In this article, the author of YouTube channel "John Zhu" will tell you how to make a stylish Japanese hammer "Justin Hammer" from steel 10/18. At first, the master had some doubts as to whether the material would turn out to be too soft for its purpose.

However, he took a risk and made a hammer. The weight of the hammer head is 270 grams. After several weeks of testing, the tool has proven itself remarkably. The author had to debug his planer, redo it a little. And John used his new hammer, instead of a wooden hammer, gluing a piece of thick leather to one side of his head.

Materials

- Round steel diameter 1 inch, steel 10/18

- Oak bar

- PVA glue

- Beeswax

- Flaxseed oil.

Instruments, used by the author.

- Miter saw

- Bulgarian

- Vise

- Marking planer

- Chinese saw

- Drilling machine

- Engraving machine

- Technical hair dryer

- File

- Chisels.

Manufacturing process.

So, the author will show you how to make such a hammer yourself without using forging. Before you is a steel bar 10/18, with a diameter of 1 inch, and weighing approximately 100 grams per inch of length. John cuts a piece of the required length with a miter saw.

Then marks the center line with a cutting disc. Then he smooths the tip a little to make the drilling process a little easier.

Steel 10/18 is quite easy to drill. True, it is important not to forget to use more lubricating coolant and try to drill very slowly.

Thus, he drills three adjacent holes, which are practically superimposed on each other. These holes were even better than expected.

Then the master removes sharp edges from the inside using an engraving machine. By the time the cleaning work was completed, only a small tubercle of half a millimeter remained from the grooves.

Modifies the inner surface with a file.

For the hilt of the hammer, the author uses a piece of oak wood, which has remained with him since he finished work on the workbench. Applies the required dimensions with a marking surface gage.

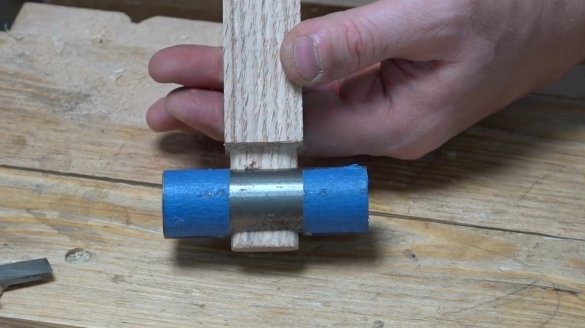

Then the author cuts a spike for mounting the hammer head. And here is the moment: this spike should be rounded so that it is put on the head.

Finishes the tenon processing with a file.

Now, when the handle and the head of the hammer come together, the master cleans the steel, making one end of the hammer slightly convex and the other leaving it flat as it is.

John quite liked the shiny appearance of the hammer, but, after a little reflection, he decided to blacken the head.

The easiest way to do this is to throw a knob at the stake. And, after a little time, remove it from there and cool in the water. This procedure of heating and quenching, by simple hardening, should be done several times. The result is a uniformly black surface.

This is how the workpiece looks after hardening, it had to be washed a little.

All that remains to be done is to complete the formation of the handle, and prepare the grooves in the spike for installing two wedges.

Refines the shape of the handle, polishes it with sandpaper.

Installs the handle in the hammer head.

Wedges made of ebony / ebony. Glue is poured into the gaps.

When the glue has dried, the author cuts off the excess material.

He covers the surface of the handle with a layer of linseed oil.

And after absorbing the oil, the beeswax heats with a technical hairdryer, and additionally processes all wooden surfaces.

John got a beautiful tool!

Thanks to John for a detailed description of the manufacturing process of the Japanese hammer!

Good luck to everyone and good mood!