The master is an avid billiards player. To play the pool, he decided to make an exclusive cue using epoxy resin and wood chips. The cue consists of two main parts, a turnip and a shaft. Turnyak is the upper part of the cue, approximately to the middle. This is what the master will do.

Tools and materials:

-Wood Walnut;

Epoxy resin;

-Pigment;

-Plywood;

-Camera pressure;

-Drill;

-Lathe;

-Turning tool;

-Rubber plugs;

-Drills and swords;

-Polish;

-Rule;

-Pencil;

-A circular saw;

-Hammer;

-Ax;

-CA glue (super glue);

Step One: Chips

Using an ax and a hammer, the author splits walnut wood into wood chips.

Step Two: Fill

First, the master makes a rectangular box from the plywood along the length of the cue. In the center of the box is a wooden cue. Covers it from all sides with wood chips.

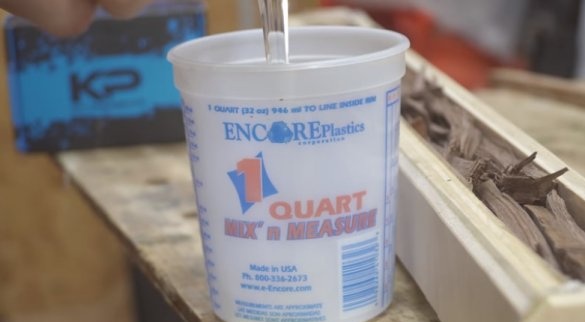

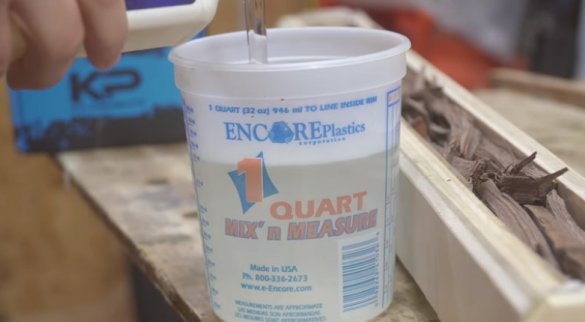

Knead epoxy. Adds pigment to the resin. Pours resin into the mold.

Step Three: Pressure Chamber

The mold does not fit into a standard chamber, so the master made another one from a PVC pipe. Places the mold in the chamber and pumps a pressure of 3 atm. In this state, the mold remains until the resin solidifies. What is it for? During the pouring process, a lot of air enters the workpiece together with the resin. Using pressure, air is removed from the resin.

Fourth step: removing the workpiece

After solidification, the master removes the mold from the chamber and breaks it freeing the workpiece.

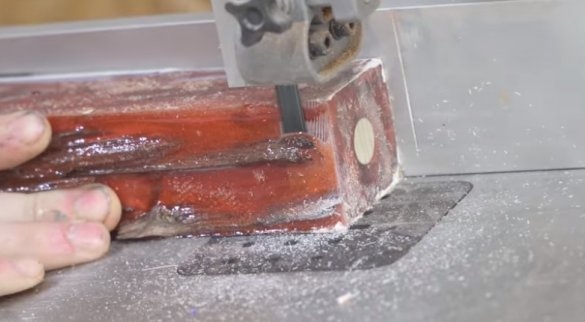

Step Five: Cropping

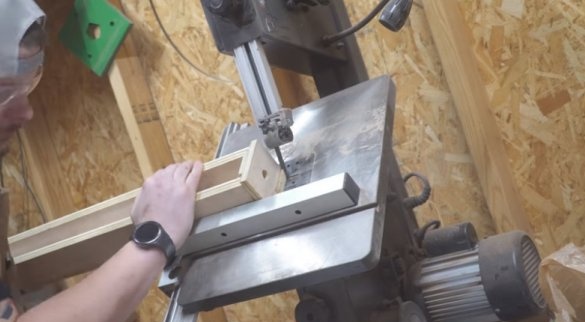

Trims the sides of the workpiece. Cuts it to the desired length. Marks the centers of the end faces of the workpiece.

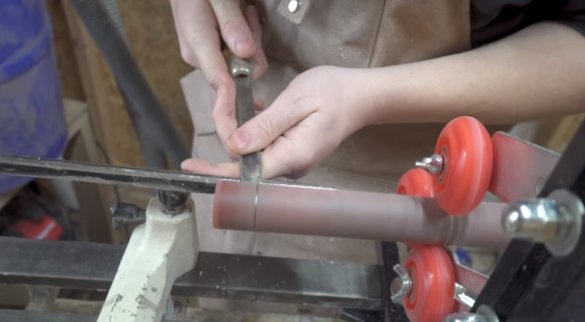

Step Six: Turning

Sets the workpiece in a lathe and grinds it. Sanding with sandpaper.

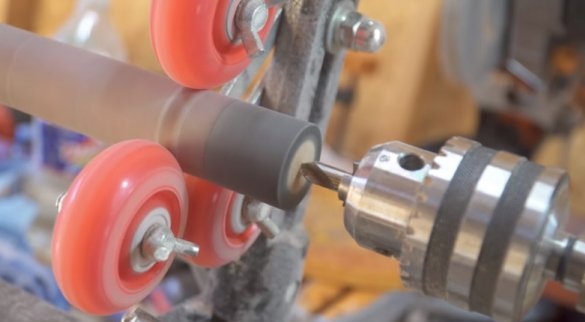

Seventh step: sleeve

Turns the seat for the sleeve. The sleeve will be installed in the butt part of the cue.

Glues the sleeve.

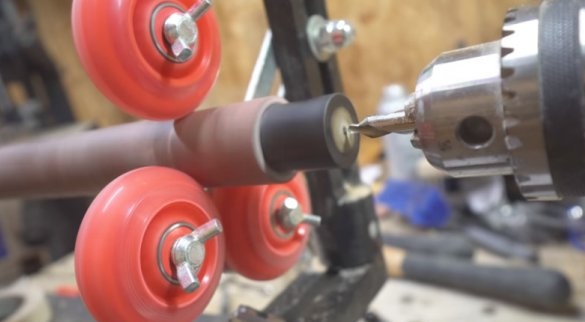

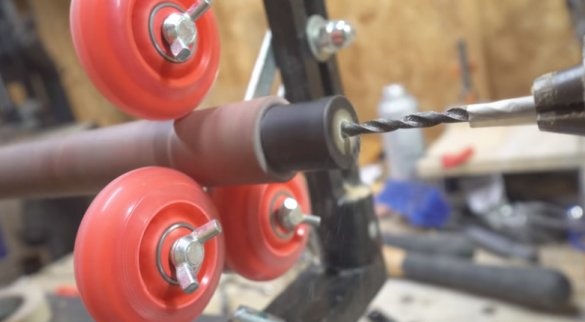

Step Eight: Pin

Now you need to install the connecting pin. Drills a hole in the center. Cuts the thread. Apply glue to the threaded part of the pin and screw the pin into the hole.

Step Nine: Tail Hub

The assembly process is similar to the previous one. Turns the end of the cue and sets the sleeve.

Drills a hole in the center.Installs the bumper.

Step Ten: Weight Adjustment

Now you need to grind the turnip, achieving the desired weight.

Step Eleven: Grinding, Polishing

The main operations are completed and the master proceeds to the final grinding.

Apply superglue to the surface. After drying, polishes.

At the last stage, it polishes.

Turnyak is ready. Now you need to attach the shaft and you can start the party.

Making a turnip can be seen in the video below.