In this article, we will look at how the Master made a 12-volt charger from components purchased on Ali. The parameters of the assembled charger are as follows:

Nutrition

-110-220 VAC

output power

-1.25-24 V

-0 - 8 A

- Short circuit protection

- Overload protection

- Overcharge protection

DC Charging

-Constant pressure

- Full battery indicator

-Charge indicator

Now let's see which master used

Materials and tools:

-Acrylic sheet;

-Fasteners;

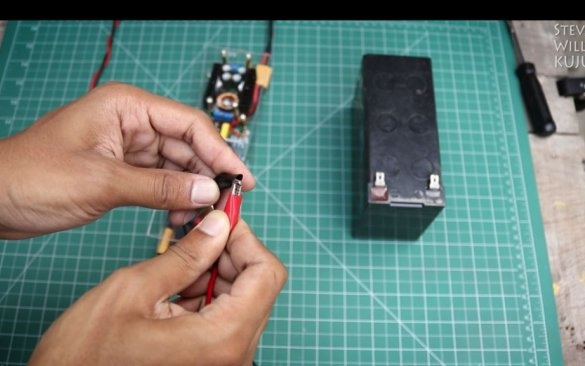

-Heat-shrink tubing;

-Clips;

-Soldering iron;

-Silicone legs;

-Drill;

-Drill;

