Good day to all. In this article, the author of the channel. Show how to do do it yourself, such a nozzle for an engraver.

By this principle, you can do nozzles for electric drills.

You can certainly buy, but we all know that any consumables wear out pretty quickly, but they are not very cheap. And by the way, not everywhere you can buy them. And for this, I think many joiners, and various kinds of craftsmen will be interested in such homemade. Moreover, for its manufacture will not require anything special. All the necessary materials will be found in everyone who has at least once done something with their own hands. So, let's begin.

Materials: Glue second.

Sealant technical.

If not, I think you can replace it with a piece of a bicycle camera, rubber patches.

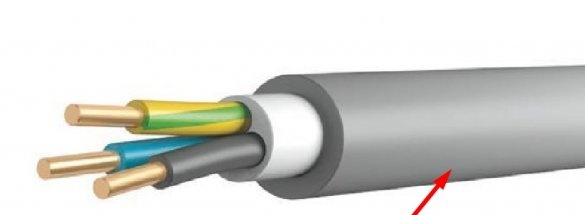

Or at worst use a piece of insulation from an old waste wire.

A piece of hardwood, the author is a beech.

Nails 80x3.0 mm.

A few wood chips.

And sandpaper of different grains.

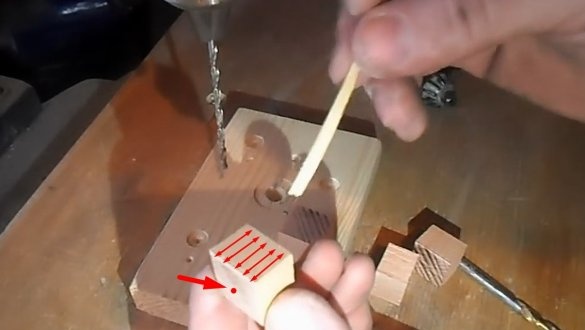

The author chopped a piece of wood into small squares.

Then he made a through hole in the center of these blanks, along the location of the wood fibers. The diameter of the hole is 3 mm.

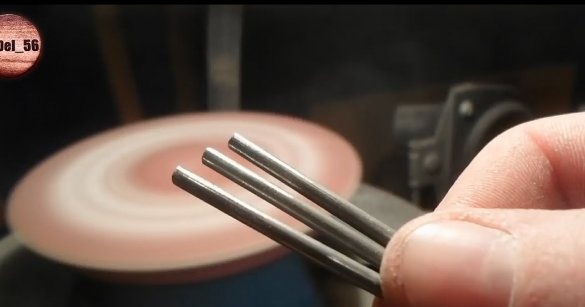

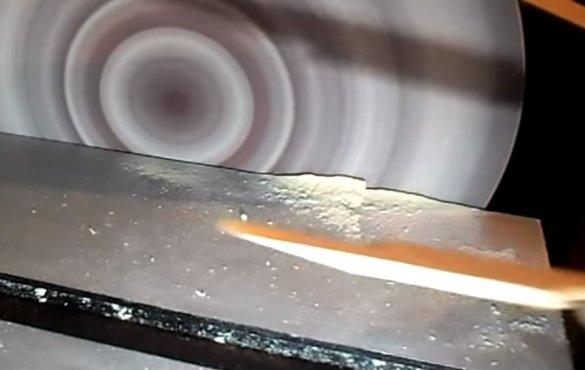

Then he will take the nails and clamp them in a vice, with the help of angle grinder he will remove sharp edges and hats.

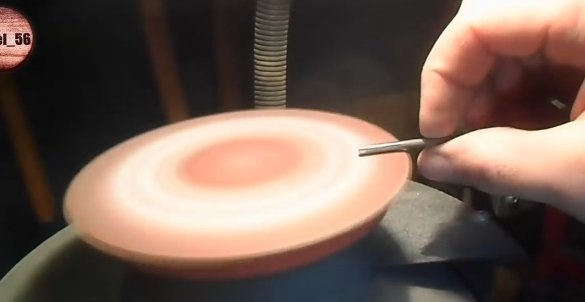

New nails are usually lubricated to prevent rust. Therefore, the author will polish them a little to remove the grease.

After these nails, the author glues them into wooden blanks.

Then these blanks, the author will give a cylindrical shape.

And after that he will not make a deep longitudinal cut.

Such blanks have turned out.

Then he will take measurements and cut a strip of sandpaper along the width of the workpiece.

Then measures the desired length.

And cuts off the excess.

Next, sets the edges of the sandpaper in the cut.

A wedge will be made of wood chips and set to cut.

Thus, the paper will be well fixed and will not fly off during operation.

Inserting a wedge, it simply breaks off the excess.

These are simple and not difficult to manufacture nozzles you can make yourself.

But the master decided to conduct an experiment. On one of the blanks, he pasted a piece of sealant.

After removed everything unnecessary.

And he did a bit of angle grinder, giving the workpiece the desired shape.

It turned out somehow.

After installing and fixing the sandpaper.

Now the test. Firm nozzle. Grit 120.

Conclusion: this homemade job does its job well.

Now test the nozzle with gasket. Granularity is also 120.

Conclusion: this nozzle proved to be even better than the previous one.

In the process of long work with nozzles on a solid basis, paper wear is faster.

The metal test also showed excellent results.

And that’s all for me. Thank you all and see you soon!