 24V;

- wires;

- switch;

- plywood;

- self-tapping screws;

- corners;

- bolts, nuts, etc .;

- threaded rod;

- springs;

- furniture sliders;

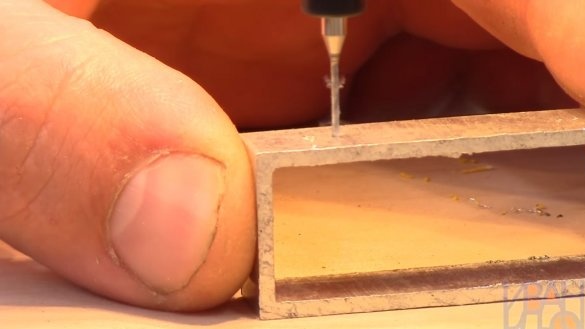

- rectangular aluminum profile.

Tool List:

- drill;

- grinder;

- screwdriver;

- soldering iron;

- a jigsaw or other tool for cutting wood.

The manufacturing process of the drilling machine:

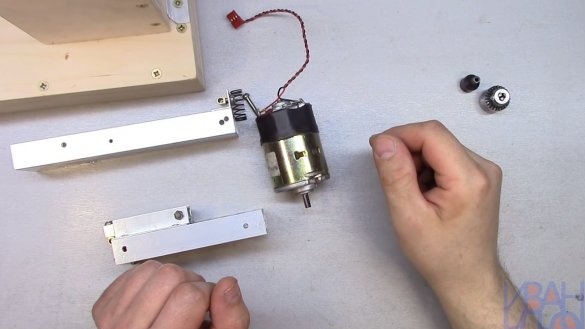

Step one. A few words about the engine

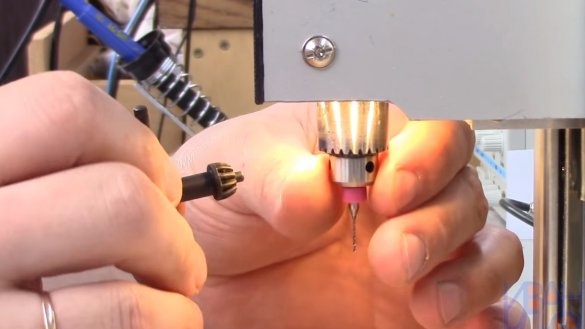

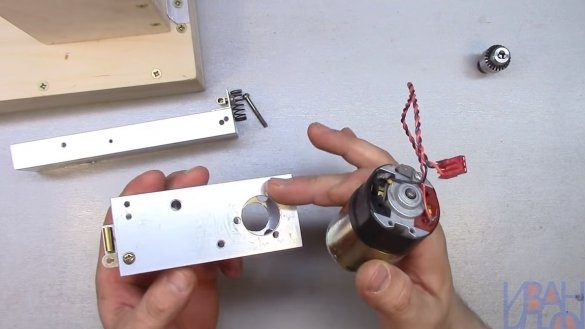

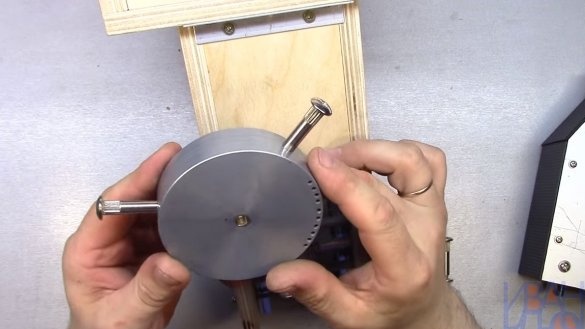

The engine can be used 775, the author used a similar one. The drill chuck is mounted directly on the motor shaft. If the diameters for mounting do not match, you will need an appropriate adapter.

