In this article, Jack, the author of YouTube channel "Jack Houweling" offers you an improved version of a portable air purifier. The compact case is an excellent solution for the workshop. And the first thing that the master will do, he will transplant the “stuffing” of the device into another, wooden case. And then he inserts filters into it.

Materials

- sheet plywood

- Wooden blocks

- fan

- Air filters

- Wood screws

- PVA glue.

Instruments, used by the author.

- A circular saw

- Electric jigsaw

- Clamps, vise

- Drilling machine

- Screwdriver

- Hammer

- Rulers, pencil.

Manufacturing process.

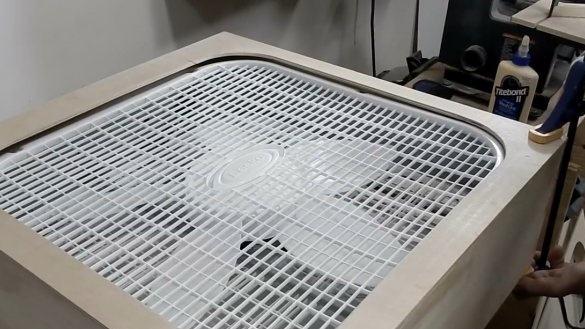

Jack bought such a fan in a square case.

Before you are two purchased paper filters: one collects large particles, the second - smaller ones. Jack notices that he sometimes uses a blower to properly blow out the accumulated dust from there.

Then he removes the speed adjustment knob, one protective grille and the handle from the fan.

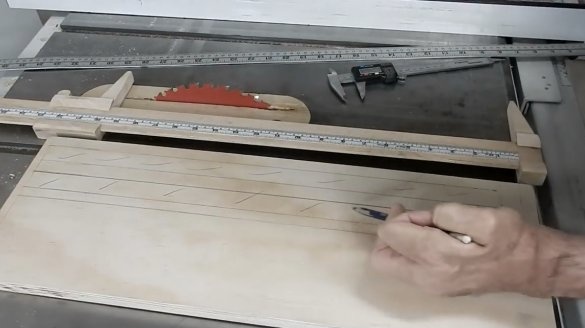

The fan has a case size of 20.5X20.5 inches. For the body will be used sheet plywood with a thickness of 3/4 inch.

Now cuts all the elements of the walls of the body.

To assemble all the elements, the author will use a groove joint, the literal translation from English is “blind rabbit”. Cuts out grooves.

Then he assembles the case.

He makes notes in the places where the filters will be inserted. And these two sections will be cut off.

Jack made the first slot right away.

And this is a test piece of the board on which Jack makes a trial cut to make sure that the stop is precisely installed.

Those places where the saw blade did not reach, he cuts with a jigsaw.

Everything is ready, you can assemble the body for glue.

Temporarily removes the grate, it prevents the layout of the "window" on a sheet of plywood.

Jack again cuts long lines with a circular saw, laying the sheet directly on the saw.

And the turns are cut with a jigsaw.

Installs the frame, glues it and clamps it with clamps.

Now glues filter guides.

Drills a hole for the speed control knob.

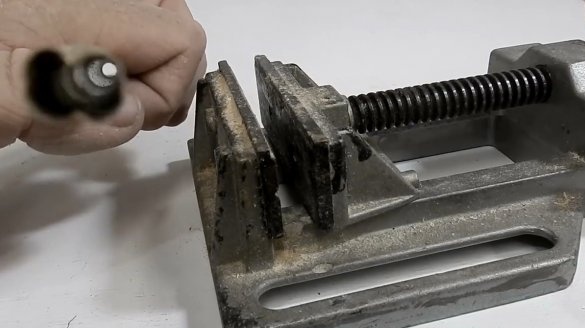

Further, the author adds a new handle to his design. He makes it from a brass tube and a wooden round log. Cuts a circle with a crown, drills a hole for the tube, but not through.

He cuts the tube to the desired size and slightly bends its edges, so that it passes into the hole.

Now he inserts it into the device, everything switches.

Cuts the tube in length, clogs it into a round piece, sets it in place.

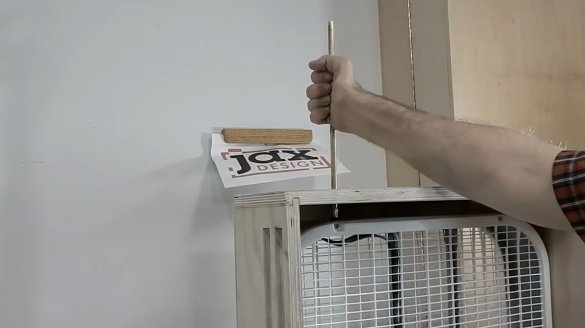

On a band saw, he carves a handle from a wooden block, polishes it, and fastens it to the case.

In order for the filters to easily slip inside the housing, Jack constructs such guides. He mounts one to the side wall, the other to the top. And screw them on the screws.

Now sets the filters in place.

Here he leaves a small gap for the power cord.

Thanks to the handle, the device can be moved from place to place, which is very convenient in a workshop. Wood, although heavier, is more reliable than plastic. Office cold does not blow from him, as from metal things and in the interior it creates a unique cosiness. It remains only to treat the case with wood impregnation.

Thanks to Jack for the original idea of an air filter.

All good mood, good luck, and good ideas!