Mistake No. 1: Jamming of the circular saw blade.

What is going wrong? The author clamped the saw, because the edges of the board fell on both sides, and a compression appeared in the place of the cut. If, when the motor is on, you hear a similar sound, sharp, screeching, then you should immediately turn off the power, because at that moment the motor breaks itself! In this case, everything should be dispensed with. But, perhaps, you will feel a slight smell of rubber from the friction of the belt against the pulley.

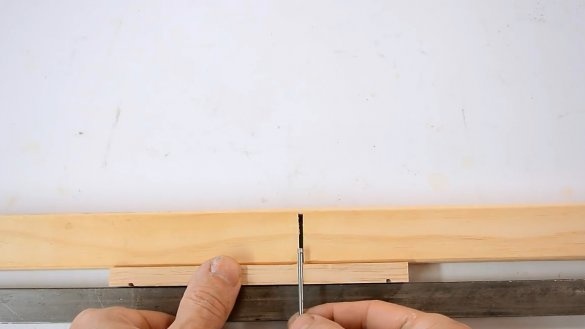

What really happened? When the apprentice made a cut, the blade went deeper and deeper until a thin strip of wood remained.

And this section turned out to be too flexible, while the wood on both sides of the cut is very heavy and rests only on the table slide. The cut workpiece sagged on both sides and jammed the disc.

Such a jam of the disc is observed much more often when using a hand-held circular saw, when you cut a tree that does not rest on anything in the area where the saw passes, that is, if you cut it by weight.

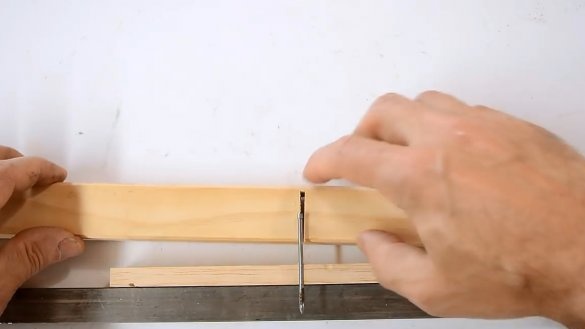

Here is an attempt to cut the beam. The disc did not manage to jam, but a piece of wood blank flew away at a good speed.

And at the same moment, the saw is already moving towards the legs ... Of course, there is protection on the saw, but this is extremely wrong. As they say, they did not drink the branch on which you sit.

Things are worse with the board. The disk successfully jams several times, the tool itself pulls very hard.

Such inconvenience can easily be avoided by laying supports under the part of the tree where the saw blade should pass. In the case of a hand saw, it is enough to find one fulcrum, for example, pressing one end of the tree to the table, and leaving the other end free. During sawing, it will simply fall away.

Error No. 2:

What causes a similar burning of the edges of the part? Are we going through the workpiece too fast or, on the contrary, too slow?

The answer is too slow. When you cut a rectangular panel, most people, knowing that the blade is dangerous, try to push through the wood, staying as far away from the blade as possible. This spoils everything.Imagine, you are making a cut and, instead of touching only the top of the stationary disk (if you push the tree while holding near the stop), you are pressing here and not pressing enough with the edge, giving the tree a rotational moment, thereby pressing the blade of the disk all over the plane. So there is additional friction, causing heating of the wood.

Further, when you finish the cut, if you continue to push the workpiece near the stop, and it is not enough to press here, near the disk, the rotation arising due to this incorrect movement will tend to raise the finish area of the cut.

But the further development of events for a beginner will be completely unexpected. In this case, the blade of the disk is strongly jammed and raises the workpiece. With a huge speed of rotation of the disk, this happens in a split second! And now the wooden panel is already at the top of the blade, and the teeth pull the wood back, which happens very quickly!

Once, and a piece of wood flies right at you, leaving bruises on your stomach, if you're lucky.

Here is the correct clamping of the sawn plywood sheet at different stages.

As for the firing of the cut, the lateral pressure on the disk, a blunt blade or hardwood reinforce this effect. Similar tanning marks may also appear as a result of cutting too slowly.

Now the author will try to make a cut in this piece of wood. At the same time, almost two horsepower is supplied to the saw, so that he will not be able to cut the bar quickly enough. So, this opinion was erroneous. The author was sure that there would be traces of fire, but ... no! They are not visible. Perhaps this is a good drive.

However, the author clarifies that if he had to cut the solid rock of the tree to the same depth, he would still do it in two approaches. Even if he had to make two cuts and raise a blade between them, the total time spent on this process would ultimately be less.

So, the first pass, at half the thickness of the workpiece.

Now the second pass, the master raises the blade to the full height.

Before you are two made samples. Here is the previous one. If you look closely at him, you will notice slight stains and subtle signs of burning.

Thanks to the author for the master class, perhaps this article will save someone from a mistake.

Be careful when working with machines, observe safety precautions!

Be sure to use protective fixtures!

Be sure to use protective fixtures!

Good luck to everyone, and safe work with tools!