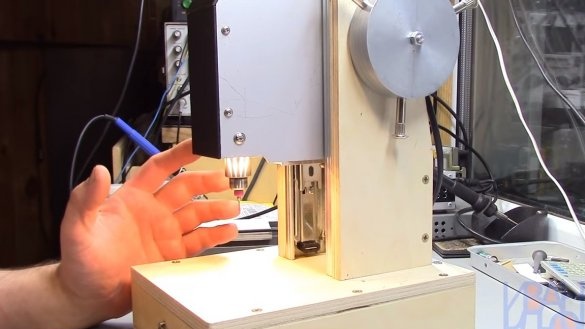

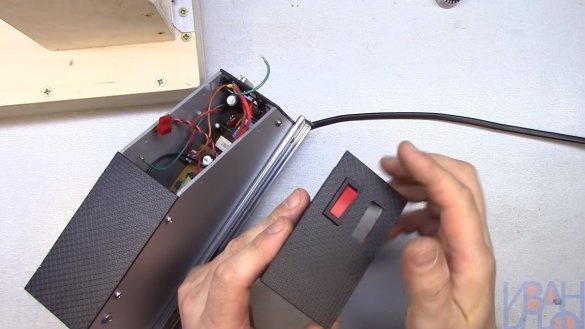

Step Two Housing

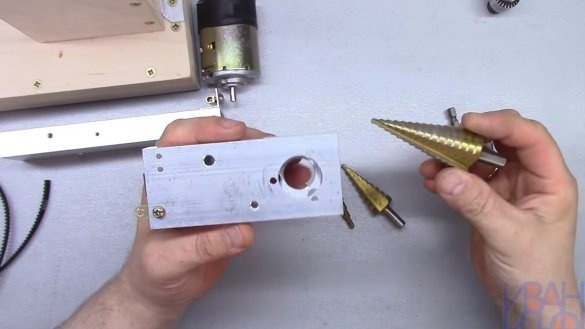

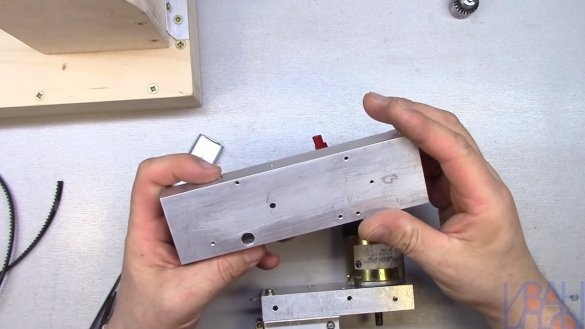

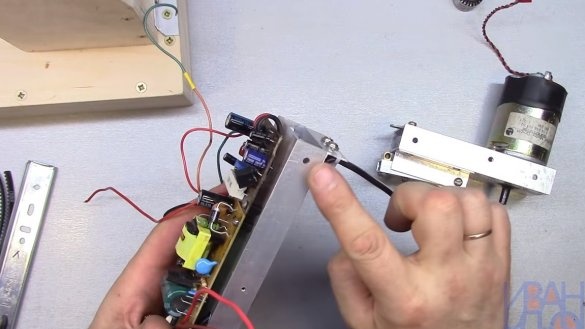

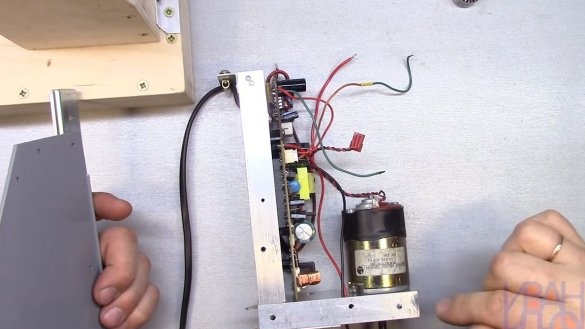

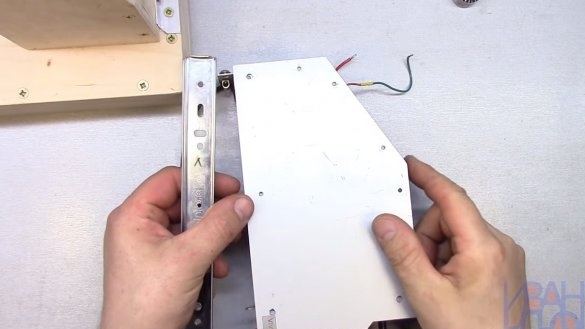

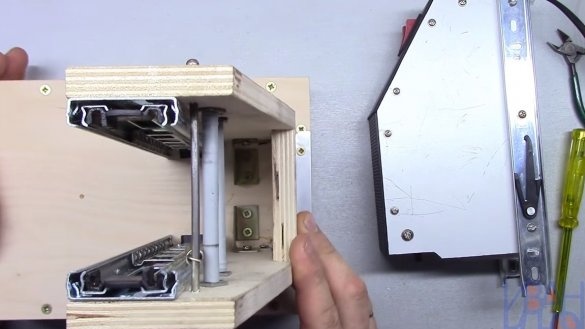

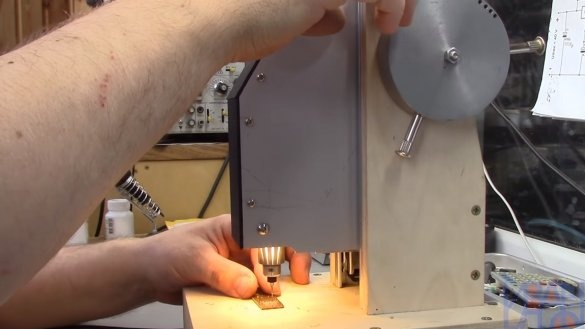

The power supply and engine are installed in a special case, this entire structure will be movable, it rides sliders up and down.The case itself is made of aluminum profiles, and plywood or fiberboard can be used as cladding.