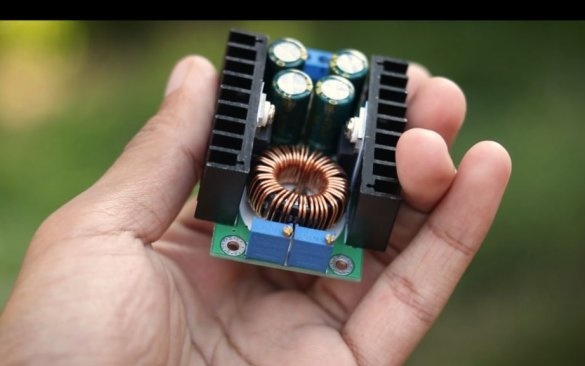

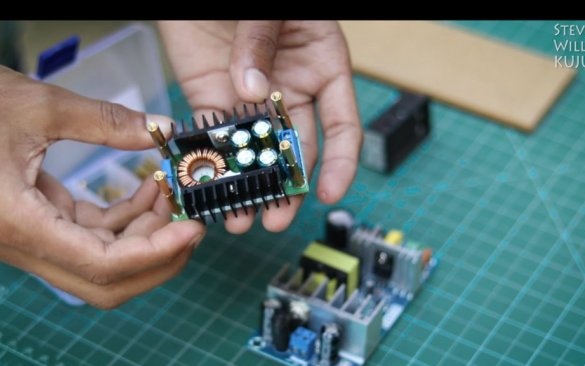

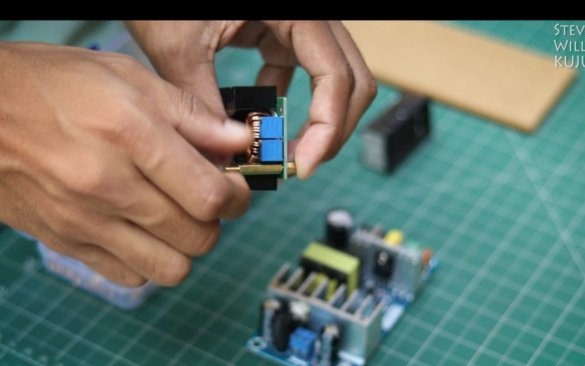

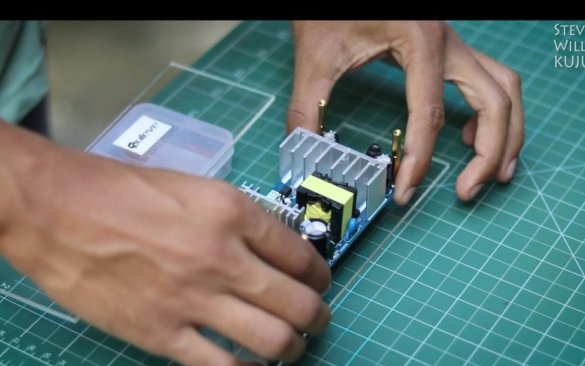

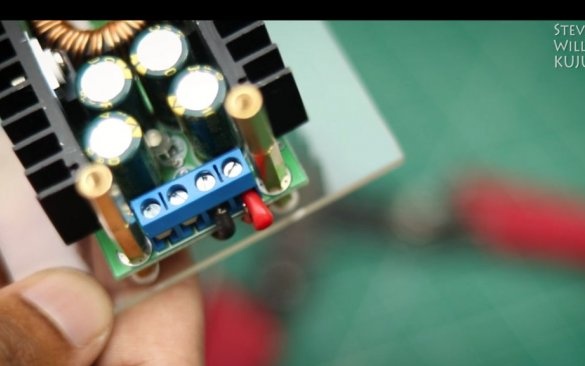

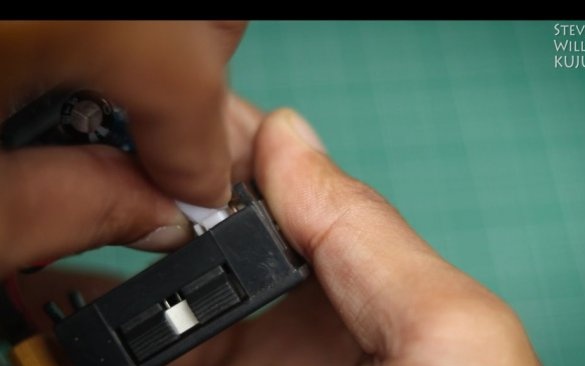

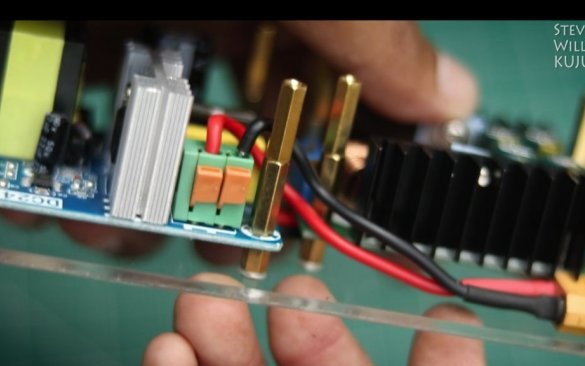

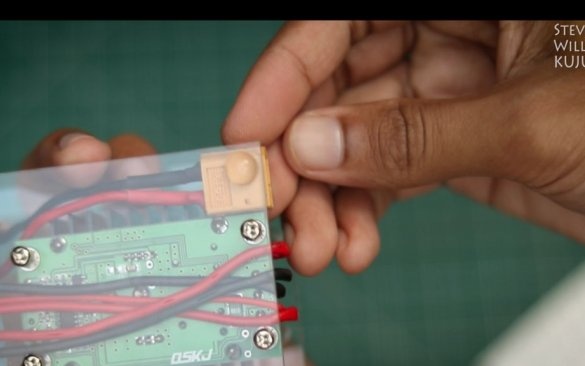

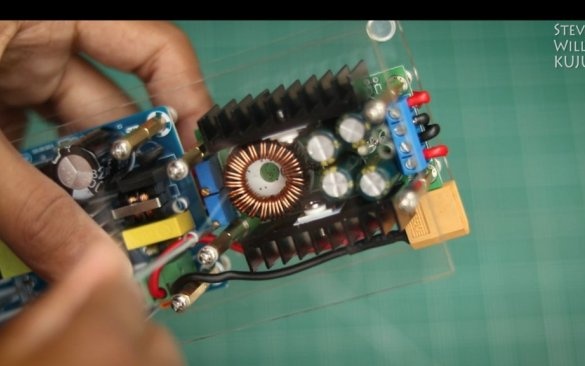

Step One: Fasteners

Fasten the fasteners to the power board and lowering board.

