An unusual four-lamp desk lamp was made by the Master as a gift to relatives. A stand is mounted on a thick acrylic base. At the top of the rack are four levers with lamps at the ends. The levers can be raised and lowered independently of each other.

Tools and materials:

For the foundation

-Transparent acrylic block 200 mm X 200 mm X 50 mm;

- Cutting board 200 mm X 200 mm X 50 mm;

- Aluminum sheet 170 mm X 170 mm X 5 mm;

-Junction box with terminal block;

-Wire with plug and switch;

-4 pcs felt pads;

For rack

-2 pieces of a piece of beech 50 mm X 50 mm X 300 mm;

-2 pcs of a piece of cherry 50 mm X 50 mm X 300 mm

For the top

- Walnut block 110 mm X 110 mm X 35 mm;

-8 pcs of squares of black acrylic 20 mm X 20 mm X 1 mm;

-4 pcs 12 mm X 110 mm chrome-plated copper tube;

-4 pcs 12 mm x 25 mm chrome-plated copper tube;

-4 pcs 35 mm X 35 mm X 40 mm transparent acrylic;

-4 LED corn bulbs;

General

-Wood;

-Fasteners;

Epoxy resin;

-The wire;

-Pencil;

-Rule;

-Knife;

-Band-saw;

-Drill;

-Laser cutter;

-Clips and vise;

- Forstner drill;

-Sandpaper;

-Metal wool;

- Brasso polish;

-Gloves;

- Danish oil;

-Crosshead screwdriver;

-Pliers;

-Multimeter;

-Nippers;

-Lathe;

-Glue gun;

-Insulation tape;

-Pipe cutter;

Milling cutter;

Step One: Layout

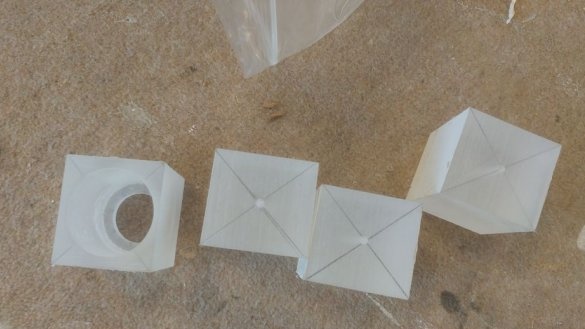

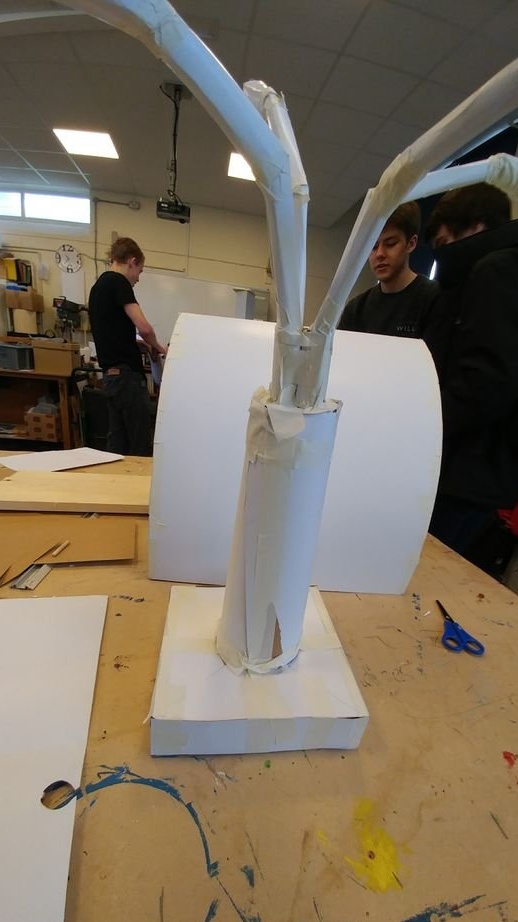

First, the master made a sketch of the lamp and its layout from paper.

