This article will describe the manufacturing process of a simple rack and pinion jack. Such a jack can lift a car or any other heavy thing. The design is not complicated, all sizes are taken into account the available materials.

Materials and tools used by the author

Material List:

- a piece of channel (200);

- profile pipe (square, 40X20, wall thickness 2 mm);

- steel strip thickness 8 mm;

- bolts, nuts and other little things.

Tool List:

- welding machine;

- grinder;

- a drilling machine or drill;

- spanners.

You will need to trim a two hundredth or larger channel channel length of 60 mm. It is possible to make such a part from a steel strip.

We mark on the shelves of the channel openings 20x40 with an allowance of 2-4 mm for the profile pipe 20x40.

Cut out these holes in any way possible.

If necessary, process with a file.

A profile pipe 20x40 mm should pass freely in them.

We take a piece of a half-inch water pipe with walls of 2-3 mm. Its length should be greater than the width of the part from the channel by 5-6 mm.

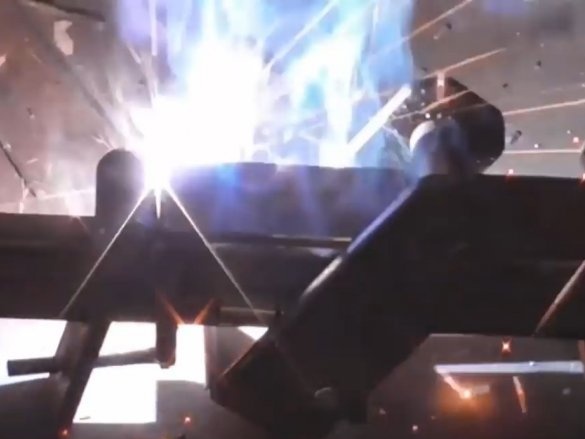

We weld the tube to the channel.

Now you need a strip with a length of 500, a width of 60-70, a thickness of 8-10 mm. Mark the strip - at the edges should be 200 or slightly more, in the middle should remain 65-70 mm.

To bend a strip of this thickness, you need to cut it with a grinder about half the thickness, after which it will easily bend in a vice.

The bent letter P strip along the notches is boiled for strength.

Now this part must be drilled or holes made in another way, for example, burn a hole with a diameter of about 20 mm with a burner.

The holes are ready. Now we can begin to assemble our design. We make the axis from a suitable round to pass into the welded tube, it can also be a stud or a bolt of a suitable size.

We put in place and scald.

That's what we got.

Now, from the same strip with a thickness of 8-10 mm, two clamps need to be made. Mark the holes for the profile pipe and cut it out.

In the U-shaped part we drill a hole with a diameter of 12-14 mm.We insert a bar into these holes and scald.

Also need 4 nuts for 6.

They are needed for attaching the springs. We weld 2 pieces on a clamp and 2 pieces on a channel.

We drill a 10 mm hole in the second fixture and bore it to an oval shape.

We weld a 10-bolt to the channel.

Now it is necessary to make and weld an emphasis for the second clamp.

Here it is made of a piece of thick-walled tube.

The final fitting.

The jack is almost ready.

It remains only to weld the lever to the U-shaped part, and to the channel bracket or shelf for attaching the hook or platform for emphasis when lifting heavy.

That's all. Good luck in your work.