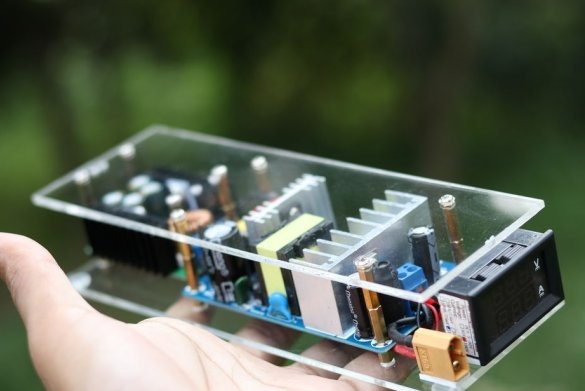

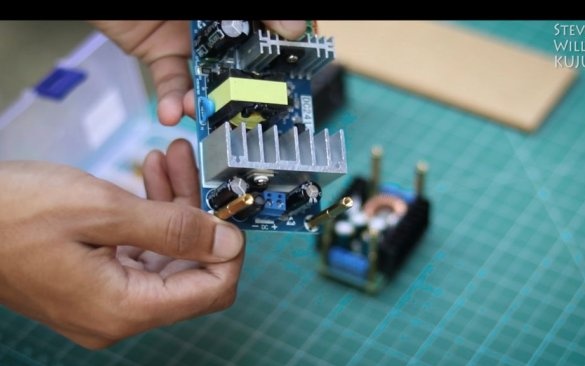

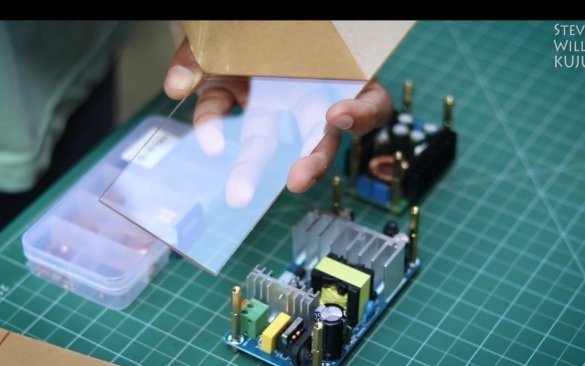

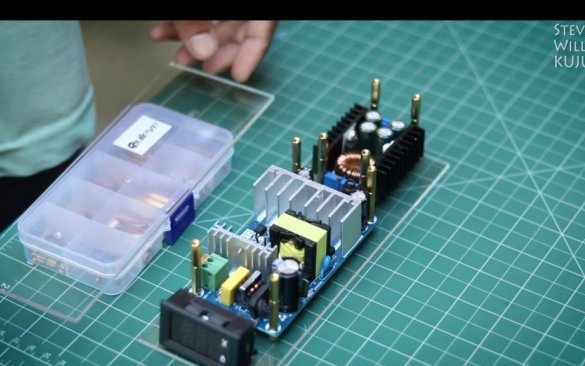

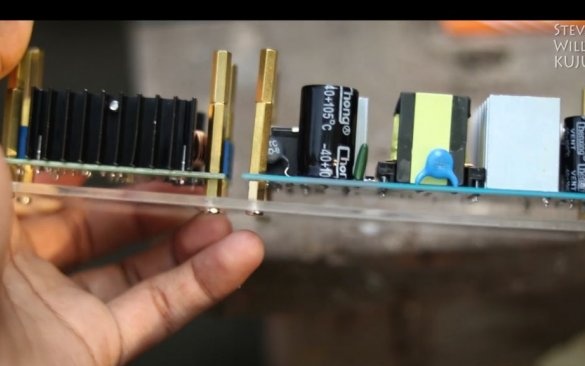

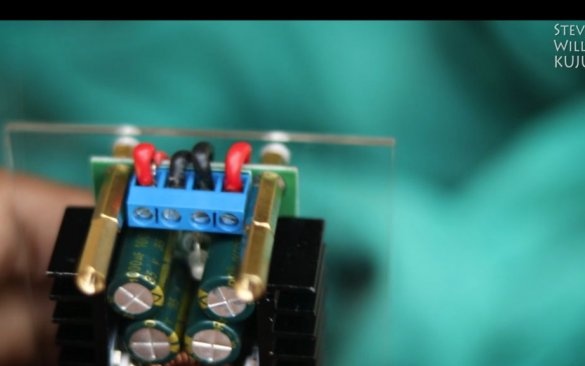

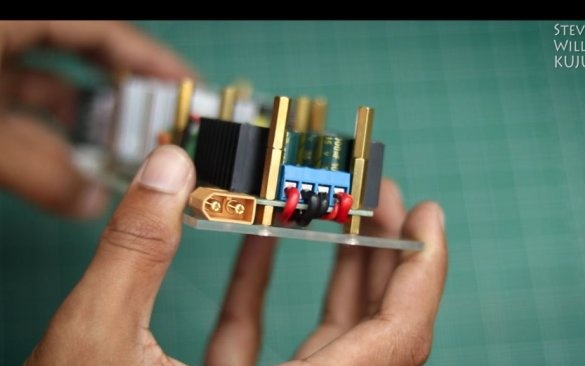

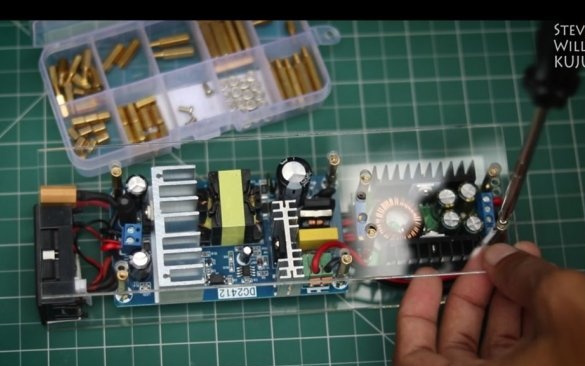

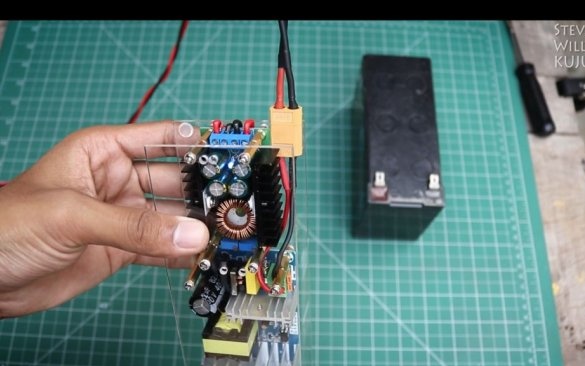

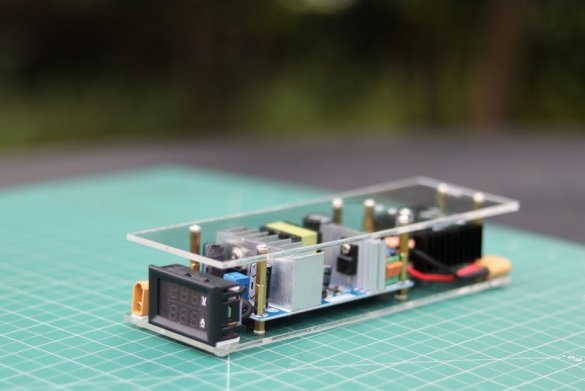

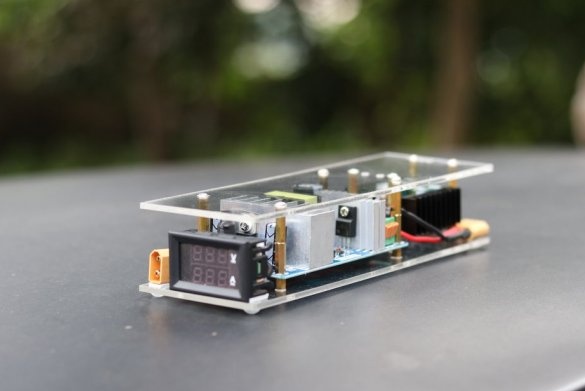

Step Two: Acrylic

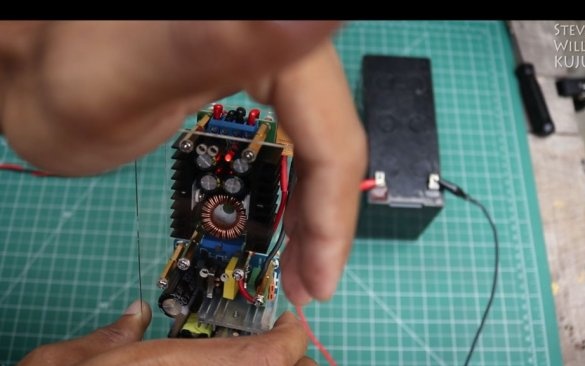

Acrylic will play the role of the body on which all the details are mounted. Removes protective layer from acrylic sheet. Places on a sheet electronic devices.

