In this article, the YouTube author of George Kosilov tells you how he made a lightweight folding bow and redid the arrows.

Materials

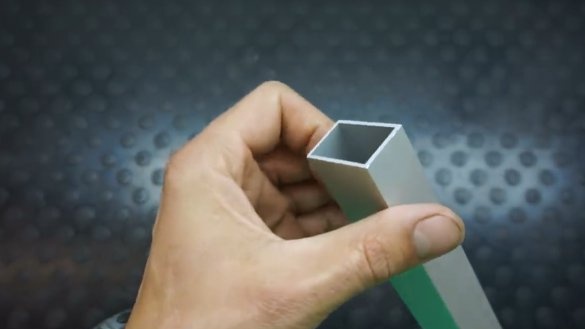

- Aluminum profile 20X30 mm, wall thickness 1.5 mm

- Torsion from the Cossack

- Cut steel profile pipe

- Polypropylene braided cord with a diameter of 2 mm

- Heat-shrink tubing

- Bolts, nuts, washers

- Steel tube with an external diameter of 8 mm.

Instruments, used by the author.

- Welding machine

- Bulgarian with a cutting disc

- Petal stripping disc

- Vise, hammer

- Screwdriver

- Hacksaw

- scissors

- Technical hair dryer

- pliers

- Step drill

- tap

- Caliper.

Manufacturing process.

To begin with, the author cuts off a part of a length of 500 mm from the profile pipe for the future frame.

Next, you need to make a pair of brackets, for this, the author has made and tried on a profile pipe here is such a template from cardboard.

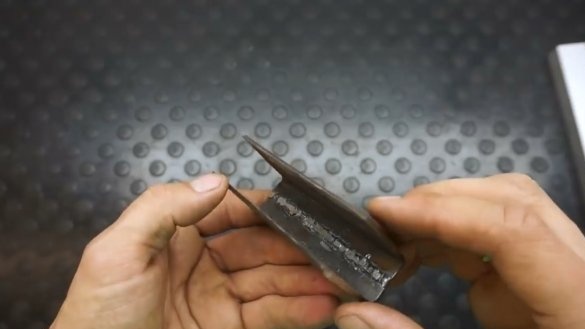

Since no suitable steel pipe was found, the author cuts out the necessary parts using a grinder.

From the obtained L-shaped parts collects a blank for the bracket, clamping them on a profile trim in a vice, boils.

After stripping the weld with a flap disc, a suitable U-shaped workpiece is obtained

A few more improvements to the grinder, and the author got an eye in the workpiece.

Now, holding the workpiece in a vice, processes sharp edges with a file.

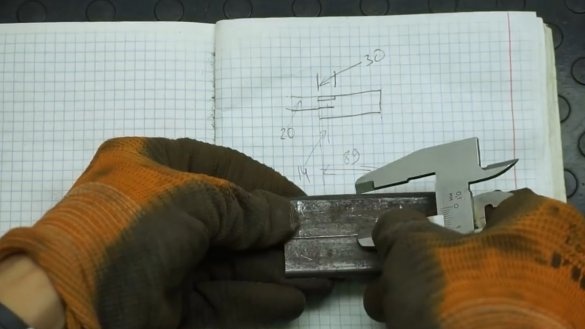

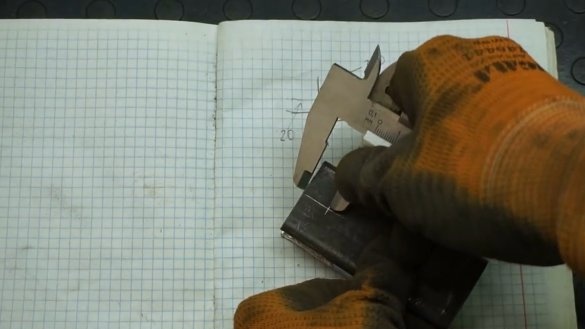

An important point is that it measures 20 mm from the top, and 14 mm from the end, these will be the centers of the holes for the mounting bolts. Then, with the puck in place, marks the ears.

Having cut off the excess, and having processed the workpiece, the author proceeds to fasten the resulting part to the frame.

Putting the frame and the workpiece “under the ruler”, and fixing both parts with pliers, the author proceeds to drill holes for the bolts. Using a step drill, the diameter is adjusted to 8 mm.

Since the frame is aluminum, the author decided to make a sleeve from a piece of steel pipe. It cuts the thread for the bolts with a tap, and cuts the sleeve along the width of the profile, 20 mm.

The sleeve is ready, sits in its place very tightly, I had to "help" with a hammer. Everything, you can mount the holders.

The main part of the frame is ready, everything develops as it was intended.

Trying on torsion bars to the holders, they are great in size, since the strip width is 19 mm.

True, I had to make a lining from the scraps of the torsion bar so that the strip was securely bolted. And drills the bolt holes in the torsion bar.

Attaches the shoulders of the bow to the holders, clamping the bolts with a key.

Since the shoulders were longer than the frame, they will have to be shortened, cutting off the excess with the grinder.

The folding mechanism is ready.

The author tried to pull the bowstring, and when it accidentally unfastened, the bow of the bow folded. Therefore, it is necessary to make a locking mechanism for the shoulders. At first there was such an idea, and many different ones, but they all turned out to be too complicated and uncomfortable.

Therefore, it was decided to make such an ordinary hook. He perfectly holds his shoulders in an open position, and there is no load on him.

An arrow holder was also purchased.

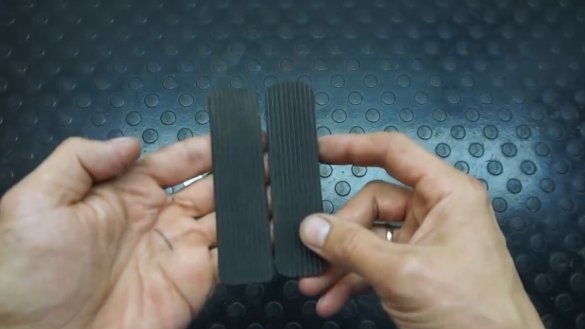

And pens are made of a piece of an old rubber mat.

Having chosen the optimal location of the boom holder, sticks it and gum on super-glue.

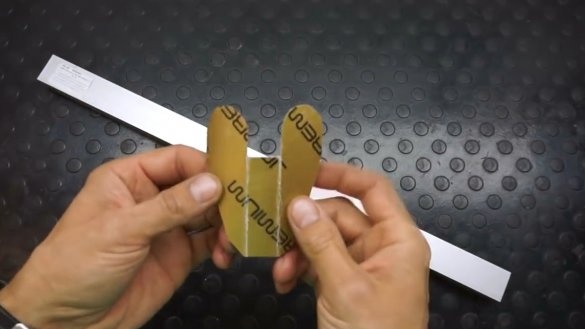

The bow itself is ready, but an important detail remains - the bowstring. For her, a woven polypropylene cord was purchased, only without an internal insert, just like a tube.

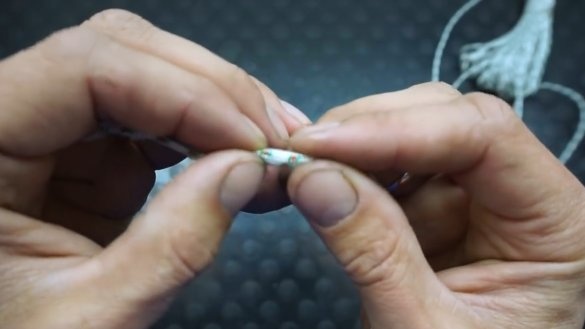

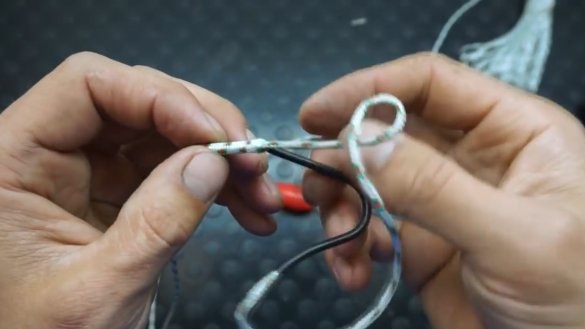

A piece of toothpick is inserted into the edge of the cord and fused with a lighter. It turns out a comfortable and hard tip.

