Good day to all. Today the author of the channel 1000 DIY AND TIPS

I decided to tell us how he put together a budget spotter. do it yourselfwithout any troubles. What was needed for this homemade, as well as detailed instructions and assembly diagrams, you can find out from the article. And so let's get started.

Materials Old used, water tap.

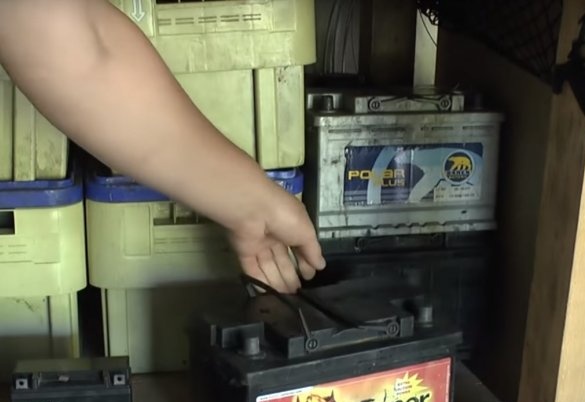

The working battery is 12 V.

Solenoid Relay from a Passenger auto.

A pair of battery terminals.

Cable lugs. You can buy here or here .

And you can make it yourself, from a copper tube.

Welding clamp for mass. Can be replaced.

A piece of brass bushing, a bolt and a couple of nuts. (This option for this unit will be even better).

Normal two-wire wire.

Cable ties.

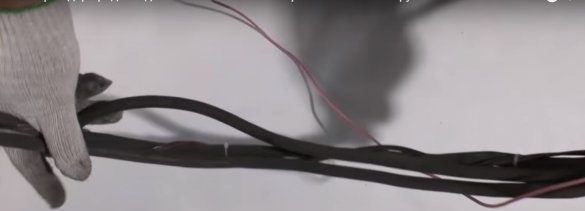

Three pieces of welding cable, two of them 1 m each and one 30–40 cm, with a diameter of at least 8 mm.

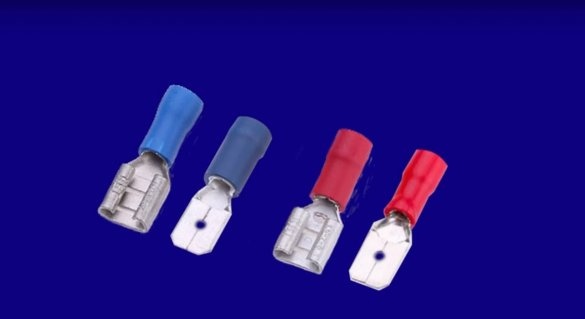

You will also need flat connectors of the type "male" "mother".

And an old screwdriver.

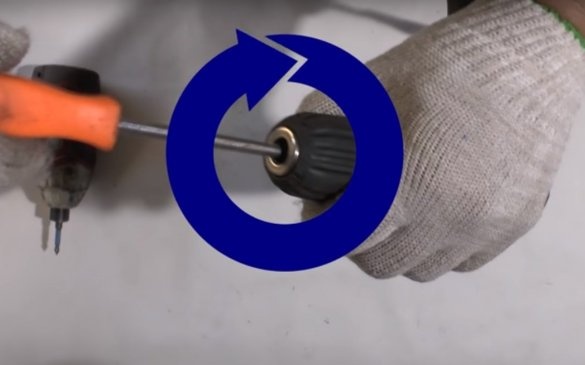

And the first thing the author will make a gun, for future homemade. To do this, he will disassemble the screwdriver.

There may be a screw in the cartridge; it has a reverse thread.

After removing the screw.

The author will clamp the hex key in the cartridge.

And striking it with a hammer, remove the cartridge.

Then he removed the motor with gear from the drive shaft. In this homemade product, it is not useful.

Instead, he welded a piece of metal water pipe. And he made a simple clamp for the welding cable on it.

Then, on the button with the help of a tester, the master found a pair working for a circuit, and connected a two-wire wire to it.

Checked.

In this place on the case, the author made a hole for the cable.

Next, he screwed one of the meter-long pieces of cable to the clip on the cartridge.

After the cartridge and button installed back into place.

Then he assembled the gun.

Button wire and cartridge cable, the author fastened with cable ties, for convenience.

On all ends of the welding cable, he installed lugs.

And squeezed them by the old-fashioned method with a hammer and a turned bolt.

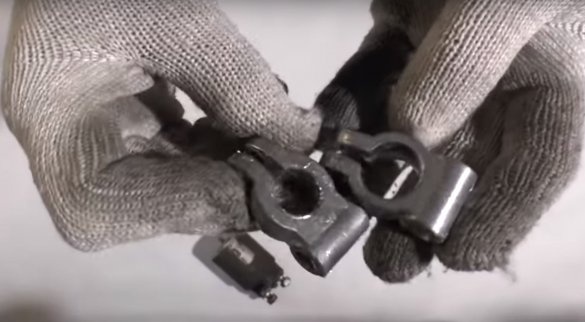

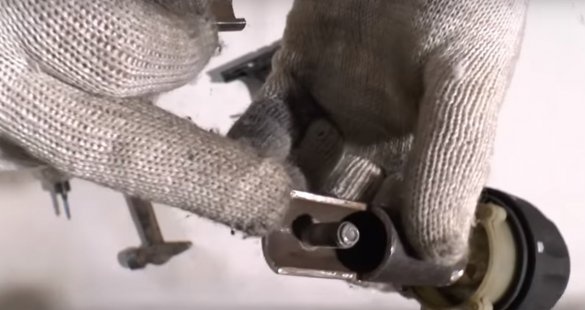

On the solenoid relay, the author will remove this spring.

Anchor, set in place. (Without spring.)

Then, from a piece of tin, he will make such a latch so that the anchor does not fall out.

And install it, leaving not a big gap.

Further assembly. There is a cable coming from the gun.

And the wire from the button.

The cable connects to one of the contact bolts of the retractor relay.

He connected a short piece of cable to the second bolt and the positive terminal of the battery.

Another meter piece was connected to the minus of the battery, it will be mass.

At the ends of the wires going from the button, the master installed flat “mother” clamps and made one of the wires shorter, and connected it to the relay.

The second wire to the negative of the battery.

Who does not understand, see the diagram.

Such a homemade product.

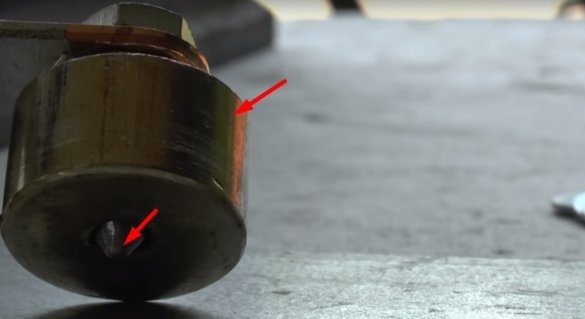

The author made a sting from an old brass tap.

Set the sting in the cartridge and proceeded to the test.

Also, a reverse hammer can be installed in the cartridge of the gun.

Since this device will be used in bodywork, the author made the mass for him himself.

According to this principle, a sharpened steel bolt is screwed into a powerful nut from a brass bar.

It fixes this mass as follows: holding the mass, as shown in the photo, grabs the washer, and at the same time the mass is fixed.

After that, the author will screw the brass washer to the part, thus increasing the mass area, and during operation such a mass does not heat up, since the voltage area diverges across the entire washer.

Test on a car body.

Paint in the workplace should be removed to the metal.

Of course, if the paint is not damaged on the body, it is better to use fungi to remove dents. 73

But in other cases, such a device is not replaceable.

Conclusions of the author after the test. The master used a relatively powerful battery at 80 Ah, but not a new one. On it, the author made a total of somewhere around 240 tacks.

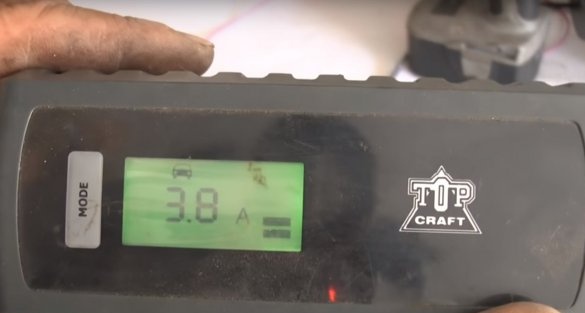

How much the battery was charged before the start of the test, the author does not know, but after work this is the result of the charge.

Also, the author recommends using tips copper, but not aluminum, which he used himself.

The author also does not advise heating the puck to such a state, as this can lead to boiling of acid in the battery, and possibly to its explosion. Take care of yourself and others.

And that’s all for me. Thank you all and see you soon!