In this article, the author of the YouTube channel “Your idea of TV” will tell you how he made his next Sharpener sharpener. The author made it from the Soviet diode poles KTs109A, the outer shell of which is a ceramic tube, with excellent quality!

But they work, as a rule, on weight - just hold it by one edge in their hands. But this is unsafe, and when editing a knife it is very easy to cut their hands.

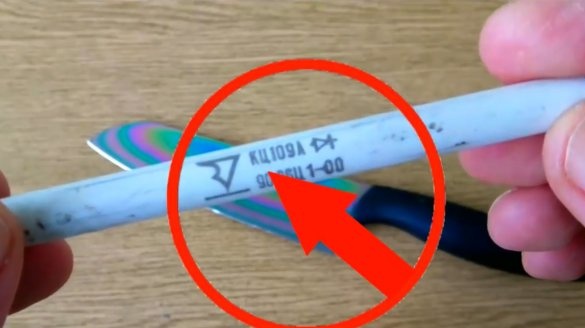

Rewrite its name - it will still be useful to you. And in order to make the sharpening safe for your fingers, the author decided to make a special stand similar to the well-known sharpener from Lansky.

Materials

- Cutting boards

- Diodes KTs109A

- Wood screw.

Instruments, used by the author.

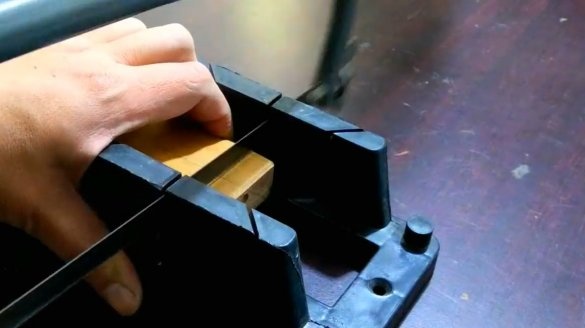

- Vise, clamps

- Grinding machine

- Hacksaw for wood

- Drill or screwdriver

- Drilling machine

- Nippers

- Sandpaper.

Manufacturing process.

For its manufacture, the master took a wooden block, for aesthetics it will need to be sanded, and all sharp edges should be removed. The author did this on a sandpaper drum.

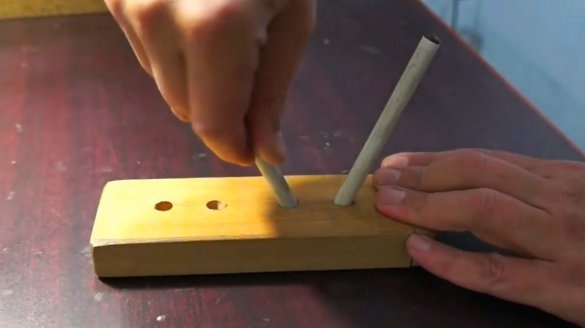

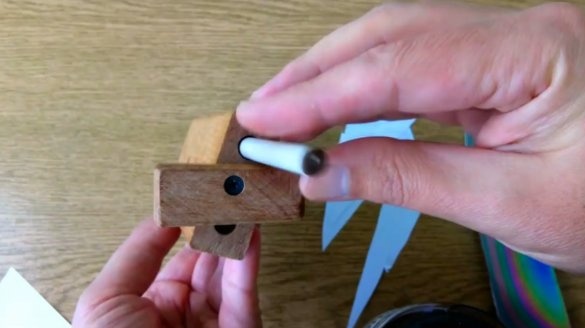

Further from the diodes you need to cut off the metal legs, and mark their location on the sharpener.

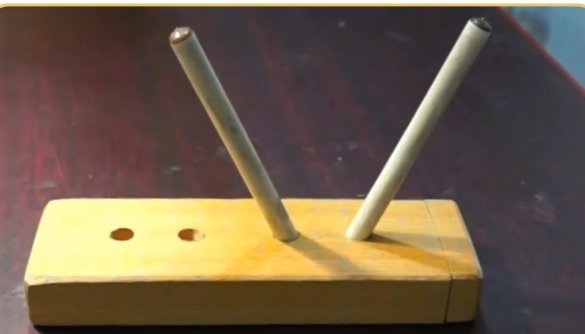

The author made two options - these are 18 and 25 degrees, and it’s convenient to store the diodes in the same box, making a special cap for the plug, and drilling a hole in the end with a diameter slightly larger than the diameter of the diodes.