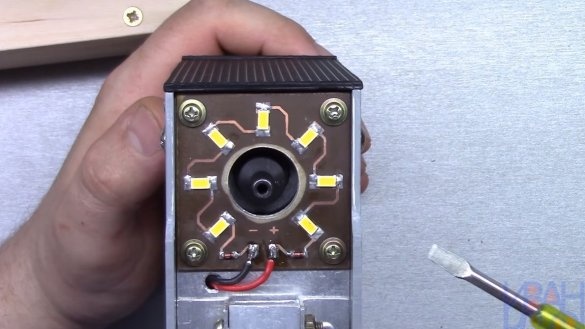

There is also a backlight, the author mounted it around the drill chuck. SMD LEDs were used here.

The tensioner, which is needed to tighten the belt, is also fixed on the profile.

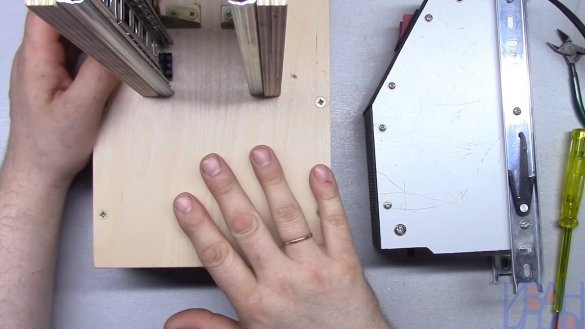

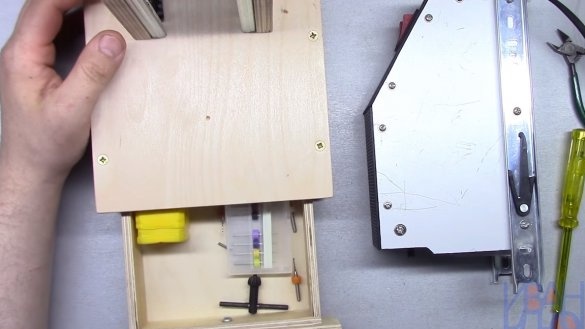

Step Three Base and Racks

The author made the basis of plywood, it is fast, simple and reliable. At the heart of the author there is a pull-out shelf where you can store drills and other tools. The racks are also made of plywood, they are screwed to the base with the help of corners and screws.

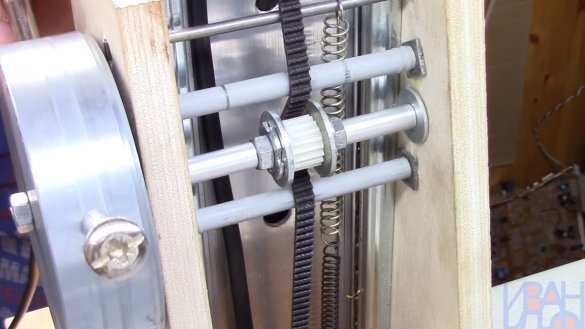

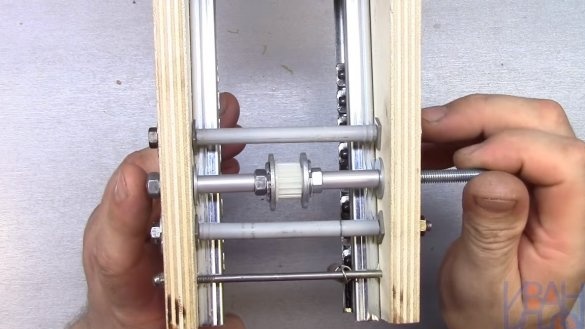

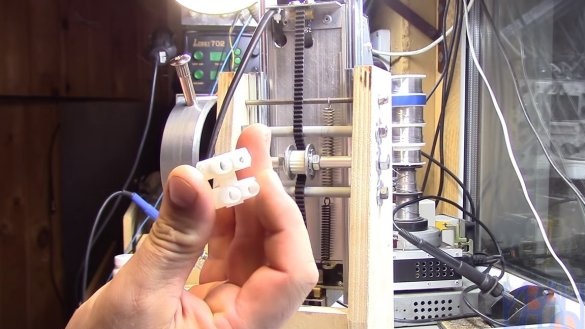

Between racks two axes are installed, on which plastic tubes are put on, they connect racks, and also are guides for a belt.