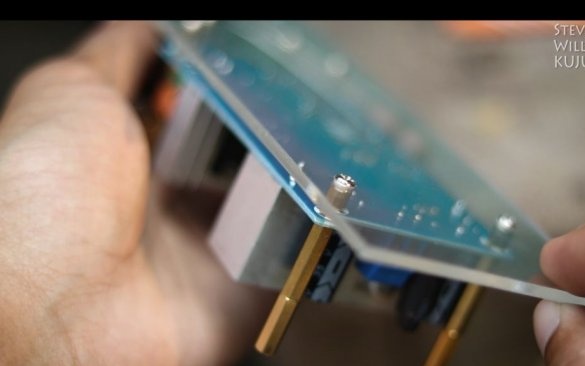

Marks the sheet at the mounting points of the boards. Drills hole marks 2, and then 3, with a drill.

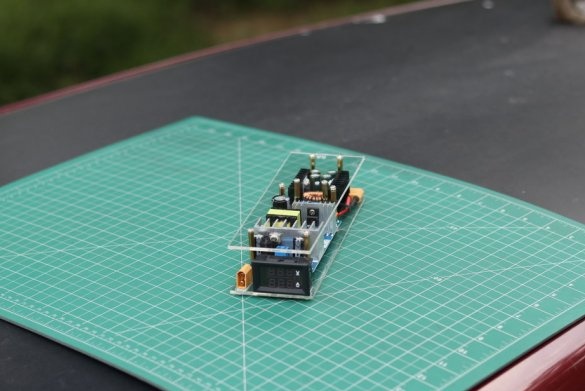

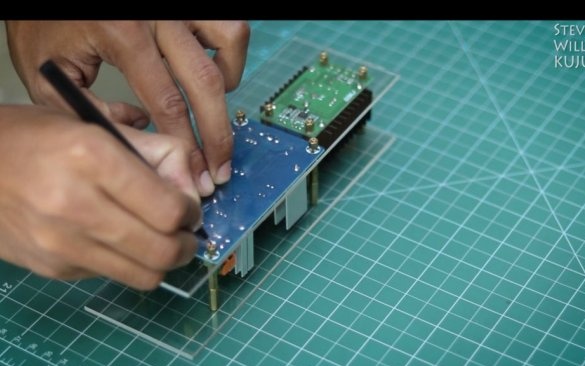

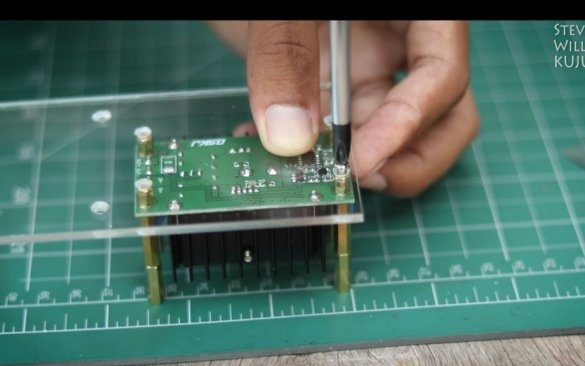

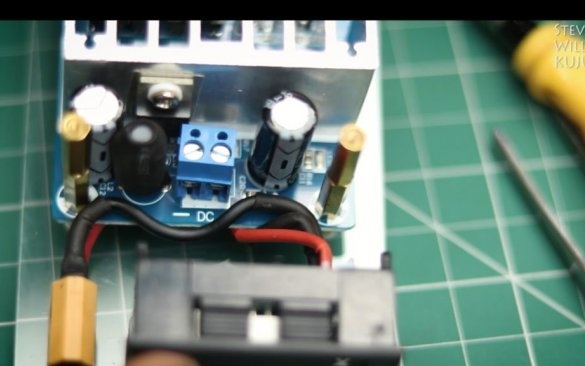

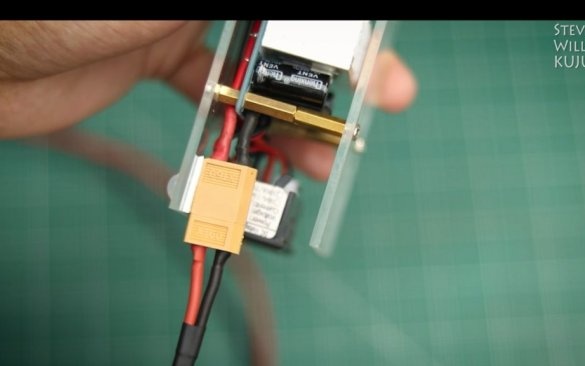

Fastens the boards to the acrylic sheet.

