When cutting holes in a metal sheet with a grinder, the edges of the cut are sharp and often not very even. Smoothing, leveling and grinding them by hand is a long and tedious task, and no mechanized tool for such work has yet been invented.

The edge processing can be significantly accelerated if you use a drill with a special nozzle made of a waste piece of a hexagonal steel bar 10-15 cm long and the larger the diameter, the better. Assembled it device looks like that:

To make the device you need:

1. the bar itself;

2. washer, sleeve and clamping nut from an old grinder, with which grinding or cutting discs are attached to the angle grinder;

3. Several abrasive grinding wheels with a diameter of approximately 8 mm larger than the diameter of the clamping nut. When working with metal grinder such circles are usually very many.

In order to make a nozzle, one end of the rod is processed so that it can be clamped in the drill chuck, and the diameter of the second is adjusted to the diameter of the hole of the abrasive wheels and the thread for the clamping nut is cut on it.

On the surface of the cross-section of the bar where the thread begins, the grinder gently grinds the place where the washer taken from the old grinder will be pressed. As shown in the photo.

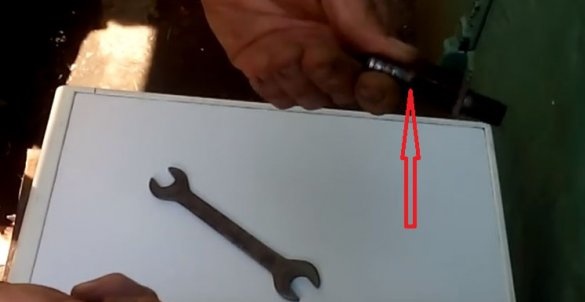

After that, a washer is put on the rod from the thread side, then, on top of each other, are several sharpened old abrasive wheels, which are fixed with a sleeve and a clamping nut. Do this with the help of a wrench and a special angle grinder included in the kit.

To process the edges of the holes in the metal, the device is clamped in the drill chuck and, turning it on, it is easy and fast enough to grind the metal edges with the ribs of the paired abrasive wheels clamped in the nozzle. At the same time, you can not only rid the edges of the “cutting” ability, but, if necessary, make them perfectly even.

Of course, this idea of processing the sharp edges of cut sheet metal can be realized without making such a device by simply removing the spindle from the grinder and fixing the abrasive wheels on it. But many of them at the same time will not fit on it, and the nozzle will turn out to be short and relatively inconvenient to work with.

Video explaining the manufacture of devices for processing sharp edges of a metal using a drill: