Today, together with the author of the YouTube channel AlexGyver, we’ll try to design and make a mini vacuum cleaner for home workshop.

What is a home workshop? This is when after each sawed-off board or after a drilled hole you have to sweep or vacuum the floor, because otherwise the sawdust will spread throughout the apartment. Each time, getting a huge vacuum cleaner quickly gets boring, and it was decided to make a mini vacuum cleaner with a cyclone filter, which will be powered by a 12 or 24 volt power supply unit to quickly remove garbage from the work area.

Let's start with the motor. The author has long been purchased on aliexpress with 775 screwdrivers. They are inexpensive, very powerful and, unlike brushless ones, do not require a driver and a separate controller for control. So in the name of simplicity and accessibility we use them.

The motor output shaft has a diameter of 5mm, and from the same Chinese you can buy an adapter from the shaft to the M6 thread.

There are 3 types of these motors: 80, 150 and 288W.

Here is a table with their characteristics from the Chinese.

For a vacuum cleaner, we will use a 150-W high-speed motor, since we will need revolutions in the turbine.

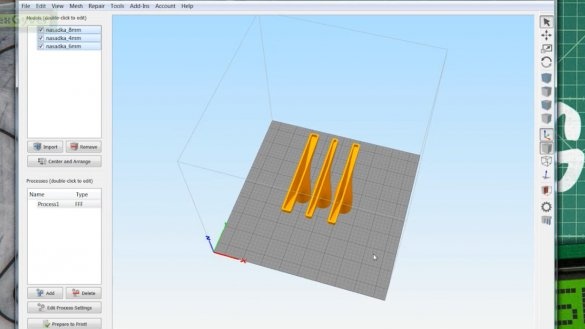

As for the turbine and other components, we will print them on a 3D printer, but we will have to design a little.

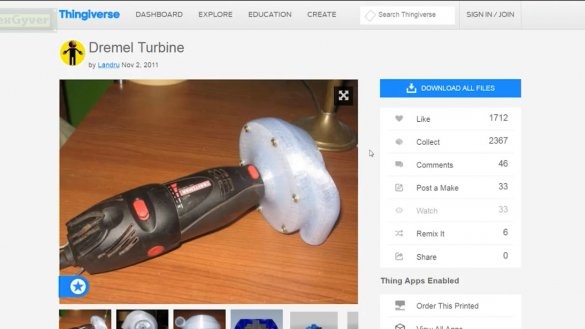

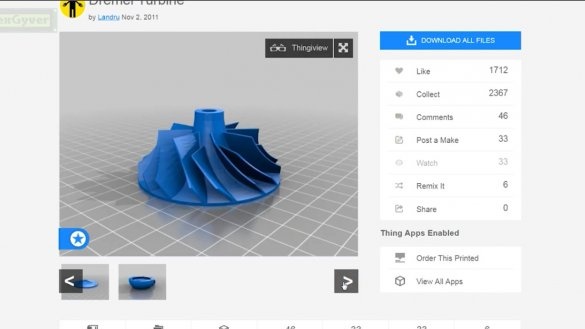

The reference point will be the turbine for Dremel, which is located on the site with 3D models turbine upon request.

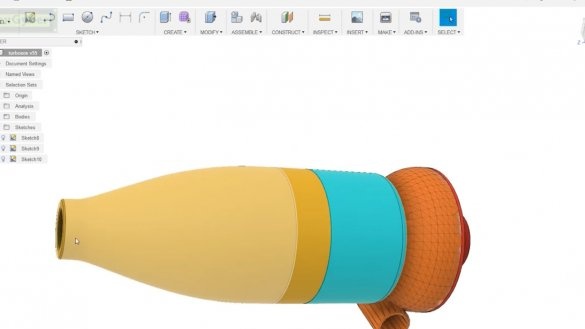

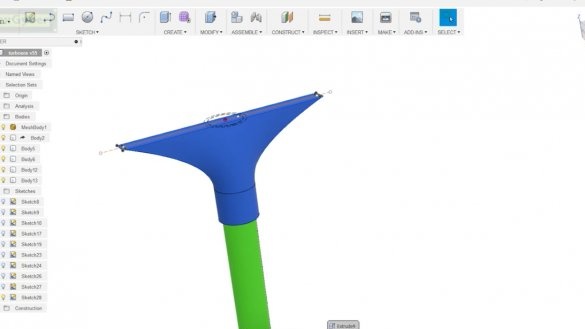

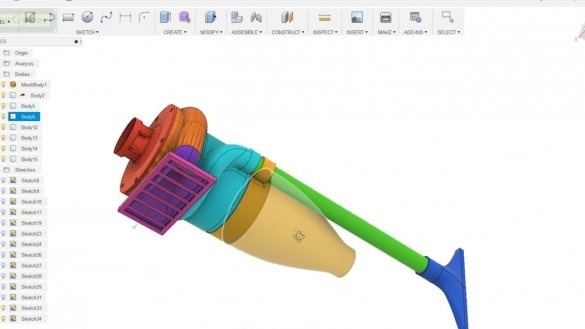

This is a very popular and unprofessional look very competently made model. The best part is that there are source codes in the archive. First we need to fix the 775th motor on the turbine, we will make an adapter, or rather, our own turbine cover.

