Problem 1. Black spots on parts to be glued.

Many newcomers to woodworking are unaware of such a common problem as the chemical reaction of metal, glue, and wood. If you work with long wooden parts that need to be glued together, and use pipe clamps when clamping, then you may have noticed dark or black spots that form at the junction of the blanks, where excess glue has come out.

The fact is that the lower part of the surface of glued wooden parts is in contact with the clamp tubes. When the glue from their joints falls on the metal of the clamp, a chemical reaction begins between it, iron and tannins contained in the wood, causing darkening / blackening of its individual sections.

As a result, the part loses an aesthetically attractive appearance. Removing such stains can be quite difficult, as they can be deeply eaten into the wood.

The solution to this problem is extremely simple. It is necessary to wrap the metal tubes of the clamps with a waterproof film (or wax paper).

It will prevent the contact of wooden parts (and adhesive resulting from them) with metal.

Problem 2. Traces of glue

Another problem that arises for everyone who works with wood is the removal of excess glue. After you glue the wooden parts together and fix them with clamps, it will certainly leak out at the junction.

The author of the channel believes that it is best to remove it immediately by carefully wiping the problem areas with a damp cloth and, if necessary, lightly sand them. If this is not done, the glue will dry out (and possibly turn yellow, leaving spots on the details), which will seriously complicate its subsequent removal.

Many use a chisel or chisel to scrape off dried glue.

However, this method is not too good.This tool must be used very carefully, without much effort and lead relative to the workpiece at the right angle, which is very few. When you remove the dried glue with a chisel, then regularly remove with it pieces of wood that are firmly connected to the adhesive layer. This is due to the fact that the blade edge, even with a slight pressure, immediately goes deep into the tree, digs into it and breaks out chips. As a result, small potholes and bully appear.

It’s best to use a paint scraper in this situation (just make sure its blade is sharp enough).

When you bring them to the junction of glued parts, it removes only the top layer, since the blade does not go deep into the workpiece. Accordingly, he does not pry up pieces of wood and does not break them.

Use a paint scraper to remove dried glue, and the result will be much better than using a chisel or chisel.

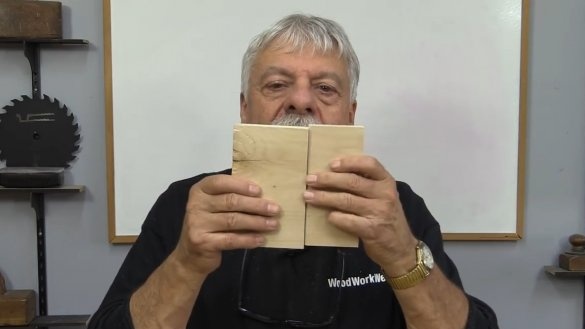

Problem 3. Face gluing

To achieve reliable long-term connection of the end parts of wooden parts with glue is very problematic. The fibers of the end section of the wood absorb a lot of moisture, so the connecting ability of the applied adhesive composition decreases rapidly.

However, sometimes there is no other way out than gluing. The author says that he previously used a special two-component “5-minute” epoxy adhesive.

However, even he did not always provide a satisfactory result.

Then Colin Knecht began to experiment, and soon found an alternative to special composition in the face of ... ordinary PVA glue.

The trick is to use it in a special way. Glue must be applied in two stages. First, you liberally lubricate the end parts of both parts that need to be glued together (the author calls this a “primer” layer). Then you need to wait 10-15 minutes so that their fibers absorb as much as possible and are evenly covered with glue, and he himself is a little dried up. After that, we apply a regular layer, as if we were gluing together simple blanks, and ensure reliable fixation.

Such a two-layer method of applying PVA glue, according to the author of the channel, gives excellent results, providing a strong connection.

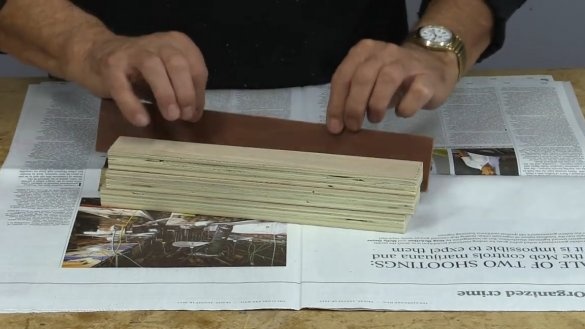

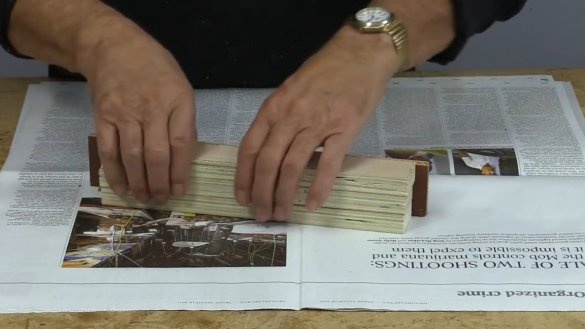

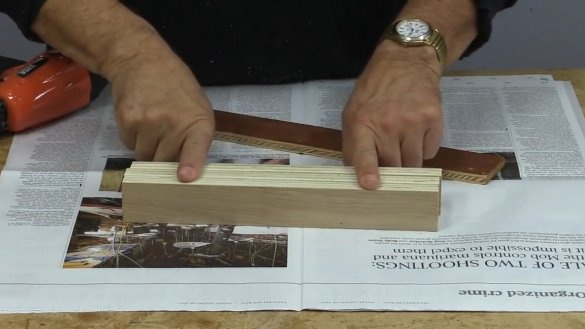

Problem 4. Fixing bonded small parts

If you need to glue several small wooden parts, fixing them with a clamp will be a daunting task.

They will creep in different directions, even from light touches, so that their subsequent alignment can take a long time. In addition, oozing glue from them will stain both the workpieces themselves and everything around.

In order to ensure their subsequent trouble-free fixation, one can do so. First, we glue the parts with glue, connect them together and align them using some kind of board that is suitable for height.

After that, take a nailing gun for woodwork, and connect them to the glued workpieces at the ends.

This will allow you to reliably fix your parts and remove all possible problems associated with the need to align them during subsequent clamping. In addition, there will be no need to worry that the glue will stain everything around and those wooden surfaces that do not need to be glued when displacing the boards.

The author of WoodWorkWeb hopes that these simple tips can improve the quality of your products.

Work with the tree for fun!

Thanks for attention!