Step Four Lifting unit

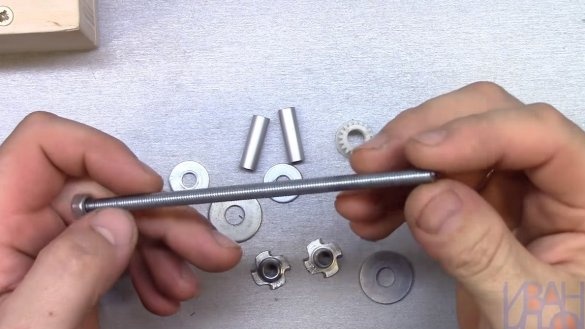

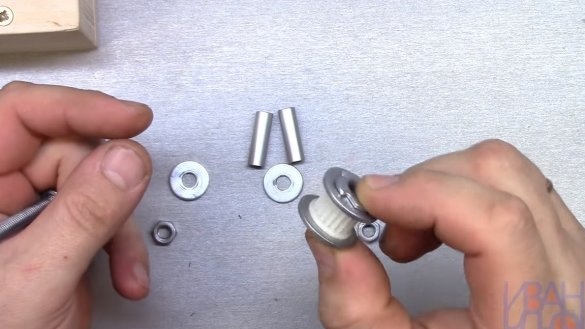

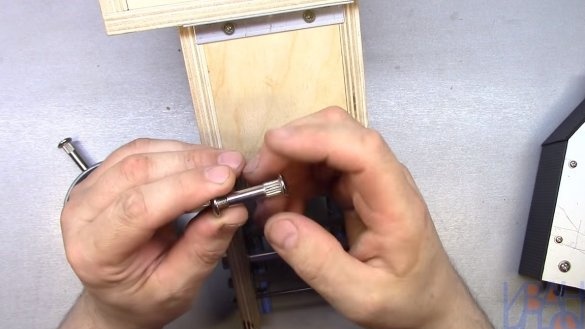

The machine controls the handle that the author made of the part from a cassette recorder and furniture screws. A threaded rod is attached to the handle, on which the gear from the printer is mounted.

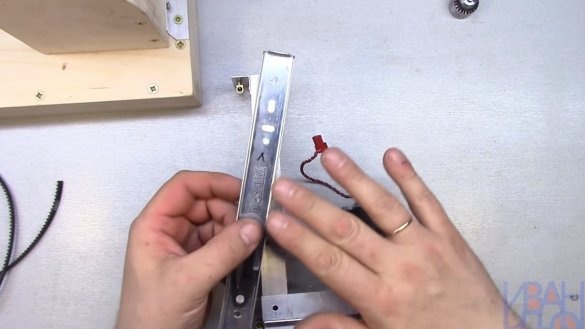

The mobile unit is mounted on two furniture ball sliders, they are quite reliable and almost have no backlash. The belt is fastened with clamping connections for wiring. There are also springs that return the drill chuck to its original state when the handle is released.

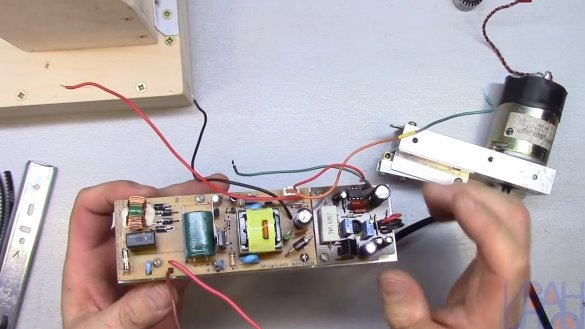

Step Five Electronics

The author installed electronics on the machine, which automatically increases engine speed when the engine is under load. As soon as you lean against the part with a drill and start drilling, the machine increases speed. This is very convenient, and the engine lasts much longer than if it constantly worked at high speeds. The author shared a diagram of his device.

Test

The author demonstrates the operation of his device on video. Drills the machine perfectly, and not only wood, but also metal. The motor power is quite enough, and the device works quietly and consumes little current. I hope you enjoyed the project, good luck and creative inspiration, if you decide to repeat this!