In this article, Alex, the author of YouTube channel "ThisWoodwork" will tell you how he made a wooden case for watches, and a bracelet to him. Such a case and bracelet is much nicer to wear than a metal one.

Materials

- Mahogany veneer

- steel wire

- Second glue

- PVA glue

- Impregnation for wood

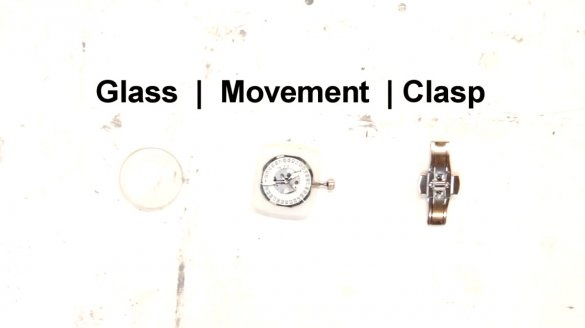

- Glass, clockwork, clip for a bracelet.

Instruments, used by the author.

- Drilling machine

- Forstner drills

- Belt sander

- Grinding nozzles

- A circular saw

- Cautery on wood

- Caliper, chisels, files

- Lathe

- Sandpaper

- clamps

- Hacksaw

- Vise.

Manufacturing process.

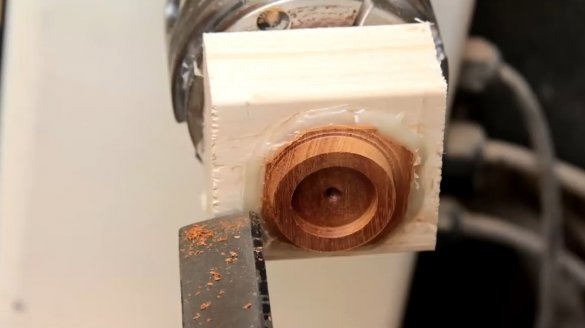

First, Alex begins the manufacture of a watch case. He glues two different types of wood together, and clamps the workpiece with a clamp.

After the glue dries, it drills the central part for the mechanism with Forstner drills. The groove for the glass and the back cover also does.

Trying on a glass.

Marks, and cuts the corners with a hacksaw.

It turns out here is such a blank for the case.

Then cuts through the upper plate to form a round bead for the glass.

Removes excess material with a chisel.

Forms slopes for fastenings, files the edge of the edge.

Now it processes the workpiece on grinding nozzles installed in the drilling machine.

Starts making strap links. Makes a blank.

Then he lowers the saw blade, and cuts out the grooves in the bar. It turns out the profile of the links.

It processes the grooves with sandpaper, removes excess material with a chisel.

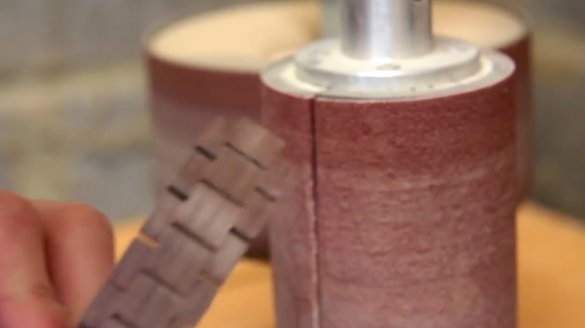

Now cuts the profile into links, polishes them on a tape machine.

This is how the bracelet links are tightly assembled.

For the manufacture of connectors with a clip, cuts two ears off the workpieces, polishes them.

Marks out grooves for connectors, cuts them out.

Drills holes in the connecting links. Trying on to a clip.

Then, placing a piece of cardboard between the links, drills holes for the axes in them. Inserts wire and bites.

Cut the ears on the body, grind it with a file.

Drills a connecting hole in the ears and bracelet. He tries on a bracelet, inserts a wire.

Cleans the protruding edges of the wires on a belt sander, polishes the bracelet.

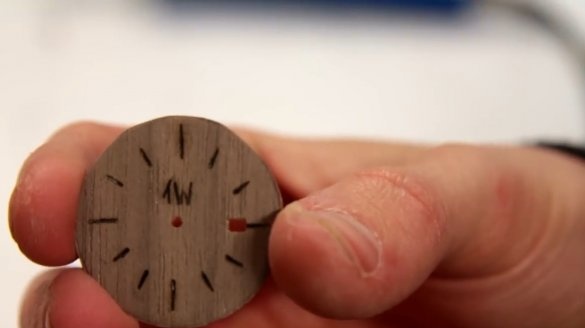

Alex decided to make a dial out of veneer. It just presses it out, clamping it in a vice with a steel pipe.

Drills holes for the axis of the arrows, and a date window.

Using a wood burner, marks the dial.

Then he grinds the back cover on a lathe, polishes it.

Apply logo and date of manufacture.

Tries on the mechanism, cuts out a groove in the back cover.

Drills a hole for the adjusting screw in the side wall of the housing and installs it.

Closes the lid, sets the arrows.

It disassembles the case, impregnates all the wooden elements with oil.

After the oil has dried, the dial and glass are glued onto the second glue.

That's all, you can wear a watch!

Thanks to Alex for a wonderful workshop on making a watch case and bracelet!

Good luck to everyone, interesting ideas and good mood!