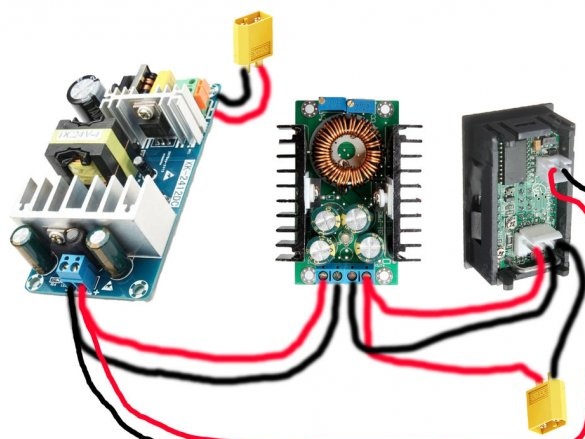

Step Three: Scheme

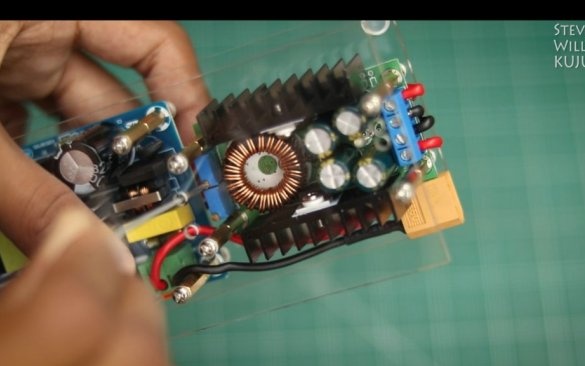

The device is installed as follows.

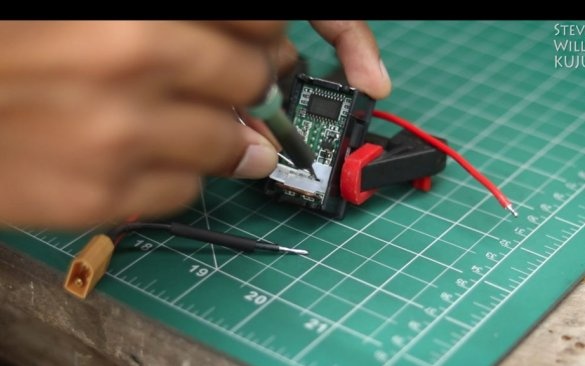

Step Four: Installation

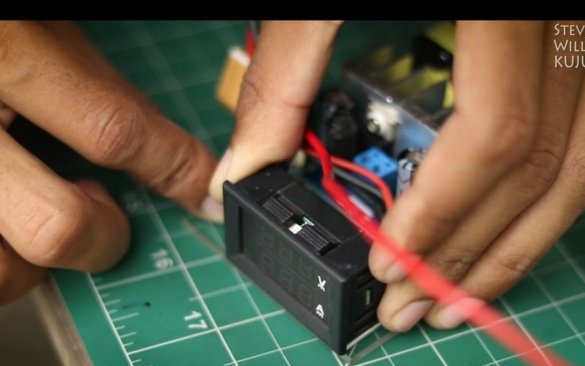

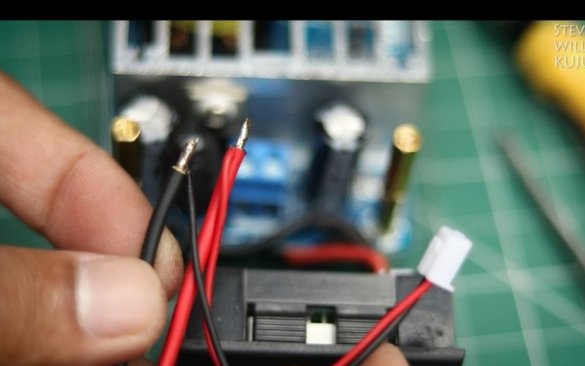

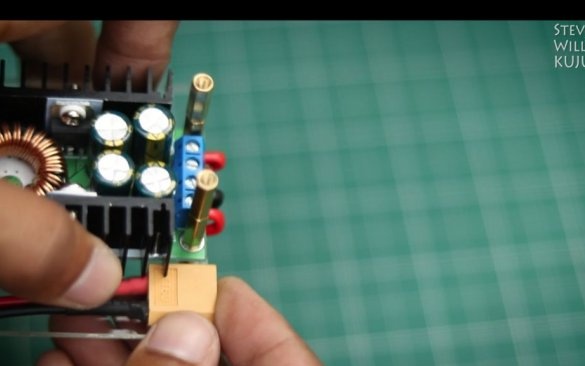

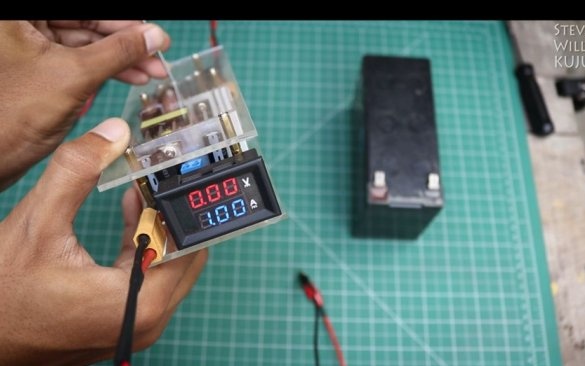

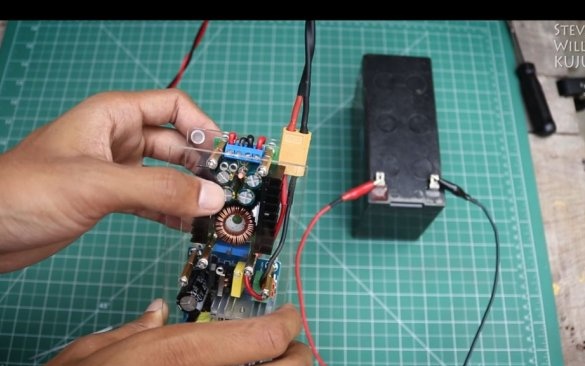

According to the circuit, solder wires to the voltmeter.

