The issue of saving space does not cease to be relevant. Bulky furniture goes out of fashion and is replaced by more compact and multifunctional options. You can make such "smart furniture" do it yourself.

This sofa bed is made of natural wood. You can also use thick plywood, since it is not always possible to find a board of suitable width. The author used wooden slats as lamellas. Due to their location, the sofa unfolds, turning into a full bed.

In order to make a sofa bed with your own hands you will need:

Materials:

1. wide board for the frame;

2. bars for the base under the lamellas;

3. slats instead of lamellas;

4. furniture screws;

5. wood processing oil (for example, Danish colorless or linseed oil);

6. glue furniture for wood;

7. wooden dowels;

8. putty on wood;

9. Ready-made sofa cushions.

Instruments:

1. miter saw;

2. drill;

3. grinder;

4. a screwdriver and 2 drills: according to the diameter of the screws and dowels;

5. a big vice;

6. conductor for drilling holes at an angle;

7. several clamps of different sizes;

8. putty knife for puttying holes for screws;

9. Lint-free fabric for wood processing;

10 square, pencil, construction tape.

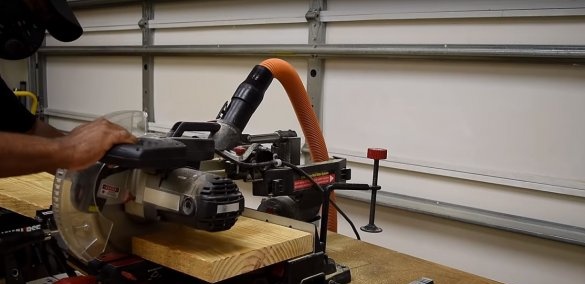

Step One: Preparing Parts

The author uses a fairly wide board in his project. Evenness is cut in this case is very important. Therefore, in order to trim the parts, use a miter saw.

Saw boards into pieces of the required length. Prepare 6 parts for voluminous tall with shelves. The back, like the second item, consists of two parts.

Saw the base parts for the lamellas from the bar. Prepare two sets of slats: for the sofa itself, as well as for its folding part.

All parts should be carefully sanded using sanding tape with a grain of at least 220. Pay special attention to those parts that you plan to process with oil. If you use a stain, the surface should be perfectly smooth.

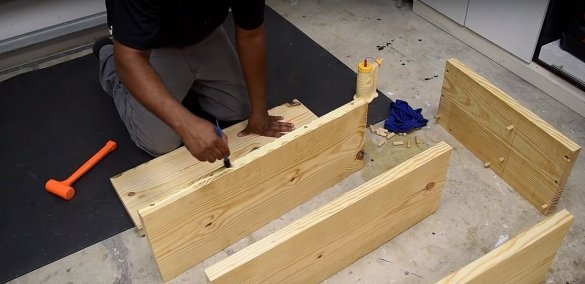

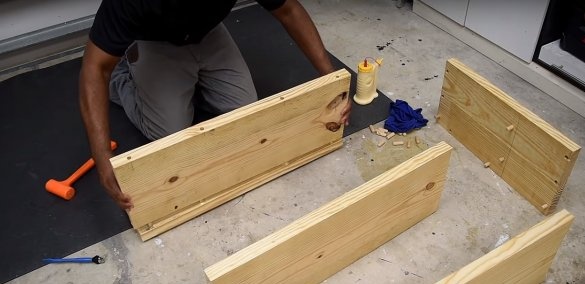

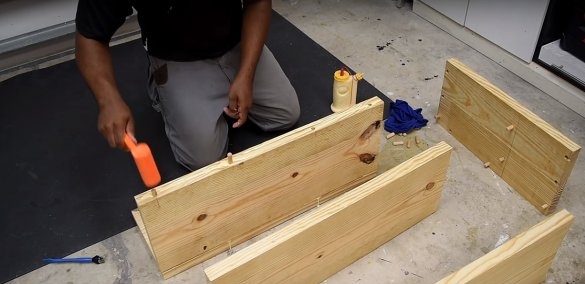

Step two: assembly of the main frame

The frame is assembled on dowels. The author uses a non-base method of fastening parts joint to joint. To make inclined holes for the screws, use a special conductor for drilling (see photo). Also choose a drill for the diameter of the dowels that you use. The dowel should fit into the groove rather tightly.If you use a hammer to put it in the hole, then the drill bit is selected correctly.

Assemble and glue the back and flat side of the sofa as shown in the photo. Be sure to use clamps during drying.

Collect voluminous past with shelves. The upper part of the past is attached to the sofa frame on dowels.

Dock the parts on a flat surface and assemble the main frame of the sofa using screws. Let the glue dry and proceed to the next step.

Step Three: Puttying and Oiling Wood

Screw holes must be puttied. Use a spatula to quickly level the putty. Let the mass dry and grind.

The author uses Danish Watso oil. It dries quickly enough and protects the tree well from moisture. Colorless oil emphasizes the texture of the tree, preserving its original shade. You can also purchase tinting oil.

Apply 1-2 layers of oil with a period of time for drying. Each time, remove excess oil with a dry, lint-free cloth. For application, use a wide brush, cloth or ordinary kitchen sponge.

Step Four: Sofa Bed Base Unit

Proceed to make warns under the lamellas. All parts are attached alternately to the frame, joint to joint. In order to fix the corners during drying, temporarily screw the support from the scraps of the boards. It will not allow the details of the frame to shift.

Fasten the lamellas to the base. In order to correctly calculate the distance, between two lamellas, lay one lamella flat and two on the edge, as shown in the photo. In the final version, when folding the sofa bed, the lamellas should converge with a small gap.

Fasten the narrow board flush with the slats using glue.

Step Five: Making a Sliding System

Temporarily lock into place the main part of the sliding system - a wide facade board. To do this, temporarily attach two or three stops and lower the frame to the stops so that they press the board to the floor and it does not move during further work.

Begin to fasten the remaining lamellas as shown in the photo - with a gap. Be sure to check how everything works. If the folding sofa is not as comfortable as you expected, you can use the wheels on the retractable part. To do this, the width of the front part will have to be reduced.

The sofa bed is ready! Use ready-made sofa cushions or a pair of narrow mattresses to create a soft base.