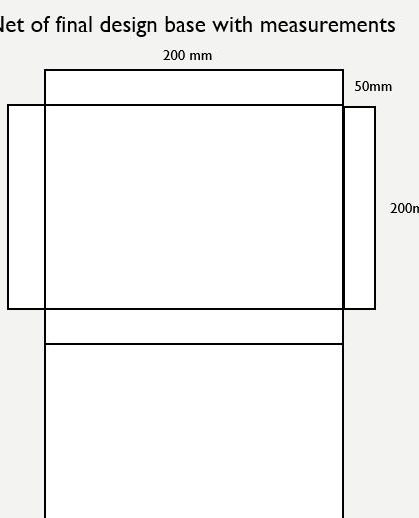

Step Two: Foundation

The base is made of two blocks. One block is acrylic, the second is wooden. Blocks are cut at an angle of 45 degrees. Then the master connected the blocks and temporarily fixed with tape. Clamping the block in the clamp, the master drilled a central hole for the wires, and four holes for mounting the rack. Bottom of the block carved a niche for the junction box. He secured the box in a niche by extending the wire into the channel. Screwed the bottom of the aluminum plate. Glued to the gasket plate.

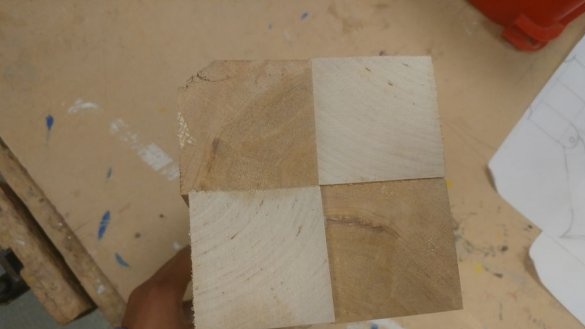

Step Three: Stand

The base is made of four bars of wood of different species, namely beech and cherry. Trims the bars to size, rounds off. Then glues and clamps with clamps. After the glue dries, the master cuts off the corners of the square, making it an octahedron.Then it processes the workpiece on a lathe. Drills a hole in the center for the wire and at the edges for fastening. Grinds and puts Danish oil on a surface. Pulls a wire into the channel and secures the rack on the base.

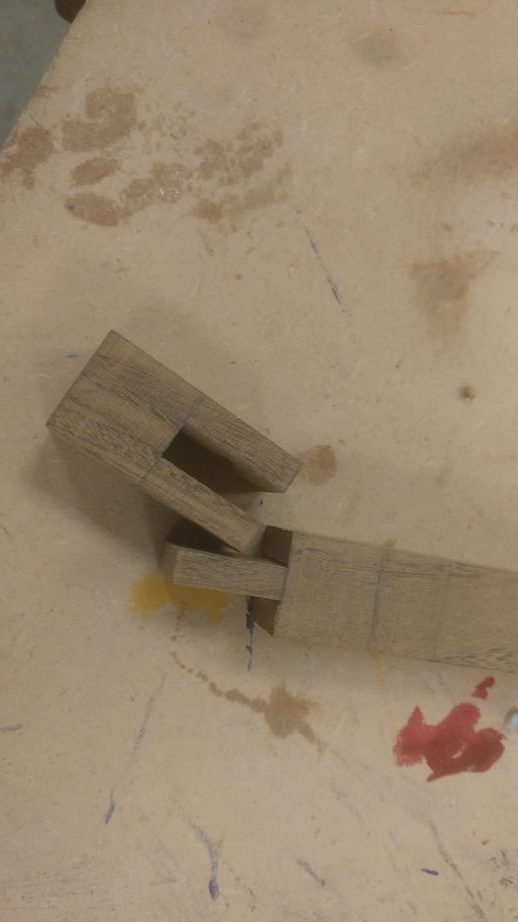

Step Four: Top

Now you need to make the upper part. First, the master made of wood "spike connection in the eye." The reverse sides of the joints are made in the form of a cube. A hole was drilled from the end of the cube along the diameter of the tube. So four connections are needed. I drilled holes in the side surfaces of the connection. Then it remains to polish the parts, cover with oil and connecting to install a bolt with a wing nut in the hole.

On both sides, tubes are inserted into the connection block. The master cuts the tubes to size and inserts into the holes in the blocks, after gluing black acrylic to each side of the block with a hole in the center.

He pulls wires into the tubes and fastens the short tubes to the rack. On long sections of tubes, it fixes a plafond of acrylic blocks, installs and connects a cartridge, installs a light bulb.

The reading lamp is ready.