Then he puts on a section of the heat-shrink tube and heats it with a technical hairdryer, the lighter cannot be used. While the tube is hot, it gives it a U-shape.

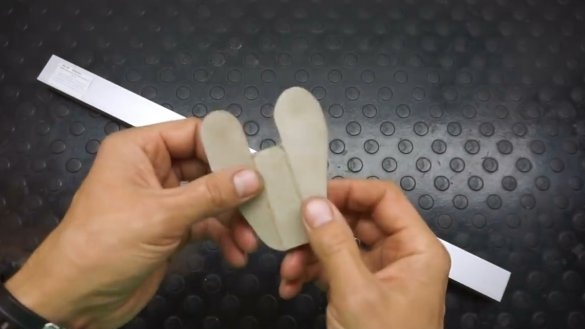

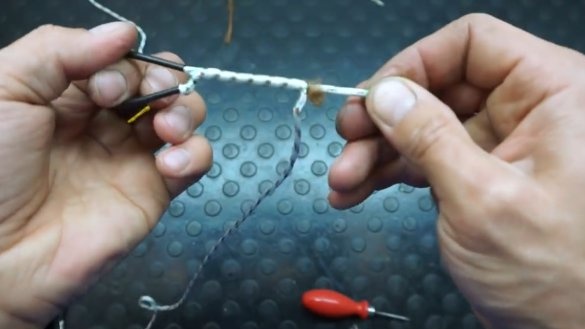

Spreading the fibers a little, pulls the tip of the cord inward, and displays it a few centimeters below. Tightening the tip of the cord to tighten the shrink loop.

Now it simply smoothes the outer layer of the cord, and cutting off the excess, hides the end of the lace inward, smoothes the fibers. This knot holds firmly enough, and does not untie.

Here is such an aesthetic bowstring.

The author did not plan to make arrows on his own, but simply bought them on the Internet. They have a length of 30 inches, they had to take 28. There are spare parts for them.

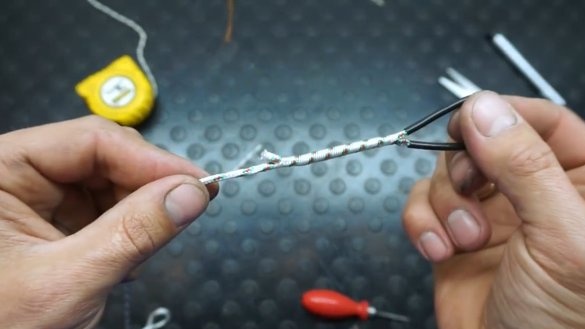

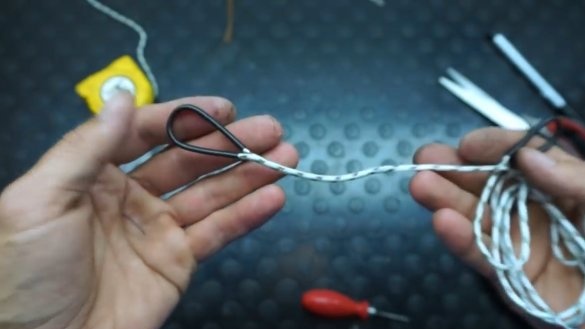

But the problem is that the arrow is longer than the folding bow. The author decided to make the arrows collapsible. Cuts arrows in the middle.

And to connect the boom body to the "working position" will use one of the sections of the old fishing rod.

Having marked, cut and polished several "sticks", glues them to the middle of the length on super-glue in one half of the arrow. After the glue dries, the arrow gathers like this.

So, the bow and arrows are ready, even interesting to weigh them. Almost 800 grams.

Before testing, the author decided to check the quality of the torsion bars by rigidly bending them with a pipe. But even with such mockery, the strip did not burst, although quite fragile.

What effort does a fully stretched bowstring give? By measuring with ordinary weights, the author received about 11 Kg.

Some tests. Gathering the bow and shooting at the target, no complaints about the bow were found.

Here are all the important elements and nodes in sunlight.

Thanks to the author for an interesting project and its implementation!

Good mood to you all!