Hello everyone, in this instruction we will discuss how do it yourself You can make a simple automatic hammer. With it, you can forge small items, but if you make a bigger hammer by a similar principle, then it will be more powerful and you can make larger items on it. The hammer is driven by a small one on the battery.

The design is very simple, an eccentric is fixed in the drill chuck, which raises the hammer. The hammer returns to its original position with an elastic band, which can be installed in three positions, thereby changing the impact force of the hammer. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- hammer;

- a larger hammer (for anvil);

- ;

- elastic band (you can use a car hose);

- screws;

- boards;

- sheet metal (for clamps);

- bolts, etc.

Tool List:

- jigsaw;

- drill;

- compass, ruler, pencil.

Manufacturing process homemade:

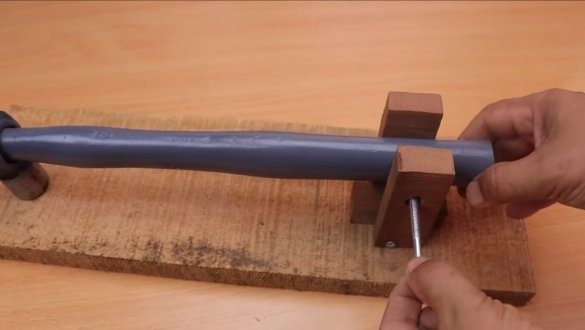

Step one. Hammer bracket

The hammer needs to be hinged by the back. The basis for the machine is a board. And the bracket can be made of bars or boards. We twist it with screws and fix it on the base. We drill a hole in the handle of the hammer, and a screw or similar rod can be used as an axis.

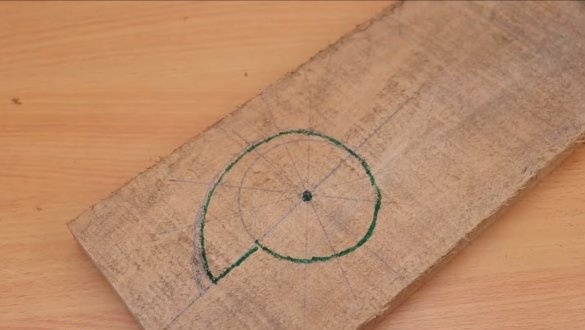

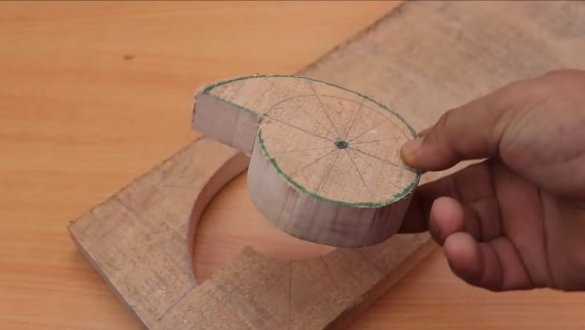

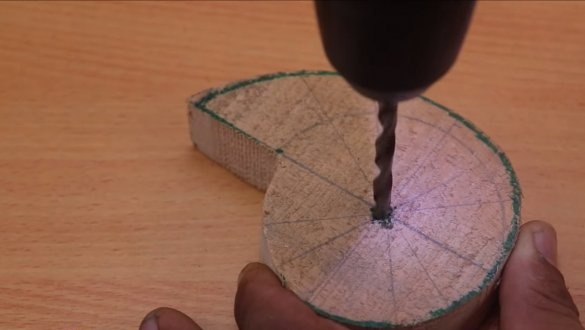

Step Two Eccentric

Let's make an eccentric, it is he who will raise the hammer above the anvil. The author made this detail from a thick board. First, we mark everything with a compass and a ruler, and then proceed to cutting. The author cut the part using an electric jigsaw. We give the product a finished look with sandpaper. In the center you need to drill a hole for the bolt. The bolt should be tightly wrapped in a tree, and it is also advisable to secure it with nuts.

We also make a rack on which we fix the axis. It is best that the axis rotates on a small bearing, the service life and performance will be much higher.

Step Three Screwdriver pad

We will make and install the platform on which we will install the screwdriver. It is important to correctly calculate the height so that the drill chuck is at the same level with the axis of the eccentric. The author has made a special recess in the area where the body of the screwdriver will go. It can be made a chisel and so on.

Step Four Anvil

Let's make an anvil, for it we need a bigger hammer. We fix the metal part of the hammer to the base using the bracket from the board.

Step Five Elastic

We install an elastic band on the machine, which will “beat” on the anvil. The author used a silicone automobile hose as such a rubber band. We fix it with self-tapping screws with washers.

In the handle of the hammer we wrap several screws, they will allow us to fix the gum and change its stiffness.

Step Six We install a screwdriver and test homemade

We install, clamp the eccentric axis in the chuck of a screwdriver. The author himself screwdriver secures with the help of the spirit of metal clamps.

We turn on the screwdriver and test the gun. The author did pretty well, although the hammer has a small weight, but the power of the machine is quite enough. Thus, using the mind, we facilitated physical labor, which is already excellent.

I hope you liked the homemade work, and you learned something new for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share with us your ideas and homemade products.