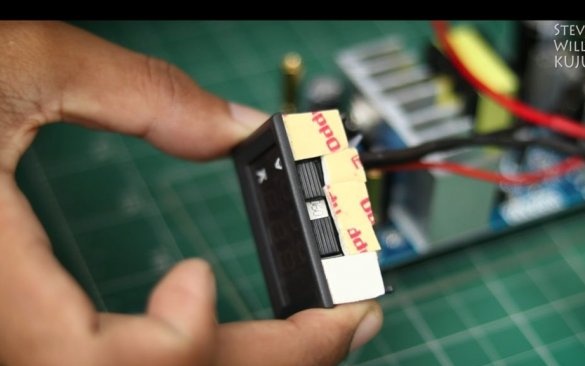

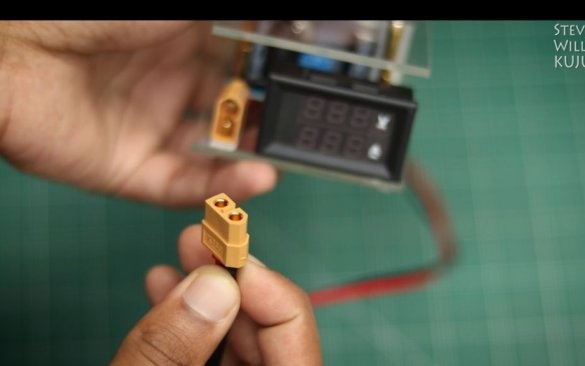

Glues double-sided tape and secures the voltmeter and connector on acrylic.

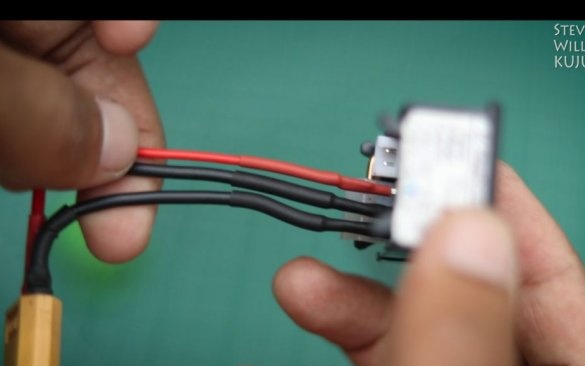

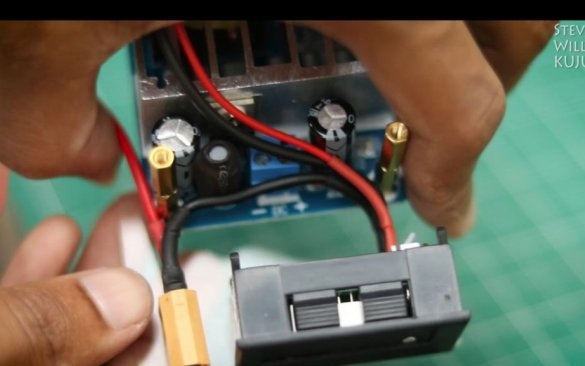

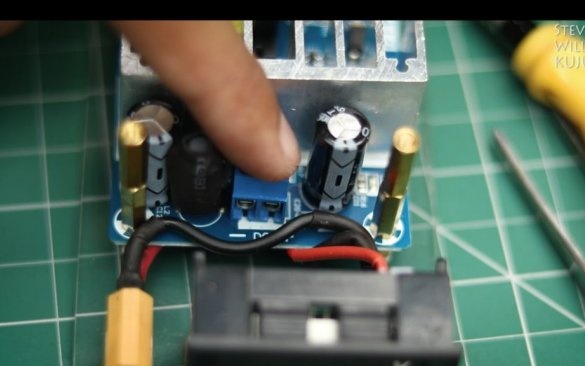

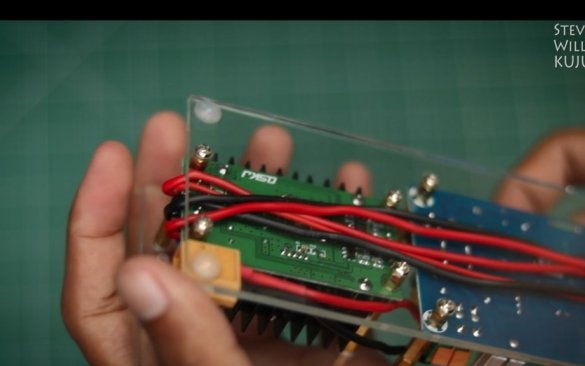

It connects the converter., The wire extends under the board.

