In this article, Ivan, the author of the YouTube channel, will tell you how he made a miniature table - an emphasis, an attachment for a grinder.

Materials

- Steel strip 30x4 mm

- Profile pipe 30X20 mm

- Bolts with M8 washers

- Spray paint.

Instruments, used by the author.

- Bulgarian

- Band-saw

- Petal stripping disc

- Cutting disc

- Welding machine

- clamps

- Kern

- Square

- Pliers, vise.

Manufacturing process.

First of all, the author prepares a steel strip of 30x4 mm, two pieces of 60 mm should be cut from it. These will be the attachment of the console to the grinder. Moreover, in length they should be slightly larger than the protrusion on the gearbox.

After marking, Ivan cuts them on a band saw, although it was possible and a grinder.

He tries on the obtained workpieces to a grinder, marks the places for drilling, and corns them.

Makes holes with a diameter of 8 mm on a drilling machine in both workpieces.

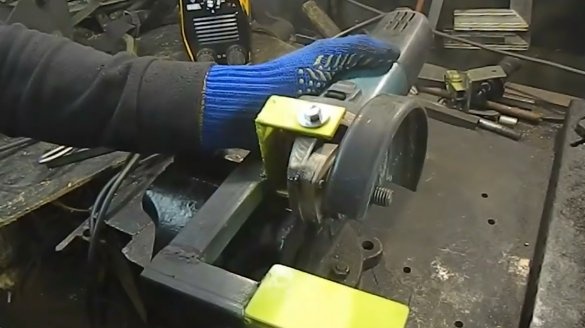

Screws the finished "ears" to the grinder.

Now you need to make another part from the strip, and since the distances between the fasteners are slightly different, the workpiece will have a trapezoid shape. On the one hand, 75, and 85 mm on the other. Presses the workpiece to the table with a clamp, cuts it off.

Here's a trapeze.

Welds the workpiece to the ears.

Now cuts two workpieces from a profile pipe 20X30 mm. Both are 125 mm long.

Now it welds the workpieces together, checking the geometry with a square.

Then the resulting corner must be welded to the trapezoid, but not in the middle, but to the edge.

From one more trimming of a profile pipe does fastening for a vice or a clamp. Welds it to the frame.

The frame is ready, now Ivan cut out such a rectangle from a steel plate. It will be a miniature table - emphasis. Welds the last part to the frame, and cleans the seams.

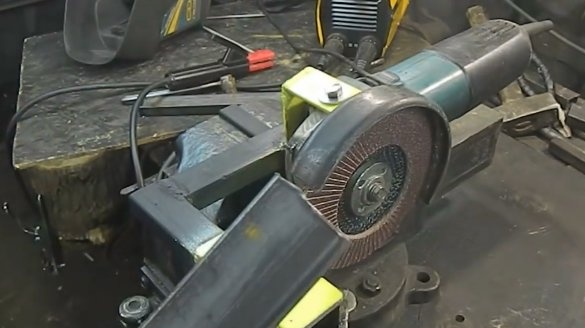

All, device stains with spray paint and sets it in a vise.

Now on the grinder sets the flap disc and starts the tests. It is very convenient to process blanks, because now they do not need to be kept on weight.

And it is convenient to remove burrs from a steel sheet.

But such cleaning discs can remove rust. Very comfortably.

If you do not have a vice - the whole structure can be pressed to the edge of the table with a clamp.

Here is a device turned out by the master.

Thanks to Ivan for the interesting and useful idea of a table for a grinder.

All a good mood and interesting ideas!