The author of the YouTube channel "John Zhu" is pleased to bring to your attention one rather remarkable little thing - this is a homemade screed made of leather. With the help of such ties, it is extremely convenient to fix the wires, cables, and put things in order near your workplace by arranging the constantly tangled long wires.

Materials

- A piece of thick but supple skin

Instruments, used by the author.

- A set of chisels

- Knife

- Ruler, marker.

Manufacturing process.

So, here is a skin clipping on which the author draws a longitudinal line parallel to this even edge.

He cuts along the contour with a knife, after placing another piece of leather under the back of the ruler so that it does not fall back, and the cut was accurate. This may not be leather, but any other material that is the same thickness as the product: a section of linoleum, thick cardboard or plywood. The main thing is to withstand parallelism, that is, cut an even strip of material.

During the first pass with a knife, only a very light cut should be made, with almost no effort, and when you cut deeper a second time, a ruler is no longer needed.

So, the author makes the second cut by hand, just inserting the knife blade into the formed cut

And now, a strip of leather is ready.

Now, with the help of a chisel, John cuts the uneven edges of the leather strip. He wants the belt to have a pointed shape from this angle.

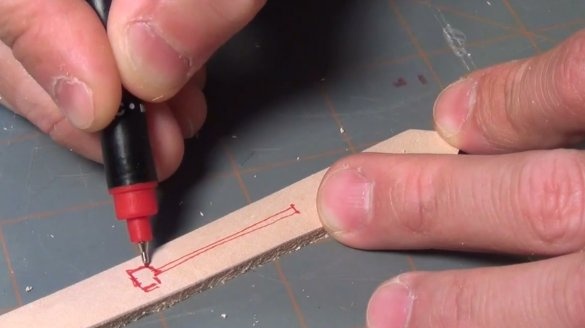

From this angle, he drops about half an inch down and draws two symmetrical squares on both sides.

On the other hand, the master will use a wide chisel, and with her help makes such a marking: a square and two approximately such lines, the diameter of the girth depends on the location of this cut.

First, he cuts out this area, for this he uses a chisel a little more than 1/4 of an inch. Press should be perpendicular down.

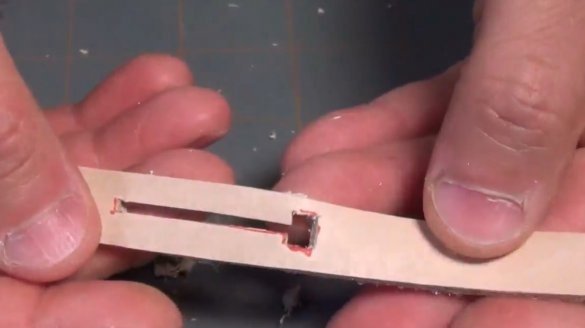

And here John uses a 1/8 inch chisel. One edge of the screed is ready.

Then the author makes a cut in the middle of the strip according to the marking, using flat chisels of various widths.

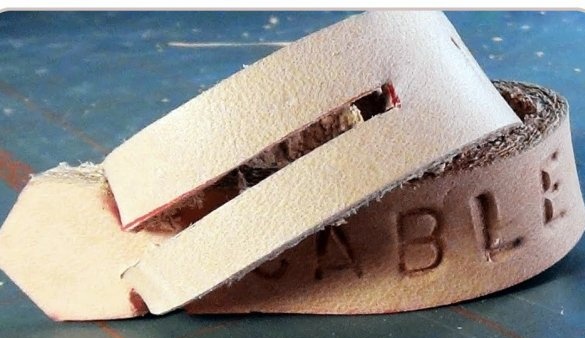

To assemble the cable tie, you just need to stick the strap in the done oblong hole and turn it perpendicularly like this.

Now the screed is securely fixed.

John got a stylish, durable screed. It remains to pierce the logo with a hammer and a set of letter stamps.

Thanks to John for an interesting idea.

Good mood and good luck to everyone!