Today’s New Year’s article, in which we, along with Maxim Kozlov, the YouTube author of the channel, will sharpen a couple of products in the form of such snowflakes embedded in epoxy.

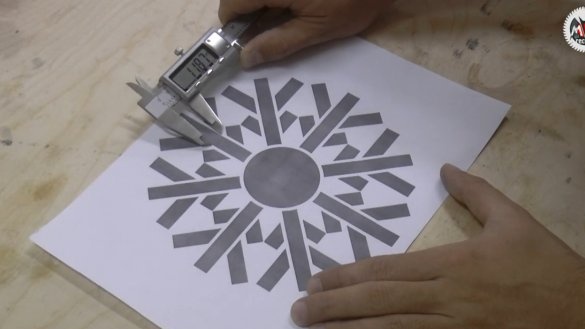

The author pre-painted the classic snowflake shape on a computer and printed it in a 1: 1 format, since the print will be used to position the parts under the fill in order to comply with all the gaps.

Then the master selected several blanks from semi-finished products for cutting segments and cut into bars of equal thickness. The wood component was based on thermal ash, as well as a pair of beech and amaranth blanks. Then he set up the circular saws for cutting the parts themselves from these bars.

Since all the angles of the parts were either 45 or 90 degrees, then with minimal waste everything was cut rather quickly. Further, after rebuilding the emphasis, new lots of parts, but of a different length, were cut off from the same bars. But at the end, from what remains, cut into the size the rays of snowflakes themselves. Thus, from a completely small blank of thermo-ash, we got almost all the details except the central element, under which another 1 piece of the board went.

The author decided to polish the ends of the ray details a little on a spindle machine so that they more harmoniously mate with the center. Then he cut the parts for the second product, where he had already applied several types of wood: beech, ash, thermoash and amaranth. The latter, as a result of the finish, almost merged with thermal ash, this should certainly be taken into account and more contrasting breeds should be used, but it tastes and color.

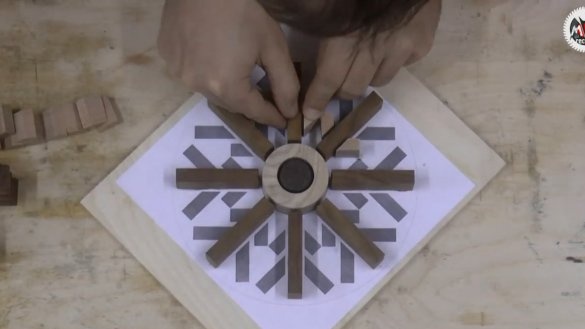

In such works, it is necessary to make gaps between the parts, as this facilitates assembly before filling with resin and gives the product airiness in the end. And in principle, the wider the resin sections between the wooden elements, the better, because when turning and grinding on thin sections of epoxy, cracks very often occur due to radically different expansion coefficients of resin and wood.

The master decided to complicate the central element a bit by drilling a hole in it for inserting an additional contrast detail from wenge.

As the base for the fill, we will use 10 mm plywood, to which it is necessary to glue the printed drawings in advance.

And finally, when everything is ready, you can fix all the details.The author used Cosmofen glue, which is much faster than the wood glue he used before for this purpose. Fixing wooden parts is simply necessary, because during pouring, they simply pop up.

Usually, thin mdf is used as the base, but since the edges of the future product were planned from resin, sealing on the elements did not fit, so I had to drive in a circle of cloves for which plywood was needed.

Accordingly, masking tape was wound around these cloves, which is great for sealing the mold for filling. Well, as always, the seam was coated with silicone sealant.

Particularly zealous when hammering nails is not necessary and after all they calmly get pliers. Without waiting for the silicone to dry, you can begin to fill the epoxy.

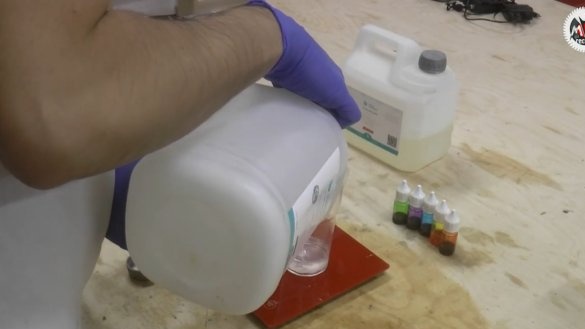

Whatever resin you start working with, you should always practice pretty much in various applications, and most importantly, carefully read the instructions, then the result will always be positive. But all this concerns the turning of the resin. If we are talking about popular river tables, then everything is an order of magnitude simpler, and it is worth remembering only about time, layer thickness and pouring temperature.

