In this article, the author of the YouTube channel "AKA KASYAN" will tell you how to use a halogen car lamp for soldering electronic components.

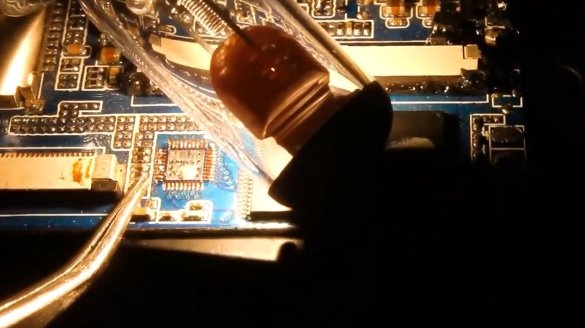

For example, you need to solder a microcircuit or a complex radio part with a heat-absorbing board.

Of course, you can try to do this with an ordinary soldering iron. But what to do in a situation where the housing of the chip deprives you of direct access to its conclusions?

In such situations, it would be logical to use a hot air soldering station, or rather a soldering iron.

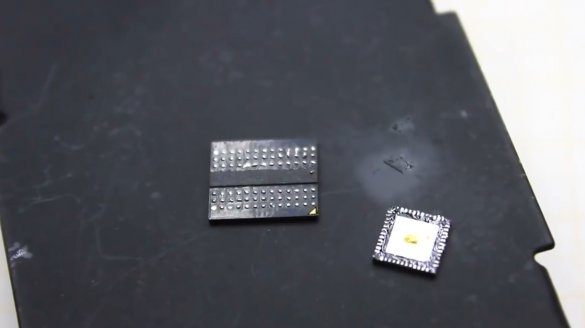

Materials

- Halogen lamp from a car headlight 60 or 100 watts

- Waste board with electronic components for testing.

Instruments, used by the author.

- tweezers

- Car battery or laboratory power supply.

- A multimeter with a thermometer.

Manufacturing process.

But what if you do not have such a station? In fact, any microcircuit from any printed circuit board can be dismantled in one very simple way and for this you literally do not need anything except a regular halogen lamp from a car

The advice is not a call for the widespread use of the proposed methodology, but the method deserves attention.

It all started with the author visiting with a friend who is also interested in electronics, and at that time he was repairing the computer motherboard, on which power field keys for power were burned. But, unfortunately, there was no soldering hair dryer for replacing keys at hand.

It is extremely difficult to dismantle such elements with a conventional soldering iron due to the heat capacity of the board and refractory solder, which components are soldered.

Without hesitation, we decided to try out the method of dismantling SMD components, which was tested by the author in the recent 2014.

