The master called his lantern "monster." The lantern has a 100 W LED and produces a luminous flux of 10,000 lumens.

Let's see the difference between the light emitted by the headlights of a car (high beam) and a lamp. The first photo of the angle auto, second photo is a lantern.

Two more examples.

To make a powerful LED flashlight, the master used the following

Tools and materials:

-100 W LED;

-Lens -2 pcs;

- PVC pipe;

-Cooler;

-Fasteners;

-Drilling machine;

- thermal paste;

-Radiator;

-Reflector;

- Electric jigsaw;

-Drill;

-Fan;

-Grid;

-Temperature sensor;

-A pen;

-Screwdriver;

- Battery pack lithium-ion 12 V 12000 mAh;

-Volt / Amp indicator;

-Increasing stabilizer;

-Switch;

-Tumbler;

-Fuse;

-Charge indicator;

-Wire;

- clamps;

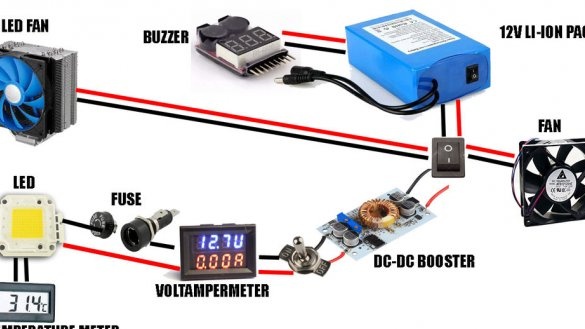

Step One: Scheme

The electric installation of the lantern is carried out according to the scheme below.

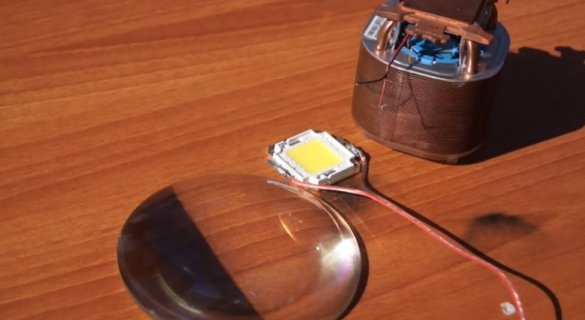

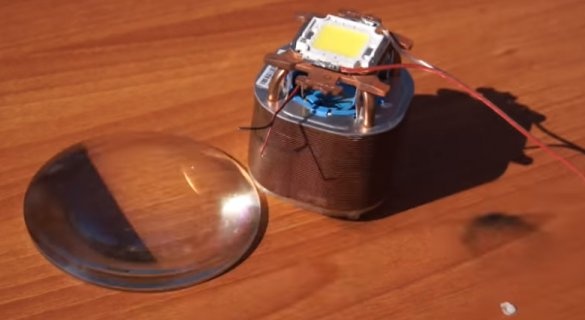

Step Two: Lens

Two lenses are used in the flashlight, one master acquired with an LED and a reflector, the second from an old enlarger. The lantern body is a sewer pipe. The master installs a lens from the enlarger into the coupler.

Step Three: LED

Drill mounting holes and screw the radiator to the cooler.

Applies thermal grease to the radiator and fixes the LED. Then installs a reflector and a lens.

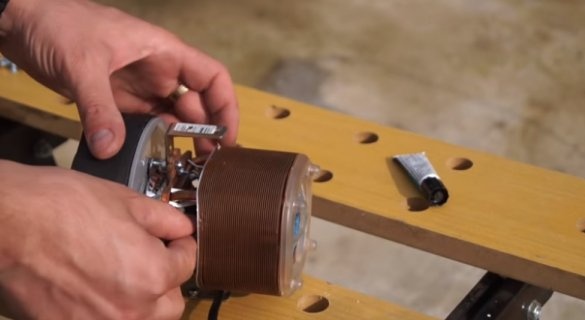

Step Four: Case

Cuts off a portion of the pipe. Cut holes in the pipe for appliances. Drills vents. The clutch makes a transverse cut to adjust the position of the lens. Cuts a window in the stub. Fastens the mesh.

Step Five: Build

Sets the LED with a cooler, indicators, buttons.

Installs the battery and fan in the back.

Secures the back cover.

The lantern is ready.

A few more examples of his work.

The whole process of assembling a monster flashlight can be seen in the video.