However, there are some useful and simple tips that will help in this process right now. For their implementation in practice, you do not need to have special skills or have expensive equipment, and they will practically not take time. However, their use can improve the quality of work with wooden parts.

Tip 1. How to get rid of chips when cutting plywood with a jigsaw

When working with plywood, beginners often have a problem with chips: a jigsaw, sawing a part, splits a part of the upper and lower layers on both sides of the cut.

Of course, with experience, the perfect cut will be obtained without any tricks - you just need to choose the optimal file, choose the right speed and tilt of the tool. However, this comes with experience. If it is still not enough, but you want to achieve an acceptable result, you can use the following advice.

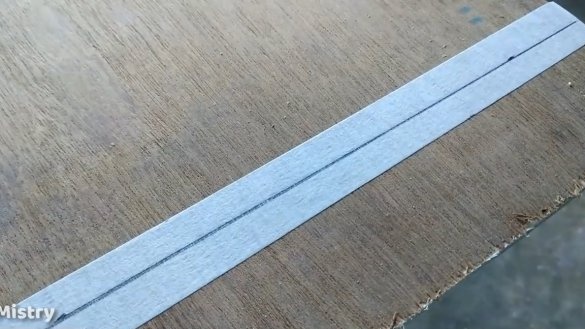

It is necessary to mark the workpiece and stick on the cut line a strip of masking tape.

Before cutting the plywood, we again draw a marking line on the masking tape. After this, we proceed to sawing the workpiece.

At the end of the process, you will see that the result has become much better, since adhesive tape, acting as a protective coating, prevents the splitting of plywood.

This method, of course, is not a universal panacea. A certain number of chips will still be formed. However, they will still become much smaller, and the amount of splitting will not be so large.

Thus, the quality of cut will improve significantly.

Tip 2. How to quickly remove excess glue from hard to reach places

Bonding of wooden parts and their subsequent compression inevitably leads to the fact that excess glue is forced out.

If the glue hardens, removing it will not be so easy, so it’s better to get rid of it right away. And if from the outside it is not a special problem to assemble it, then some difficulties may arise at the internal joints with this. After all, if you clean it with a rag, that is, there is a risk of moving the just glued parts.

So that in the process of removing excess glue, do not touch or press on the place of their connection, you can use an ordinary straw for drinks.She's great for this purpose. You need to slightly crush the lower part of one of its ends - to get a groove that will follow the contours of the corner - and then simply draw it along the junction of the two parts, where excess glue has come out.

The straw will collect glue in a hard-to-reach place - the inner joint. The remaining surpluses can be easily removed, no longer afraid to move the glued parts.

Tip 3. How to quickly mark a long workpiece

When processing long wooden workpieces, beginners face difficulties with marking. Especially if only a short ruler is available. When, for example, you want to cut a few centimeters from such a long part or mark the workpiece in several parallel lines, you need to spend a lot of time to accurately and correctly measure and draw the cut line.

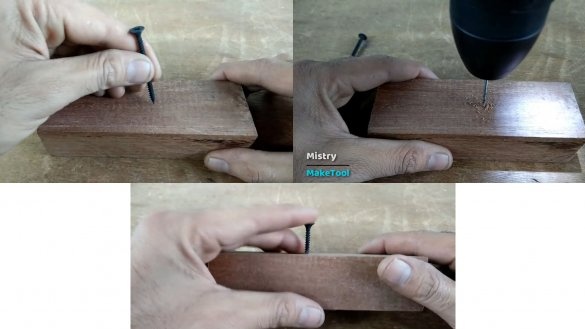

Here is a way to do this operation faster. For its implementation, we need a wooden block, a screw and a drill.

Approximately in the center of our block we drill a hole and screw in a screw.

Then in several places we mark the workpiece by measuring the desired distance along the ruler. Now you need to set the same values on our device for quick marking. To do this, we attach a ruler to the screw and turn it (or vice versa, twist it) until the head in height matches the desired division on the ruler.

After that, we turn the bar sideways and apply it to our workpiece so that the screw head rests on its surface, coinciding with the mark. If necessary, additionally adjust the screw by screwing it in or out of the bar.

And now, making reciprocating movements, we drive a block with a screw along our part. The head of the screw makes a smooth and noticeable groove in the tree, along which it will subsequently be possible to cut the workpiece.

If you want to draw another line, again make a mark on the workpiece and set the screw at the desired height, after which we mark out.

We hope that with our advice the quality of your work will improve, and the process itself will become simpler and easier. Good luck in the manufacture of wooden products!