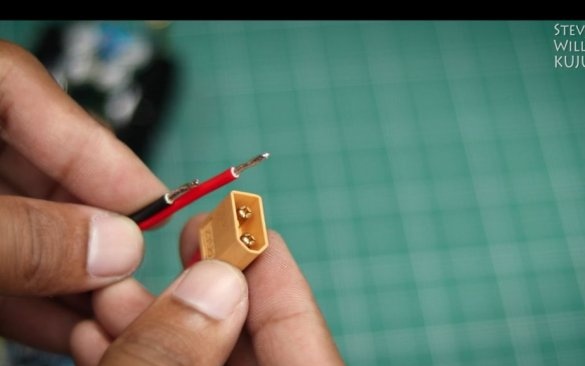

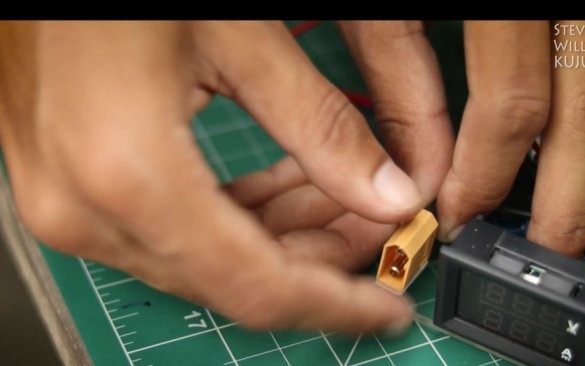

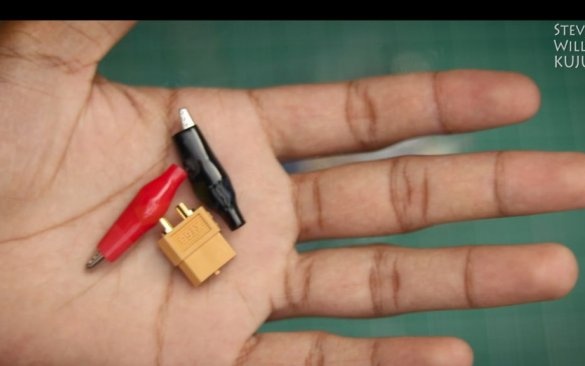

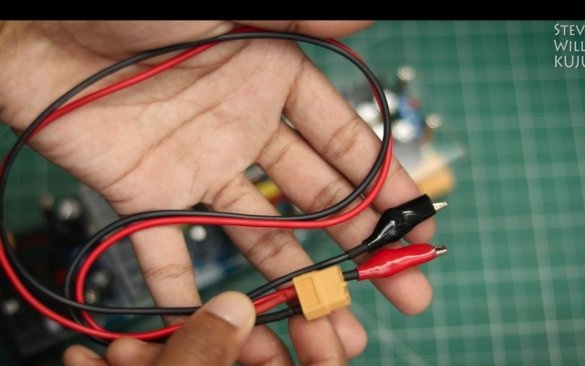

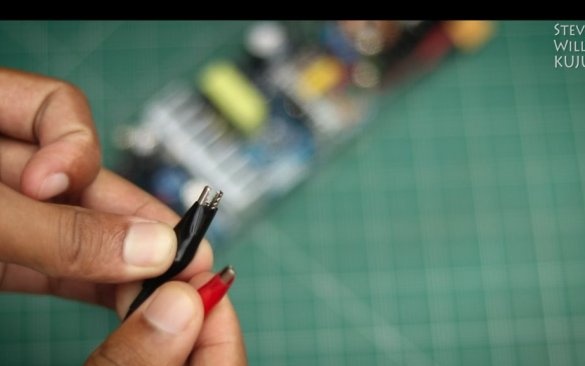

Connects clamps to connectors.

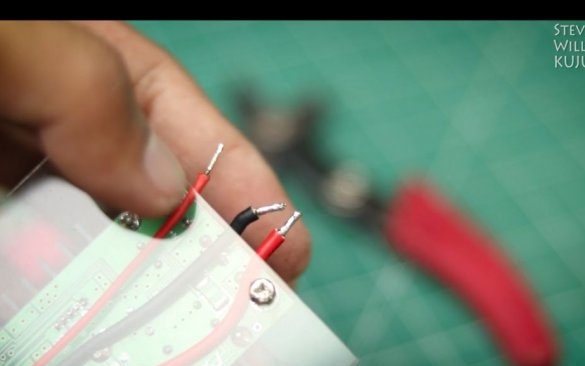

Connects the power cord.