There is no need to rush here, we fill it (as the resin manufacturer advises) with 1 cm layers per casting. Every 12 hours a second layer and so on. As a result, there are no problems, and if the composition is clearly tinted, the boundaries between the layers are not noticeable at all.

A day after pouring the last layer, the product can be processed. Also, layer-by-layer filling makes it possible to get rid of the preliminary primer of parts, and especially when there are so many of them (as in this case). That is, when pouring the first layer, when air starts to escape from the ends of the tree, with the help of a stick it is possible to smear all the ends with the same resin, which, when pouring the subsequent layers, will relieve you of bubbles almost completely.

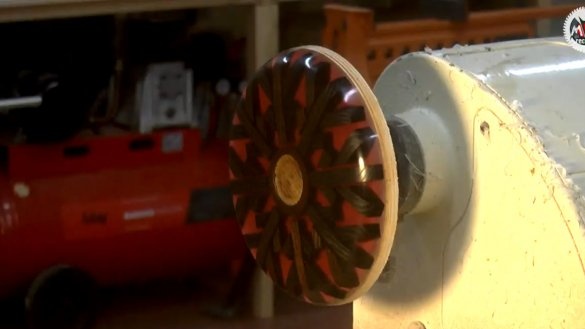

When the resin has completely hardened, we cut off all the excess in a circle so that it is possible to find the center of the product for landing on the faceplate. At the same time, we are preparing the grinding machine for work, pouring water into the tank, and while the stone is saturated, we change the cams on a small cartridge.

When turning pure resin, a real new year begins. Why not confetti this endless ribbon flying out from under the cutter?

It’s not always possible to control this “stream” and most often the whole thing flies straight into the face, while it is electrified and sticks to the mask, from which the view gradually decreases. But this is all temporary, until you get to the tree, there is already more familiar shavings. The process is of course incredibly dirty and dusty when it comes to grinding.

When grinding the resin, it is not necessary to overheat the surface, in order to avoid cracking of thin walls. Therefore, it is better to spend more time grinding, allowing the surface to cool between touches of sandpaper.

The thermoash looked simply gorgeous, and even the author did not want to cover it with oil, since everything turned almost black under the oil. But without coverage in any way.

After processing, the amaranth also practically merged with the thermo tree, but as you know, after a while it should return its lilac color.

Since all of our wooden parts stick out, we must let the oil penetrate as deep as possible so that it does not come back under the action of centrifugal forces before polishing it on the revolutions, and then cover it with wax.

Well, as for the use for food purposes of products with epoxy resin, then the author recalls that this is a purely decorative story. Although purely theoretically, if you cover the whole thing with a special food varnish, then quite.

With the internal bore, as always, we remove the plywood substrate and carefully grind it, watching the thickness. These blanks were rather thin, including, therefore, plywood was used, which allowed the use of small self-tapping screws for fixing the faceplate. It is also very important with such small ledges under the cartridge to make sure that there is no oil or wax, otherwise the part will simply turn on the cartridge.

The edges of the product turned out to be less than a millimeter thick, from which another nuance of resin surfaced.Either because of overheating, or because of centrifugal forces, but when the product cooled down, the edge turned out to be a little wavy. On the one hand, this is a kind of chip, but on the other, you need to be prepared for this. In general, such a thickness of the resin looks very interesting and a color gradient is obtained.

Using this technology, for example, by increasing the thickness of the workpiece, say up to 60 mm, it would be possible to cut this workpiece into a dozen pancakes and get Christmas tree decorations, of course, with a smaller diameter. At the same time, it would be enough just to drive them through a drum grinding machine and varnish. You can also create various compositions such as a kind of decorative stained-glass windows, in general, the theme for creativity is very wide, the most important thing when working with resin, do not forget about respiratory protection.

These are the plates, saucers or candlesticks that you like. Most importantly, with this technology you can endlessly fantasize. And in the new year, the most important thing is that all fantasies come true, and dreams come true. And of course good health, and success. Thank you for attention. See you soon!

Video: