Some of the Hall sensors used in computer fans are able to determine not only the presence, magnitude and polarity of the magnetic field. As, for example, a four-pin type sensor AH276 with built-in drivers for two motor windings. The times when there were discrete transistors in such fans after a three-pin sensor have passed. The author of Instructables under the nickname TheRadMan came up with how to make a magnetic field polarity determiner from a board from a fan with this sensor. He took the idea itself and.

The developer soberly assesses whether it is possible to reanimate the fan. It is usually sufficient to remove dust and grease the bearing. If nothing helps already, it's time to do what is shown on the KDPV. The master receives a lot of useful things in the household: a bearing, magnets, a winding wire, and a board with a sensor.

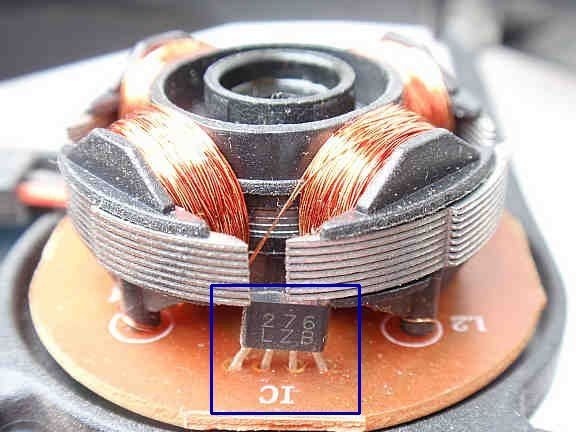

And here she is - the board with the motor stator:

Which the master solders and places next to:

He puts off the stator until the moment when he needs a winding wire for some solenoid, transformer, magnetic antenna, and what else happens there, and with the board he does this:

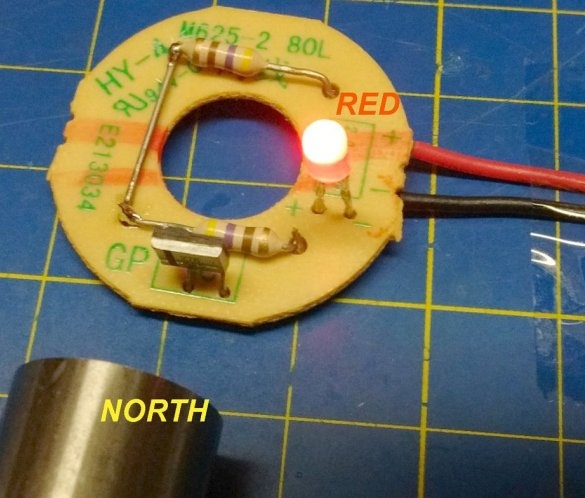

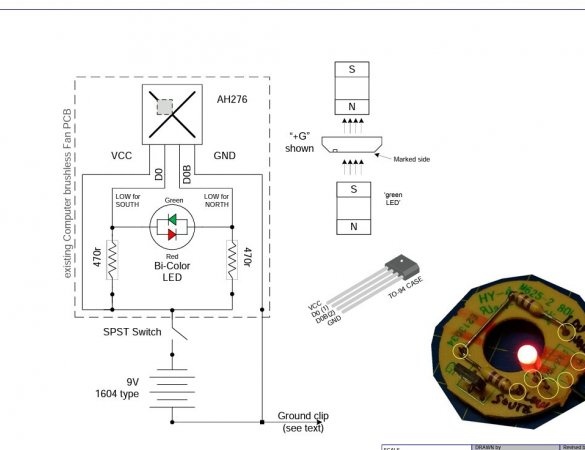

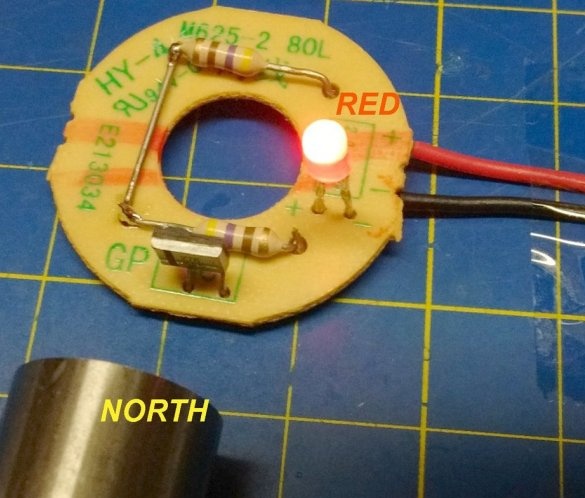

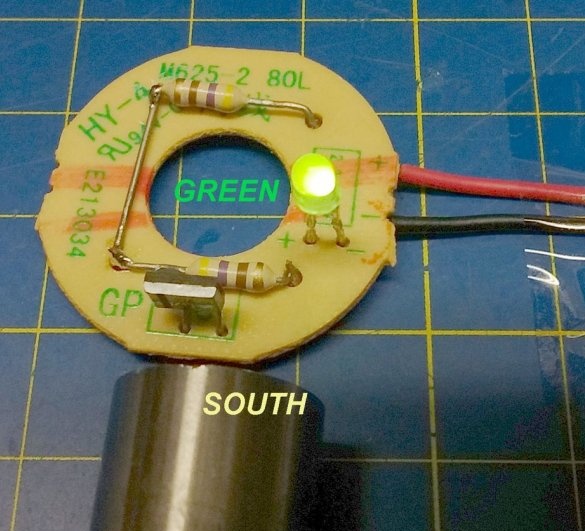

In other words, it adds two resistors and a two-output two-color LED according to the following scheme:

If you do not have such an LED, the first of the links given at the beginning of the instruction shows a diagram of a variant with two ordinary LEDs. Or you can, without changing the scheme proposed by TheRadMan, connect two ordinary LEDs in counter-parallel. With a working sensor, all options will work. Note that in the absence of a field, one of the LEDs (or one of the crystals of the two-color LED) is still lit, so you need a switch. The master assembled three devices, in one of which he used a “Krona” battery to power, and in two more - two CR2032 elements connected in series. So the developer using a magnet with a known pole arrangement determines the color matching of the poles:

The device responds to the magnetic field of the windings of sufficiently large relays and contactors, making it possible to determine at the same time whether they are supplied with direct or alternating current.But to find out if the contact groups have worked (all of a sudden the mechanical part of the relay or coactor is faulty), using this identifier is impossible. He does not respond to the magnetic field of the windings of very low-power relays. But if the situation is noisy, and the relay is powerful and without an integrated LED (or a modular contactor without moving parts visible outside and a window with a lens) - it really helps.

Also homemade reacts to a fridge magnet, which is by no means neodymium. In terms of sensitivity, it is similar to the ExTECH MD10 device at a price of about $ 50.