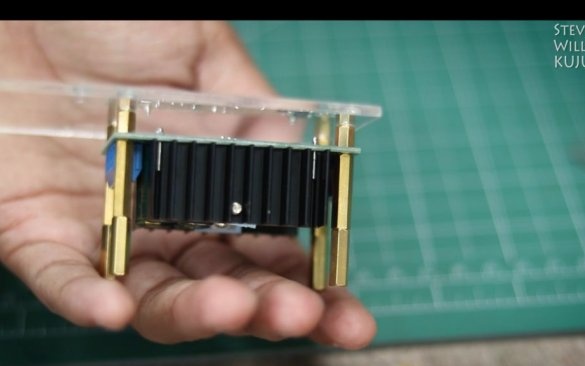

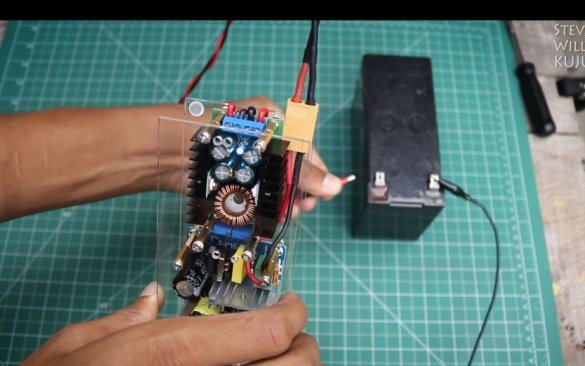

Step Five: Cover

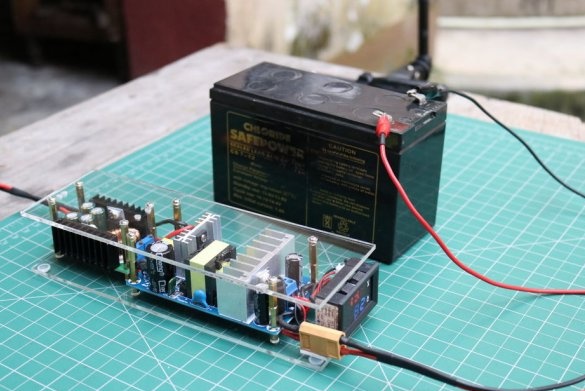

It makes and fastens the lid from acrylic. Adhes silicone feet.

Step Six: Setup

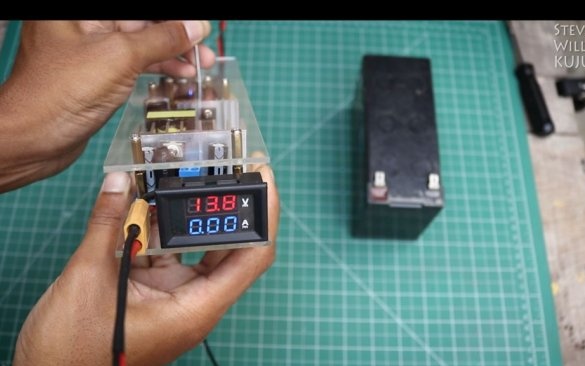

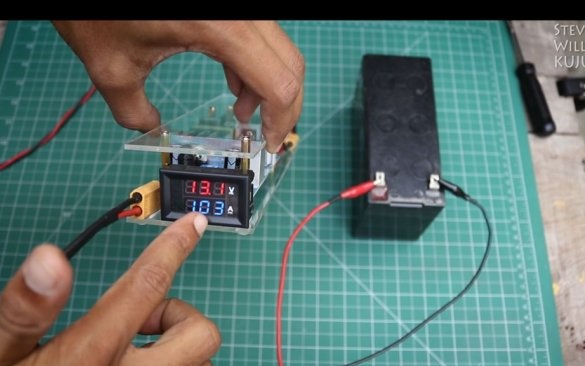

Now you need to adjust the current strength and voltage. The master shorts the clamps and sets the required current with a potentiometer. Then disconnects the clamps and sets the voltage. The voltage of the master sets 13.8 V, the current according to the formula battery capacity x 1/10 = current.

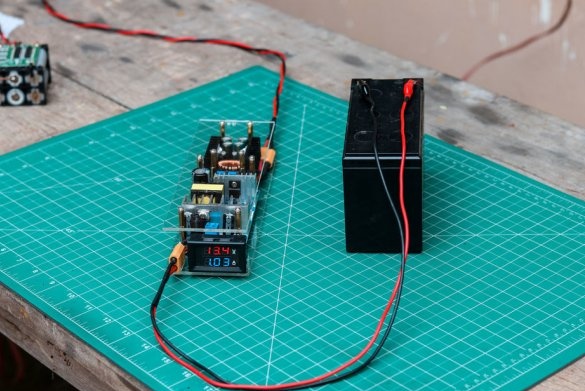

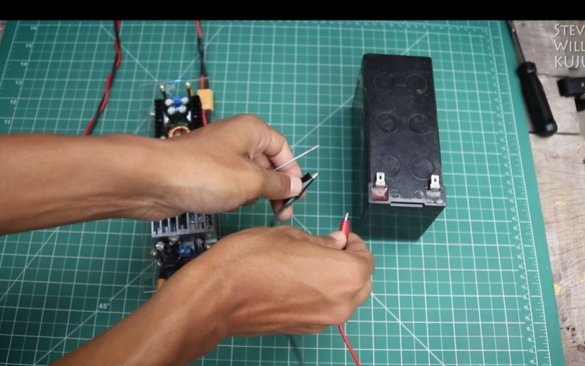

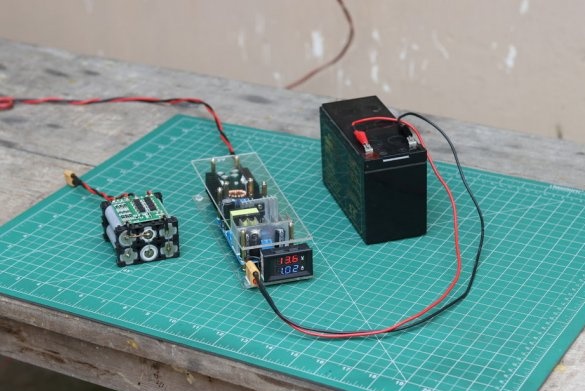

Seventh step: charging

Now it remains to connect the clamps to the battery and charge. According to the author, upon reaching the charge, the device will automatically turn off.

Here is a compact charger obtained from the master. Of course, the security of the device is questionable. At a minimum, it was necessary to carefully consider the case and make it more closed.

The entire process of manufacturing a charger can be seen in the video.