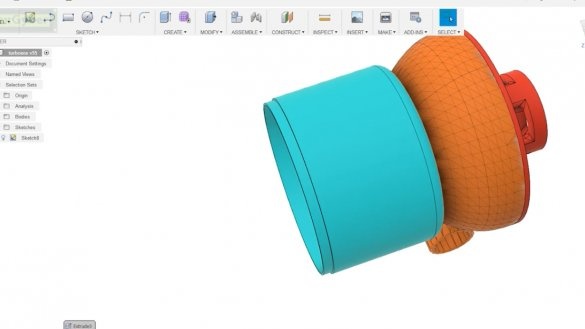

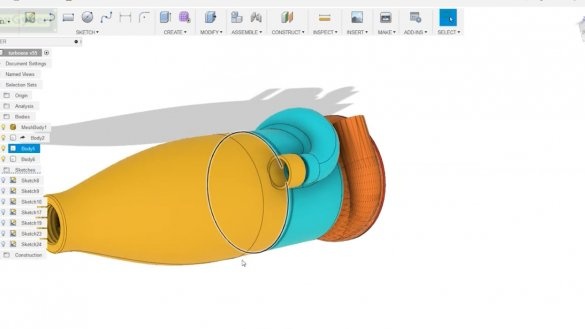

It took about half an hour and 20 operations to build. 3D modeling is not as complicated as it seems, and at times more interesting again than it seems. Let's continue designing the vacuum cleaner. Now we have a turbine with our motor cover, we will make a cyclone filter. In one motion, we rotate and turn the profile into the upper part of the filter, which will be attached to the turbine.

And we’ll do the holes right away.

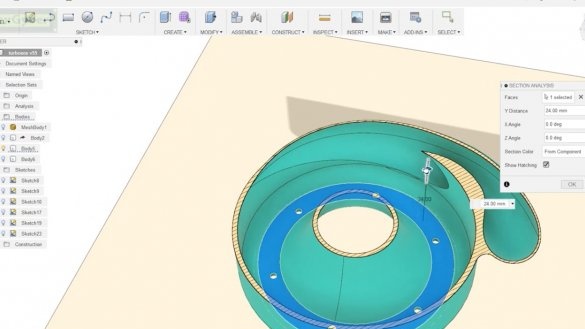

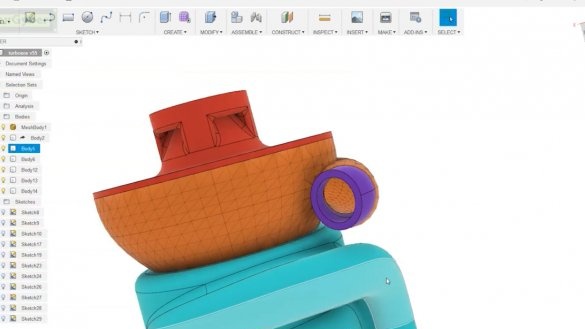

Similarly, we get the bottom of the filter. They, by the way, will be inserted into each other, the author left a step for this.

Next, a difficult moment, we make a three-dimensional sketch of the pipe, which will introduce air into the cyclone. The inner diameter is 20mm, since the pipe of the vacuum cleaner will be a round pipe for laying wires, you most likely have such pipes in the staircase, Internet wires are laid on them.We rotate the cylinder inside and cut off the excess part of the pipe, we get the entrance to the cyclone. The flow inlet must be tangent to the main cyclone tube.

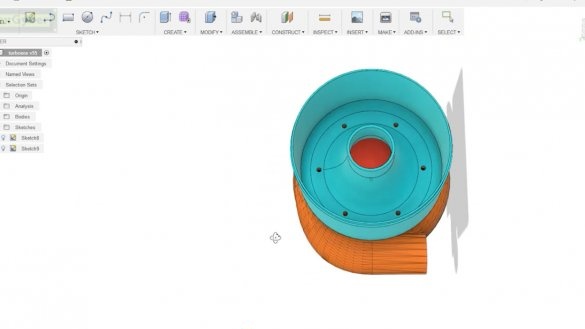

Next, add a fillet to strengthen the design and make printing easier for the printer. After measuring the thread on the bottle, we cut a bottle similar to the bottom of the filter so that you can screw the bottle into it to collect garbage. We will strengthen the fastening of the pipe by adding one more ringlet to the bottom of the cyclone. And again, we round everything.

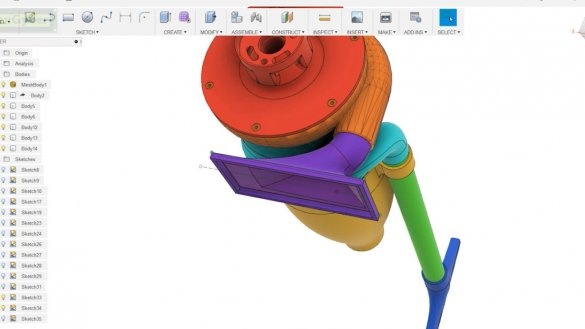

Let's make a nozzle, like a real vacuum cleaner. We cut through. And we make a side.

