Of course, this is said loudly - usually does not replace. But if you need to make such a beautiful case, as on KDPV, the title is fully justified. The author of Instructables under the nickname mickymckicky tells what needs to be done for this.

To realize the miracle of turning a plastic pipe into a body, the master, in addition to the pipe itself and the building hair dryer, needed planks, safety glasses, a hacksaw, gloves, a screwdriver, self-tapping screws, angles and clamps. “Porridge from an ax”, of course ... This particular case is made of a pipe of 100 mm diameter. If you unbend it, you get 314 mm. The original says that the author spent 2.4 m of such a pipe, but either this is a typo, or he made several cases, or it turned out not the first time.

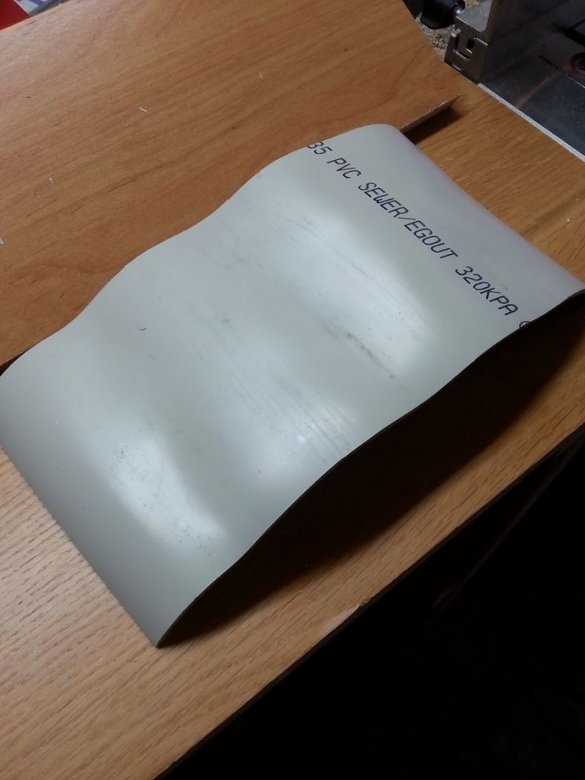

Trumpet:

First of all, mickymckicky cuts off a workpiece of the desired length from it, in which it then makes a cut for extension:

He bends the workpiece gradually, using a building hair dryer, gloves and a plank:

While the workpiece has not cooled, it is placed between two flat surfaces, pressed and left to cool. You won’t even guess that it was once a pipe:

Again, warming up the bending point until slightly softened, bends at a right angle with the help of two planks and clamps, like this:

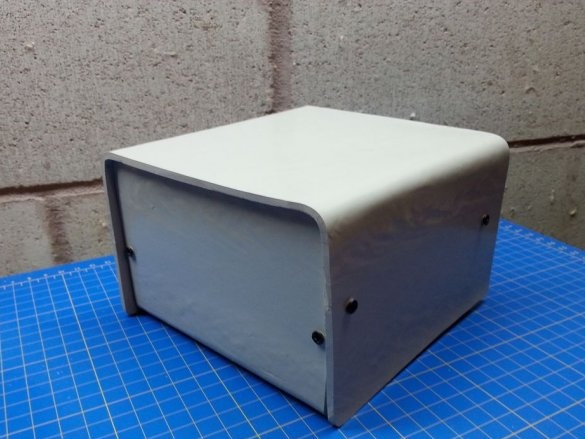

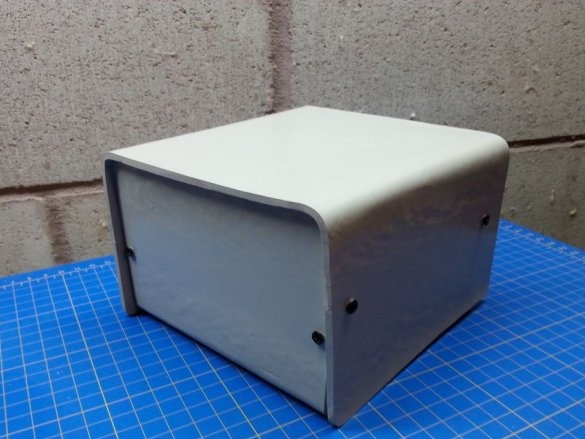

Result:

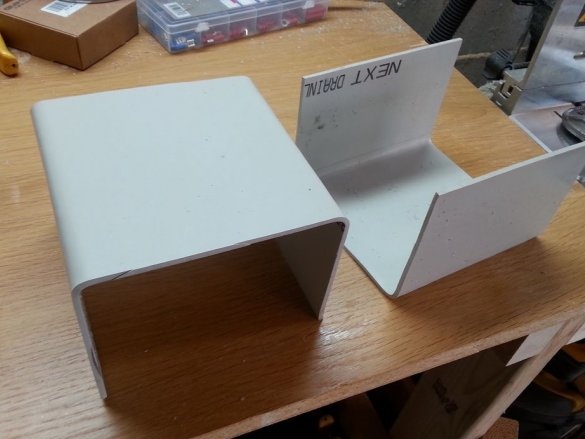

The master does the second bend in the same way, note that for beauty it is better to draw the inscriptions inside the case, where they are not visible:

Ready half of the body:

Both halves:

Before fitting one half, it marks the piece of foam on the other:

Performs fit:

He takes the corners and cuts off the excess from them:

Puts on one of the halves:

And the case is assembled:

And this “damn lump” came out when trying to use a hacksaw blade with too large teeth, do not do this: