Good day to all. This article will focus on a transformer from a microwave oven. More precisely, how can a spot welding apparatus be assembled from it and what else will this apparatus be capable of. And the author of the YouTube channel Algirdas Vashkelis will help us figure this out. Also, the author will test this homemade with wires of different sections, and it will also show for what other purposes, you can use this unit.

I think this article will be interesting to many. And so let's go, who are interested in reading the article further.

Materials used by the author:

Network cable from the microwave with stamps.

Welding wires with a cross-section of a vein of 25 and 35 squares.

A couple more wires with brands.

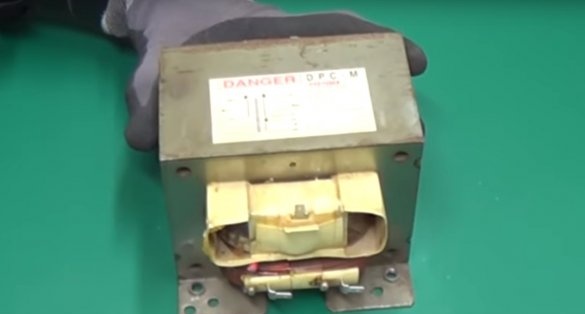

Transformer from the microwave.

Contact button from the microwave.

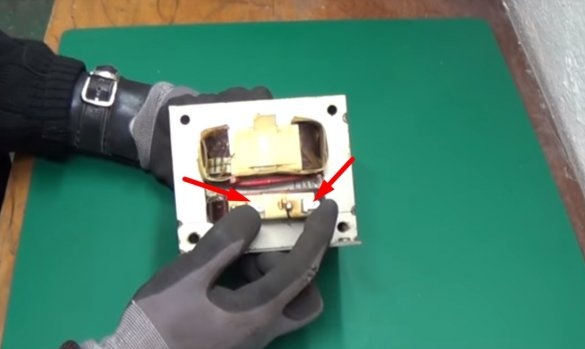

First of all, the author will remove the secondary winding and magnetic shunts from the transformer.

To find out which of the windings is secondary, and which primary is not difficult. The primary winding on such transformers always has fewer turns, with a larger cross-section wire.

It also has two contacts to which a network cable is connected.

The secondary winding has a larger number of turns with a wire of a smaller cross section and more than two contacts come out of it.

This network cable has three conductors, one of which is ground. The author will simply take this vein aside.

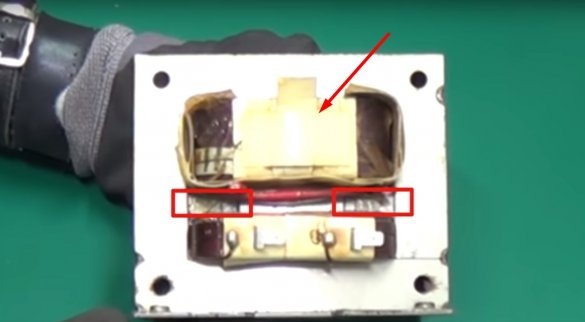

You can remove the winding in different ways, (and he tried them) the main thing when removing the secondary winding is not to damage the primary.

Therefore, it seemed to the author the easiest way to cut the winding with an old chisel, which he had not used for a long time for its intended purpose.

He cut the winding on both sides. And the rest just knocked out.

Then he removed the paper and knocked out the shunts.

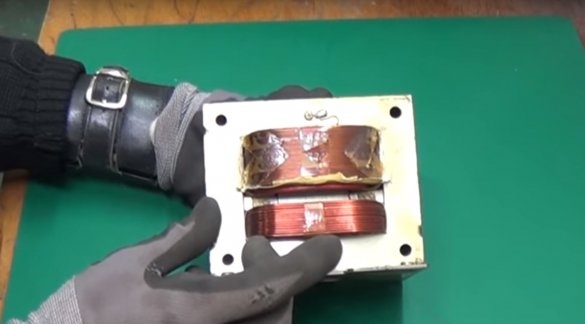

According to the author: some masters claim that when winding a new secondary winding for this apparatus, the direction of the primary winding must be taken into account. Our hero decided to check whether this is really so. Therefore, the author will experience homemade work with the direction of the winding, both clockwise and against it.

For the first test, he took a cable with a cross section of 25 square.

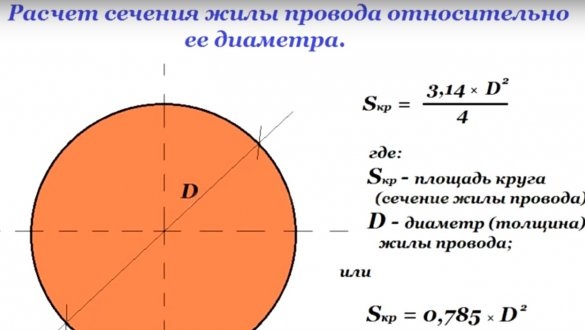

For those who are not aware of the diameter of the wire and its cross section, these are two different things. But in order to find out the cross section of a wire, it is not necessary to be a physicist or mathematician or to bother with different formulas and calculations.

You can simply use this table or similar, the benefit in the network now there are a huge number of such tables.

The result of the cross section of the author’s first test wire.

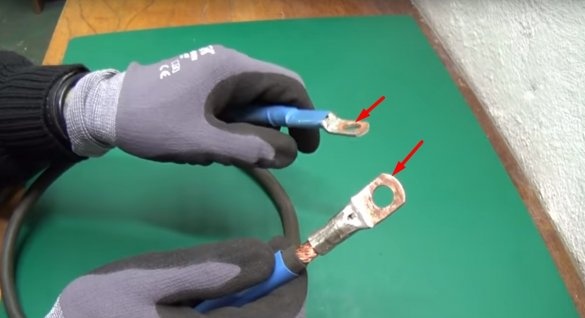

At the ends of the cables, the author installed such tips, then crimped them and put on a heat-shrink tube. (All wires that the author tested have a length of 1.5 m.)

Next is the cable winding: clockwise from the bottom up one turn.

Then I connected the network cable and the button.

And the first test on a self-tapping screw is a diameter of 3.5 mm, a length of 90 mm.

The result is 7 seconds.

Next, a change in the direction of the cable, that is, in the opposite direction to the primary winding, is also one turn.

And a test on the same screw.

The result was the same, 7 seconds. It turns out the direction of winding is not so important, as many say.

Next, the test with the same cable, but with two turns.

The result is 3 seconds.

Bolt 3.5 mm to 70 mm.

Result: 6 seconds.

Next, a wire with a cross section of 35 square one turn.

Test until the bolt breaks the bolt parameters are the same.

The result is 12 seconds.

Next: the cable is the same two turns.

Time 6 seconds.

And in the end, the author decides to make a wire with a cross section of 50 square. To do this, he took two welding cables with a cross section of 25 square each. He stripped them of insulation and twisted them into one core.

Then isolated: first, mica.

Then cotton tape.

And at the end of the heat shrink.

The author was also wearing tips at the ends.

Ready cable 50 square.

One turn.

Bolt again.

The time is 8 seconds.

Next two turns.

Bolt.

Time 4 seconds.

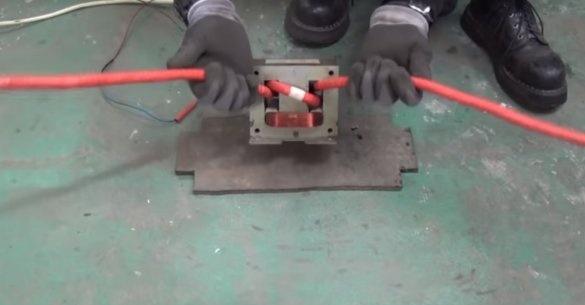

To check the following capabilities of this unit, the author collected contact tongs, but this is a trial version, or as the author called a working prototype.

The electrodes are made of a soldering iron tip with a diameter of 12.5 mm.

As clamps, the author used a copper bus 20 mm wide, 3 mm thick.

It turned out such a home-made installation.

The next test is on a rusty and bolted nut.

After warming up, the nut is unscrewed without difficulty.

The metal square is 10 mm by 10 mm.

The device is also able to warm up.

Well, now the direct purpose of this homemade product. Welding two or more parts.

Test: metal 0.7 mm (from a passenger car body auto).

2 mm plates.

Profile pipe 30 mm by 30 mm, wall thickness 0.5 mm.

And body steel 0.7 mm.

This unit is able to work as a spotter. To do this, one of the ends of the wire should be fixed in any convenient place on the body.

And on the second edge of the wire you will need to install a clamp, which can be purchased at the store or made by yourself. The author uses pliers to demonstrate.

In the future, the author plans to make contact tongs for this device according to this principle. The main thing is to make the electrode holders insulated from each other.

And I almost forgot to clean the contacts with sandpaper.

This article turned out today, I hope it was useful to many. And that's all for me. Thank you all and see you soon!