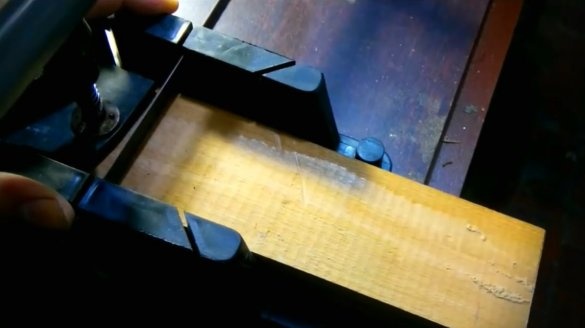

He did not find such a long drill on wood, and he drilled holes with a longer drill for metal, holding it by the shank with a clamp.

And now the most important thing - the hole for the diodes needs to be drilled strictly at a given angle, the author measured the angle with a smartphone and simply drilled it manually. At the drilling machine, the accuracy in degrees turned out to be quite acceptable, and the minutes in this case do not play a significant role.

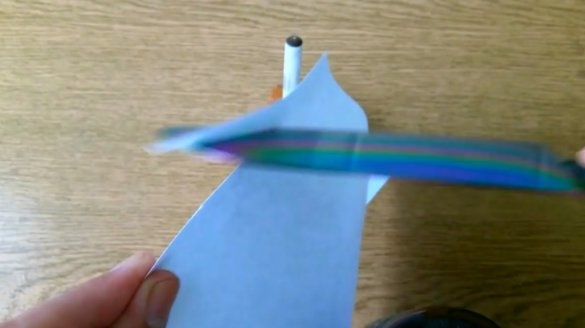

Notice how the grinder’s lid is arranged and the axis is shifted slightly up from the center, which allows you to get the tubes in turn - so there is less risk that they will both fly out and break.

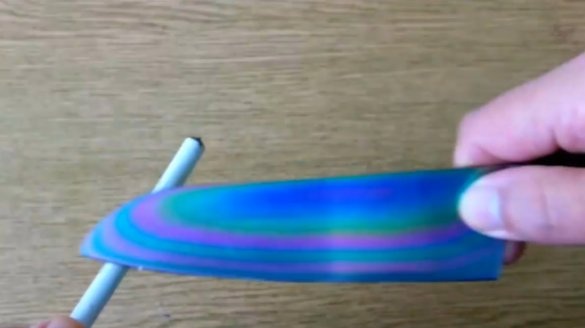

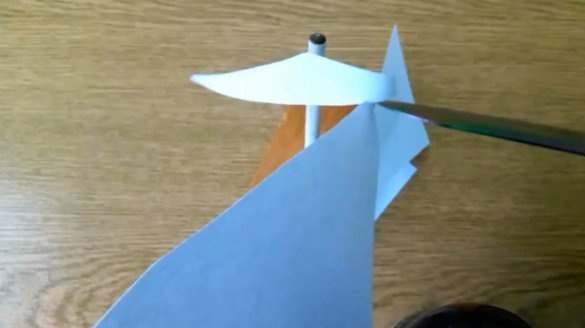

And now let's get down to testing, in the process of sharpening the knife must be kept strictly vertical, in this case the angle will remain constant. But you can choose which one is sharper or blunt for your knife. Such a sharpener is made very simple, and takes no more than an hour in time.

Ceramic removes metal quite aggressively, and soon black strips of metal appear on its surface. After sharpening, cleaning them is quite simple - you need to take sandpaper, not very large in abrasiveness, and in a minute your diodes will again become white and beautiful.

Of course, such a sharpener can be bought ready-made, but it is expensive, and the thing done do it yourself keeps the warmth of your hands and it is always pleasant to use it!

Thanks to the author for the interesting idea of a ceramic sharpener!

Good luck to everyone, good mood and original ideas!