When buying a power tool, we hope for its reliable and long-term work. Power tools such as electric drills, a screwdriver and a rotary hammer are equipped with speed controllers for the electric motor, and these are relatively expensive tools. But very often there is no money for an expensive purchase and we buy cheap models. Inexpensive models of grinders do not have speed control knobs - only the power button. Because of this, grinders quickly become malfunctioning, because with a sharp start of a multi-turn collector electric motor, gearboxes often break down and the anchor winding burns out.

I collected in home conditions, the protective module of the collector motor eliminates such malfunctions and protects against the harmful effects:

A large load on the axis of the gearbox leads to an inertial jump, which contributes to the loss of power from the hands.

High torque during the start-up period accelerates the wear of the gears of the gearbox.

Destruction of a cutting wheel at overloads.

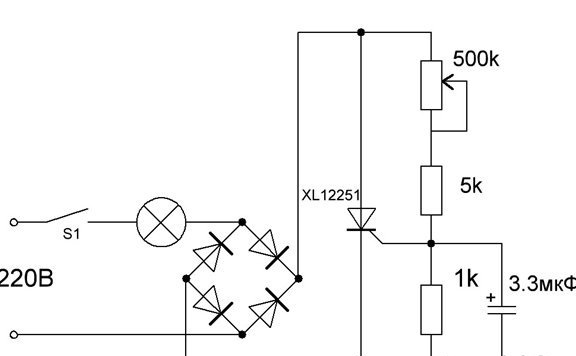

The protection module consists of two electronic devices soft starter for angle grinders, circular up to 2.5 kW and thyristor speed controller of the collector motor.

I wrote out the first block by cash on delivery in the department of the "Switches and Buttons" catalog, and the second one I made according to this scheme:

Only the thyristor was replaced by a more powerful, KU-202 n

The regulator has become able to withstand loads of more than two kilowatts.

I used the board from the burned-out regulator of the Chinese table lamp.

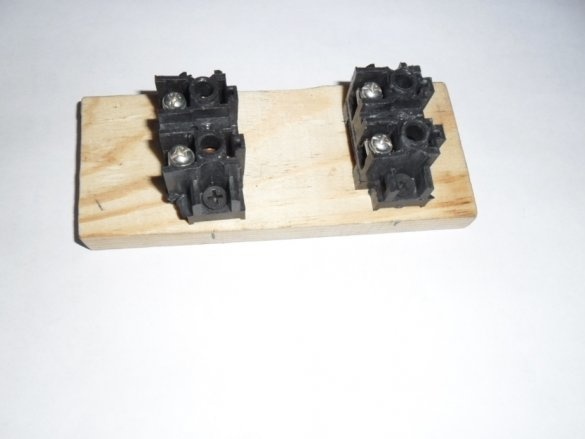

To complete the construction, I used two electrical outlets and a suitable plaque under the base.

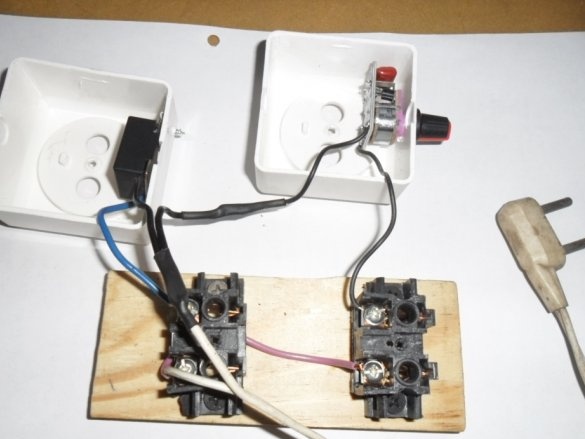

The protective module is placed in the housings of these outlets.

Sockets with screws fixed on a wooden base.

Installation of components according to the photograph

Made stranded wire segments

Soldering, it is more reliable than bolted terminal blocks. I collected everything

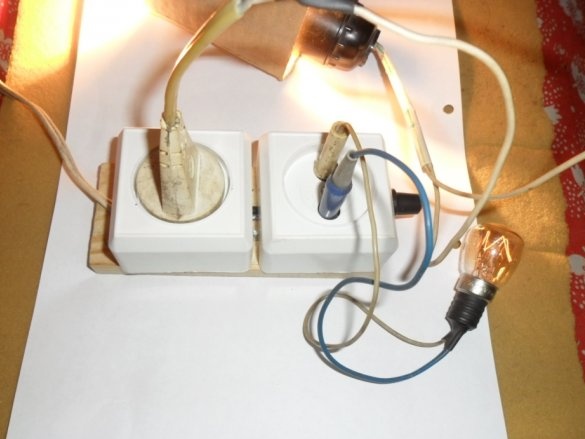

Tested

I was more than satisfied with the results.