In this article, David, the author of YouTube channel "Make Something" will talk about how do it yourself it is possible to construct a curbstone for a gas fireplace. The main materials will be cherry wood and concrete slabs.

If readers want to build a similar structure at home, the author warns, they should first notify the gas company, carefully study the technical specifications and other documents that they will issue. After that, competently choose a place and prepare it accordingly. All these steps should not be neglected for safety!

So, David already had a cabinet for a gas fireplace, but it began to crack from the temperature, only the front part of the structure did not suffer.

Materials

- cherry plywood

- cherry boards

- Armature

- Chipboard plate

- Impregnation for wood

- Acrylic concrete primer

- PVA glue, silicone.

Instruments, used by the author.

- Grinder, cutting disc

- Face mill

- A circular saw

- Miter saw

- Drilling machine

- Orbital sander

- Screwdriver

- Hammer

- Device for drilling inclined holes

- Clamps.

Manufacturing process.

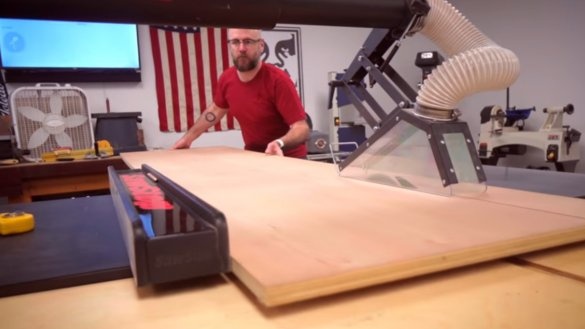

So, the first thing the author intends to do is build a new frame for the fireplace. Cherry plywood panels for large surfaces - what you need! It cuts the panel in width, and then cuts the workpiece in length.

This will be the top of the fireplace.

David used the Fusion 360 program to create the project.

He will use a real cherry board on the facade structural elements. Slices boards with a circular saw, then cuts to size.

David is going to connect the elements of the frame using pocket holes, without the use of glue. Since he wants it to be a collapsible cabinet for the fireplace, so that it can be remade, modified, or restored. In addition, with this type of connection, it is less likely that the frame will lead to temperature. Pocket holes are a master's favorite carpentry technique. And for this he has a special device.

So, the author makes the assembly of the fireplace body without glue, but uses pocket screws.

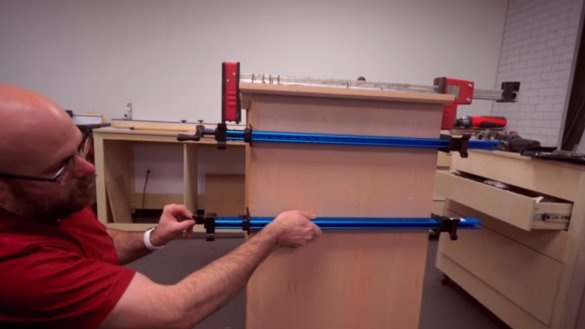

The side parts and the top panel are fixed, facade boards remain. David presses them with clamps, then fixes with self-tapping screws.

He then works on decorating the top of the fireplace. You need to make a frame for her. The joints of the boards are cut at an angle of 45 degrees.

Also decides to make bevels from one angle. The author does this in two passes to facilitate the operation of the milling cutter.

While working on the facade decoration, the master noticed some unevenness from the end edge of the plywood - this is either a cut defect or a factory cut. But when baiting, this can give some clearance. It will not be possible to completely erase this unevenness, since the front part of the plywood will have to pass through emery, and pretty much scratch it.

The author decides, instead of hiding this cavity, on the contrary, hiding it. And he additionally cuts out such a groove.

The front board simply sticks to the body.

Then, for adjusting the sides, the master uses the domino technique: in the end part of plywood and in the sides themselves, he drills oblong grooves with an edge milling cutter, into which flat dowels are then inserted onto the glue.

But with these sockets, he finishes the upper part of the frame by gluing dowels.

For the facade, it remains to cut strips with which it will be possible to close the ends of the plywood.

David then builds the cement slab formwork. By gluing strips, and fixing with a niler.

Be sure to silicone around the perimeter. So that the silicone does not dry out, you can screw the screw into the glue nozzle, and wind it with electrical tape.

The master kneads a standard cement mortar and pours it into the formwork. Get two plates.

In another liquid solution, he immerses steel rods, two in each section. And so everything is upheld for 48 hours.

When the mold froze, the formwork was removed.

And now, such a thing, on some forms, in particular, in the middle where the fittings pass, David noticed some spots. It was decided to place the molds in the sun to dry. And then cover them with a water-based acrylic primer to slightly hide these spots. In addition, along the edge of the molds where the sealant was, the cement also stained a bit. In these places he had to be wiped a little. So, readers can draw for themselves some conclusions on how to properly pour cement into the mold.

And at the same time, and soak all the surfaces of the curbstone.

The most difficult stage of work is to find a way to fix concrete slabs on the inner surface of the front of the fireplace.

The craftsman intends to screw small blocks on the inside of the facade, having previously cut an L-shaped groove into them, into which then a concrete slab will enter. The author expresses the hope that this clamping force will be sufficient to support the weight of the plate.

From boards cuts transitional fasteners for anchors.

By the next step, the master fixes heavy concrete slabs on wooden clamps / clamps and prepares to install a fireplace. The frame of the fireplace should be securely screwed to the wall.

That's it, the cabinet is installed, in the lower part you will need to install another concrete slab.

And glue part of the old facade to the concrete panels.

That’s such a cabinet!

Good mood to all, and good luck!