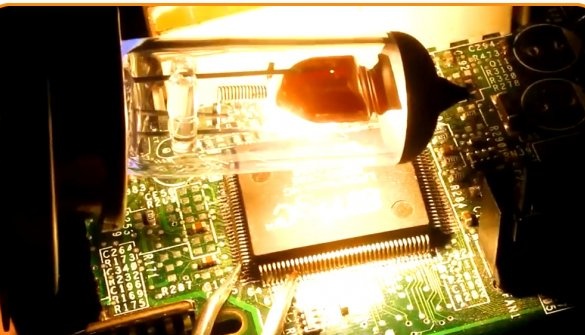

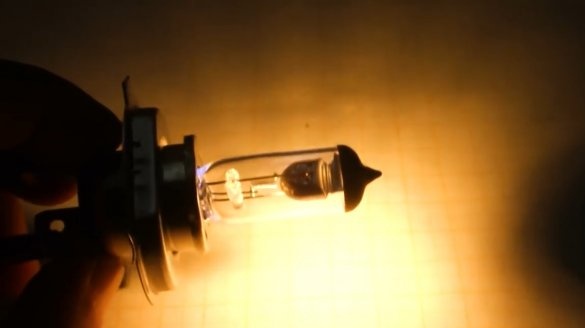

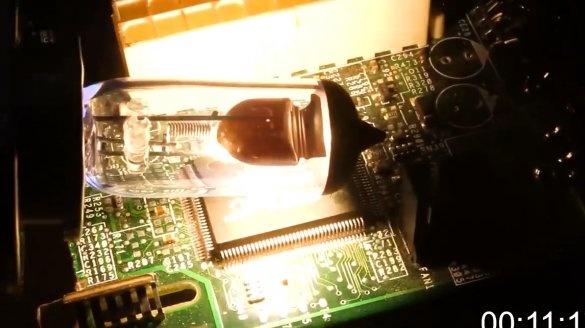

To carry out the dismantling operation, and then the subsequent installation, we need the most ordinary halogen lamp from the headlights of a regular car.

A lamp power of 60 watts is enough with the head, although 100 watts is possible. Any incandescent lamps, including halogen ones, are more not a source of light, but a source of heat.

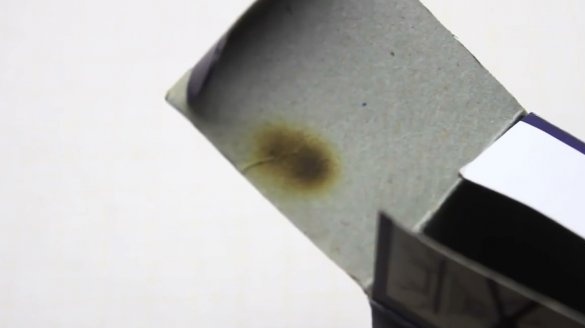

Since the filament, in addition to visible light, emits in the infrared, and this is the most that neither is heat. This is how paper is charred in just a few seconds of exposure.

Halogen headlight bulbs have two filaments. One of them is even equipped with its own reflector, which is very helpful here.

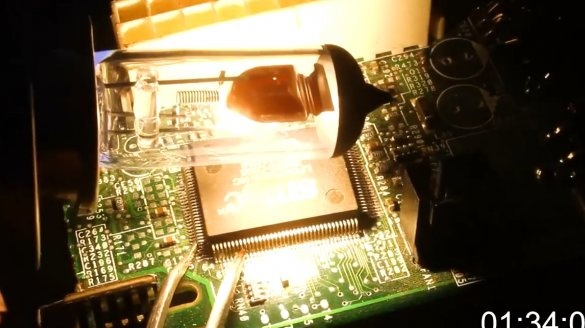

By directing the luminous flux, and hence the thermal radiation to a specific section of the printed circuit board, in just a few seconds the solder will heat up to the melting temperature.

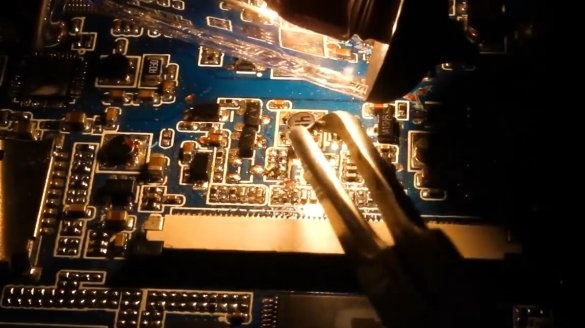

Then the component can be dismantled. Naturally, the heating time depends on the size of the component itself, the melting temperature of the solder, and on the heat capacity of the printed circuit board.

In the same way, modern infrared soldering stations are heated, but the latter, in addition to the upper heating, also has a lower one, plus electronics that monitor various parameters.

The power source for our "high-tech" soldering station can be a car battery.