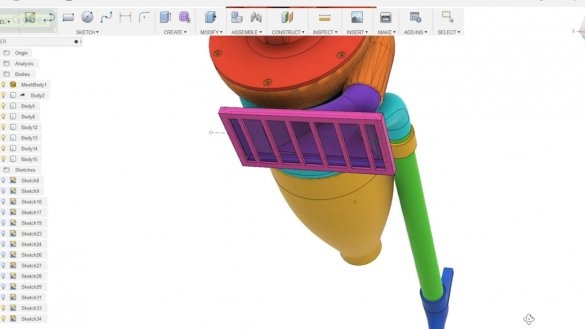

Now we make a filter to exit the turbine, it will be inserted into the outlet pipe. We bend a little way out to bend the air flow. We make a side. And cut through. We pull out the box, it will be the filter cover. A pair of fillets. And add the grill to the lid, inside, of course, there will be foam rubber.

And the last touch - we strengthen the fastening of the pipe. Everything, the vacuum cleaner is ready, it remains to print it.

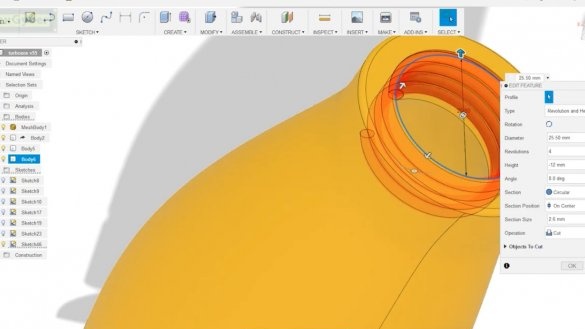

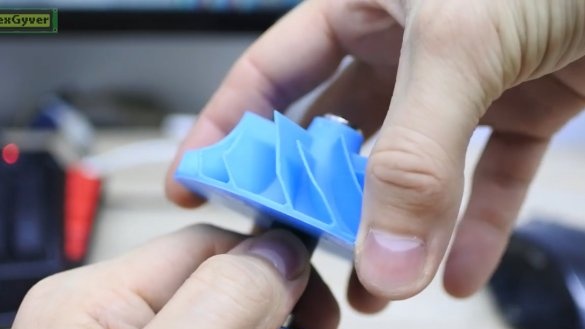

You can download all models for printing and source codes on project page. There are some printing recommendations in the archive. Now look at what the main beauty of this project is, namely, how we will mount the impeller to the motor.

Furniture screed. Large, with M6 thread, is screwed onto the adapter. We insert the screed into the impeller. It should come in tight, but not enough to tear the plastic.

Perfect. Spins, spins, blows. And almost does not hit. There are no vibrations at high speeds, and most importantly, it blows, blows from the heart! We assemble the turbine.

Very good blowing, tight powerful stream. And it seems to suck pretty well. The only thing is that this power supply does not pull the turbine at a voltage above 12 volts, and this is bad. The author planned to fry all 24 there, although the Chinese do not recommend doing so. In general, an 80W motor works. And by the way, it can almost hold a heavy tennis ball.

I decided to power directly from the power supply to 24V, 6A. And the block goes into defense. Well, very obvious.

The third option is a powerful lab technician. He pulled 13B. Well, come up with something.

Although blowing and so very good. Let's try to collect a bottle of cyclone.

Perfect! Between the flanges we will make a gasket of hot-melt adhesive, simply applying it with a thin layer. It will be pressed and tight connection will turn out.

We will do exactly the same when assembling the turbine. The cyclone bottle will need to be assembled onto the rubber glue of the "Moment" type, so that again it is hermetically sealed. Well, there was a pen. By tradition, we use a 50mm sewer fitting, which is remarkably stretched on a motor with several layers of electrical tape. But first you need to solder the wires and the switch.

By the way, the author found the ideal power source for a vacuum cleaner: a 16V lithium battery from a quadrocopter. He is small and damn powerful, such a motor does not care for him.

So we solder the motor output through the switch to the XT60 plug, connect the battery to it and assemble the handle.

And so we got a vacuum cleaner that unexpectedly runs on battery power, at first this was not planned. Let's try it in action!

It sucks perfectly, but there was a problem with the nozzle: the gap is too narrow, and it clogged with fragments from the chipboard. Ordinary sawdust by itself fly by calmly. So in the archive with the models, the author made 3 different nozzles with different bell widths, if someone would make such a vacuum cleaner.

How will he deal with small pebbles?

Yes, just fine, all the pebbles fly in, spin in a cyclone and fall into a bottle. So they collected all the sawdust and pebbles. Even unexpectedly, but it works clearly.

The cats dropped the flower very on time, and a little land remained on the carpet. Let's try to collect!

Great, not only the earth was gathered, but also some kind of dust and hair. This means that the cyclone designed by eye has exceeded all expectations and perfectly collects garbage in a bottle. And let's finally try the nozzle with a wider slot, it just printed.

Gorgeous thing turned out, no comment. Well then, that’s all.Thank you for attention. See you soon!

Video: