Today, almost everyone uses headphones or chargers, the wires of which quite often fail for various reasons. It is unreasonable to buy a new device because of a broken wire, as it can always be repaired, even if there is no soldering iron on hand. Let us consider how this can be done so that the place of repair is not "conspicuous".

In order to repair a broken wire, you will need a sharp knife and a piece of heat shrink tube corresponding to the color and diameter of the wiring. Shrink products are sold and they are quite inexpensive in comparison with the new device.

Repairing a simple two-wire wire is as follows:

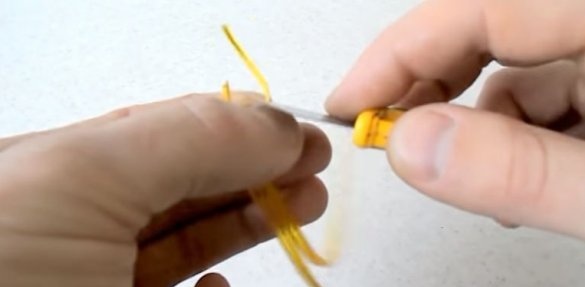

1. Pass one of the ends of the torn wire into a heat shrink tube and advance it further along its length.

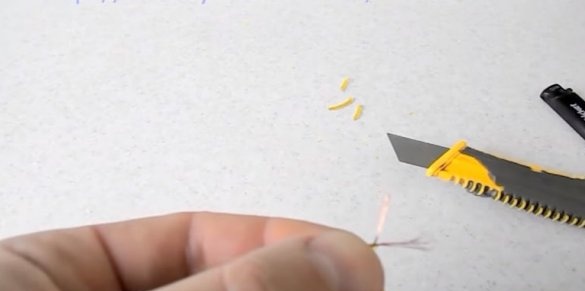

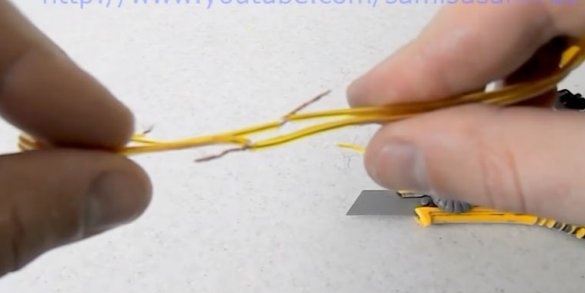

2. Using a knife, cut the insulation between the veins of both ends of the torn wire and spread them apart from each other.

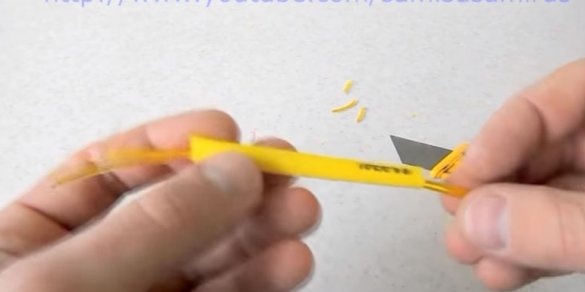

3. At each end of the connected wires, one of the cores is made 1-2cm shorter than the other

and with a knife they clean its tip from isolation. This must be done carefully, holding the blade of the knife at a slight angle to its surface, otherwise it may damage the wiring of the core.

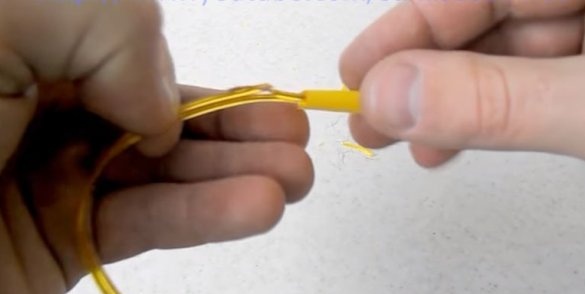

4. The wiring of the connected cores, "fluffing", is divided into approximately equal bundles,

which spread apart from each other.

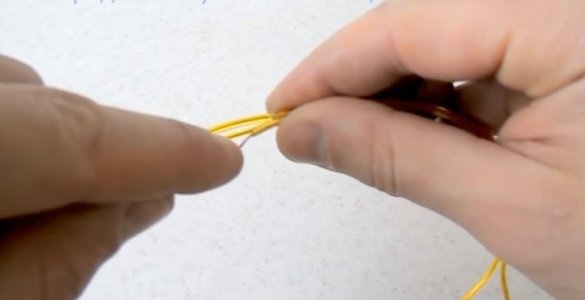

5. Combine the "crosshairs" of the divorced bundles of wires of the connected cores

and fingers neatly and tightly twist them together.

6. The second, unconnected and uncircumcised vein is applied to the connected one, at one of its ends mark a place about a centimeter from the twist made,

and, starting from this place, they remove the insulation from it with a knife.

7. The same amount of insulation is removed from the second end of the unconnected core.

Too long wiring conductors cut off, the length of the "tails" for twisting should not exceed about 1.5 cm.

8. Connect the second core of the wire in the same way as the first, dividing the wiring of its ends into bundles and twisting them tightly.

9. Lay the "pigtails" twist the wires along the wire in the opposite direction to each other. As a result of twisting the cores, a decent distance is excluded on the wire, eliminating contact between them.

10. Carefully start the heat-shrink tube put on in advance on the wire to the connection.

11. Heat it with a lighter, not allowing the flame to touch the wire, and not holding it too in one place on the surface of the tube.

The result is a reliable connection between the two ends of a torn two-wire wire, neat and not too noticeable.

You can, of course, use electrical tape to isolate the cores, but it will be difficult to achieve such an aesthetic appearance of the connection with it.

Video how to gently repair a wire without a soldering iron