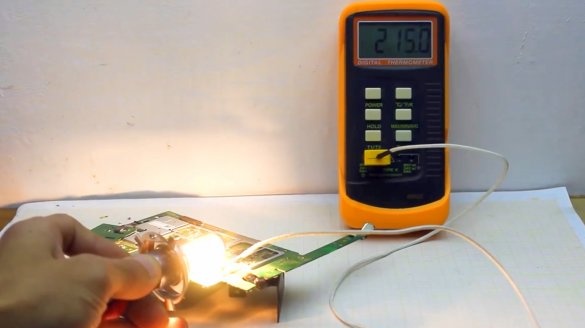

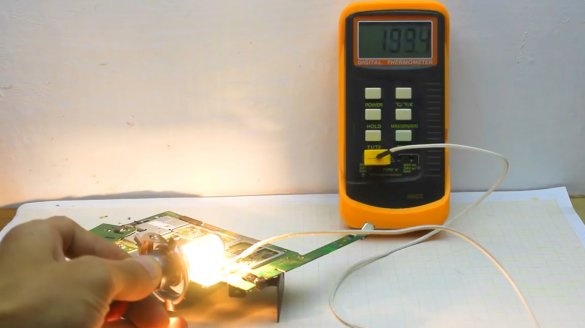

The author recommends raising the supply voltage to 16 volts. It is convenient to power a halogen lamp from an adjustable power supply.

By adjusting the voltage, we can change the heating temperature.

With tension - without fanaticism, otherwise the halogen will quickly be covered with a copper basin.

The author also strongly advises controlling the temperature on the board in a contact way so as not to overheat the board and soldered components.

The lamp will remain very hot for a long time after turning off the power, so be careful and be careful. Work better with gloves on.

The master also strongly recommends wearing sunglasses during operation, since halogens emit quite bright light, the direct effect of which is harmful to the eyes.

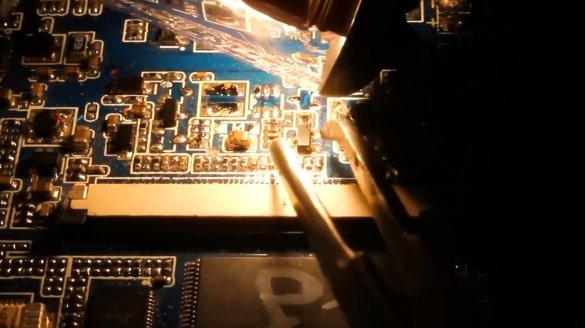

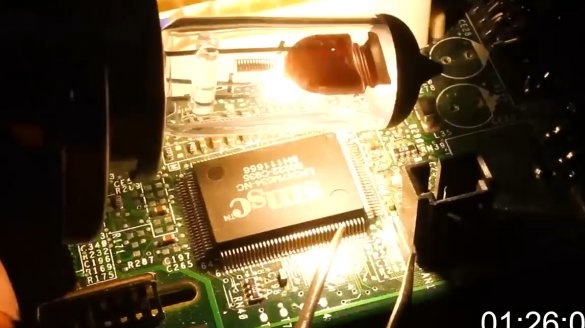

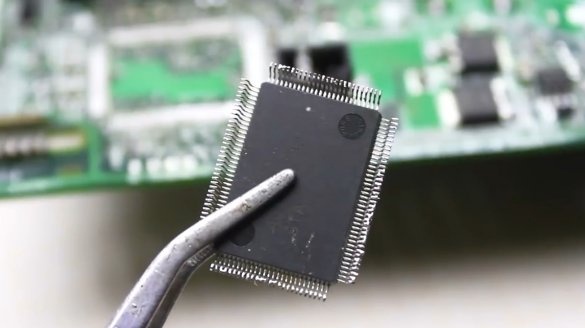

As a final test, let's try to unsolder a rather massive chip with a large number of conclusions.

It is very, very problematic to dismantle such a chip with an ordinary soldering iron without damaging the tracks on the board.

And using this method, the author coped with the task in one and a half minutes, while the tracks on the board remained safe and sound.

Thanks to the author for the original technology of soldering complex radio components in a very simple and affordable way!

Good luck to everyone, good mood, and interesting ideas!