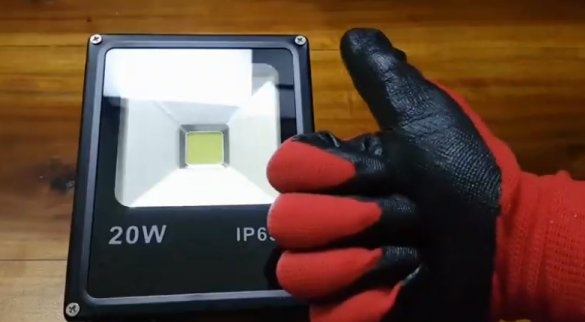

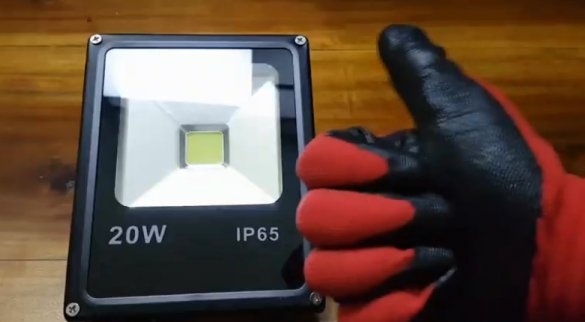

If the LED spotlight breaks down, many simply throw it away. The author of the video, which we will analyze here, decided to repair the spotlight, and moreover, to remake it powered by 12V with the ability to adjust brightness. For alteration, the master took a spotlight with a 20 W LED.

Tools and materials:

-Old spotlight;

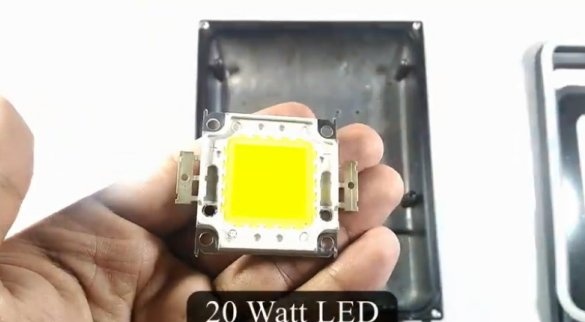

-LED 20W;

- thermal paste;

-Increasing XL6009 converter;

- Potentiometer 10 kOhm;

-Washer;

- Resistor 10 kOhm;

-Fasteners;

- 12V socket;

-Plug car;

-Wire;

-Screwdriver;

-Pliers;

-Soldering iron;

-Flux;

-Solder;

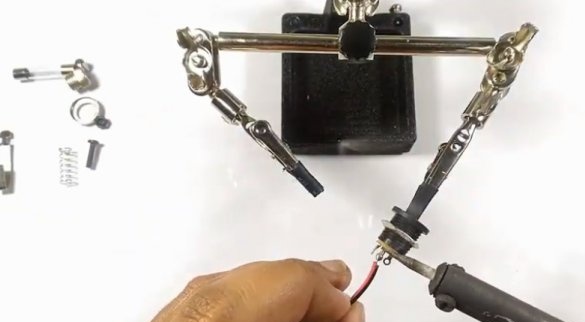

-Holder "Third Hand";

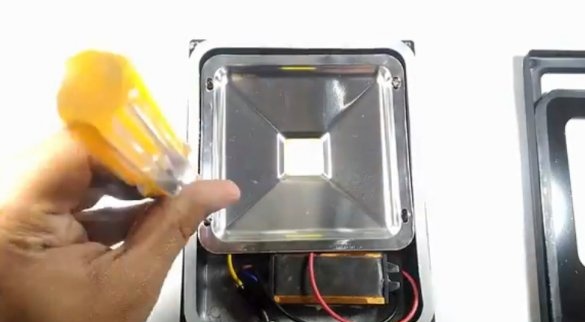

Step One: Disassembly

First, the master dismantled the LED housing, removed the glass, sealing rubber, and reflector.

Removes a driver.

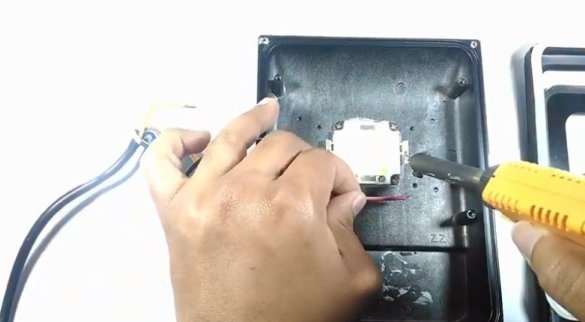

Then he checked whether the working LED. For a 20 W LED, the operating voltage is 30 V. The master supplies voltage to the LED, but it does not light up. The LED is not working and the master dismantles it.

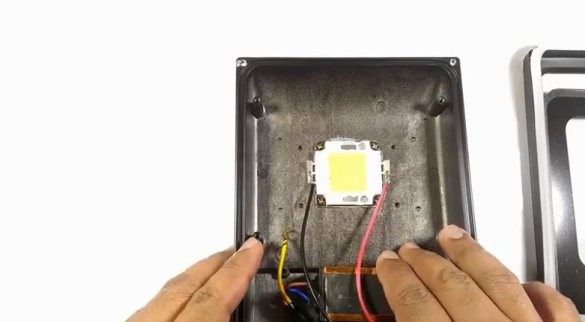

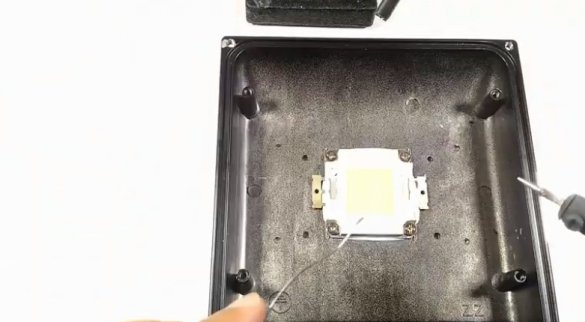

Step Two: Install the LED

Now the master installs a new LED in place of the non-working one. The diligence of the LED with the housing thoroughly cleans the old thermal paste and applies a new one. Screws on the LED.

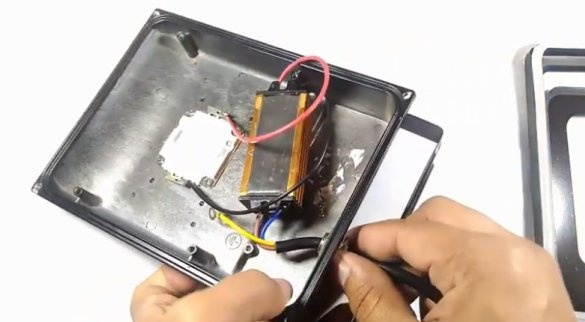

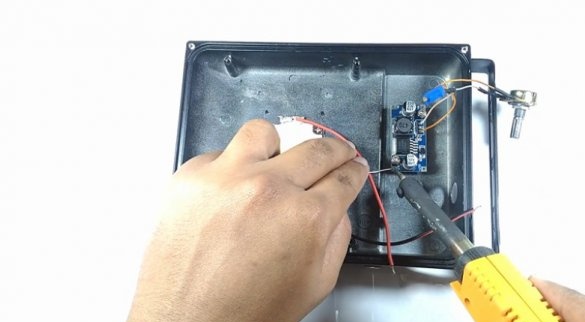

Step Three: Boost Converter

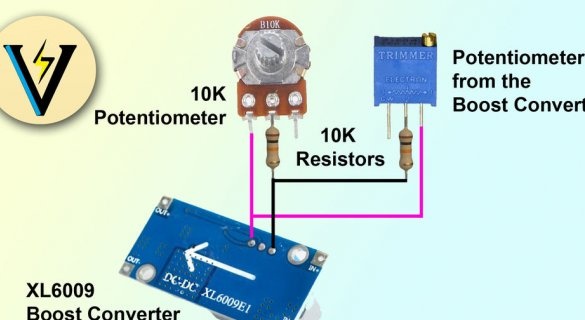

Now go to the wiring diagram.

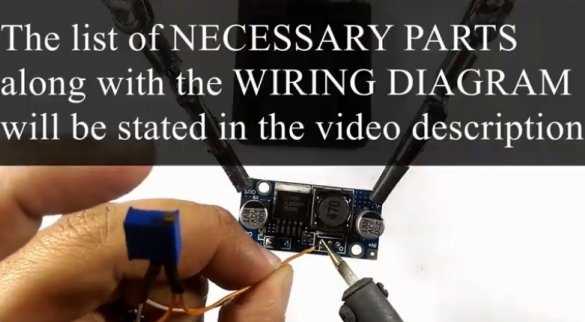

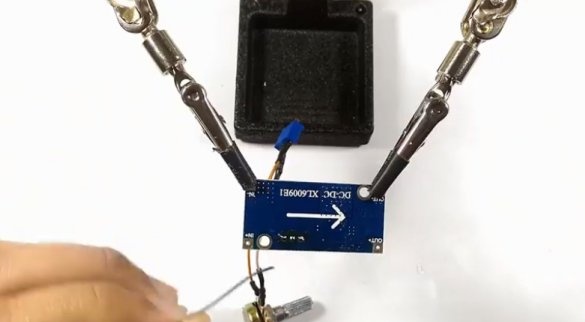

In the circuit, the master uses a DC-DC XL6009 step-up converter. The module has the following characteristics: input voltage 5 ... 35 V, output voltage 6 ... 45 V, maximum output current 4A. Four amperes with a margin for a 20 W LED.

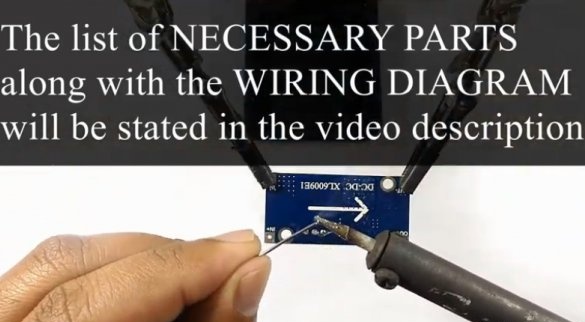

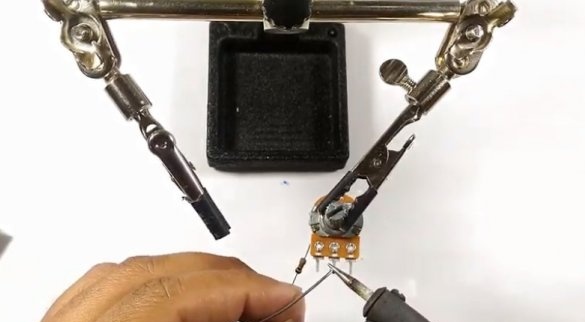

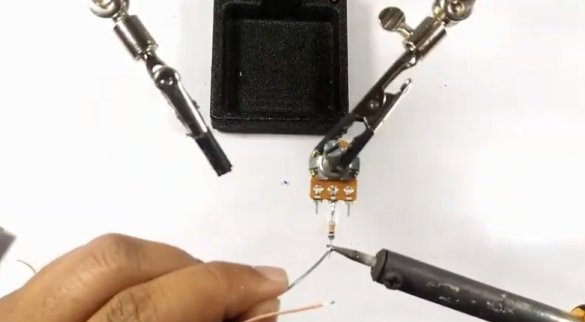

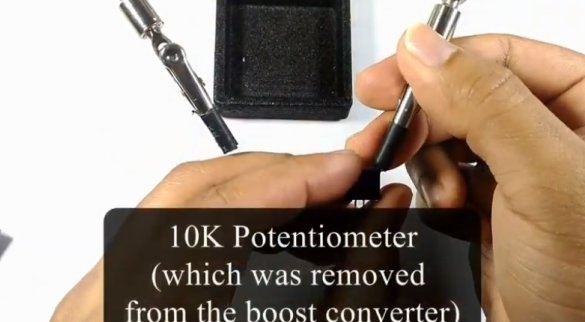

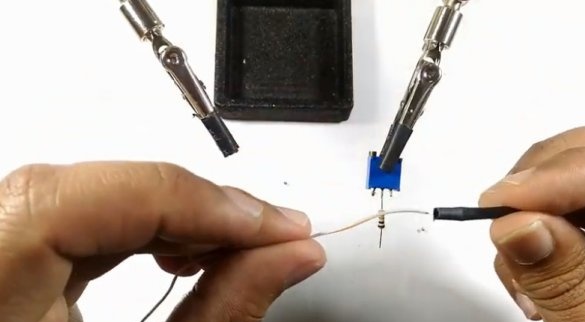

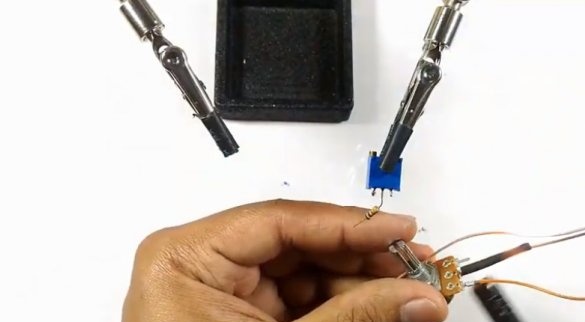

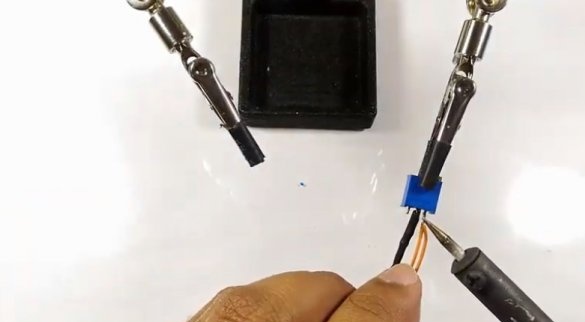

First, the master dropped a potentiometer from the converter board.

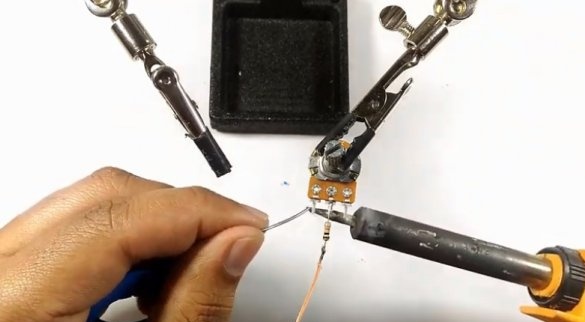

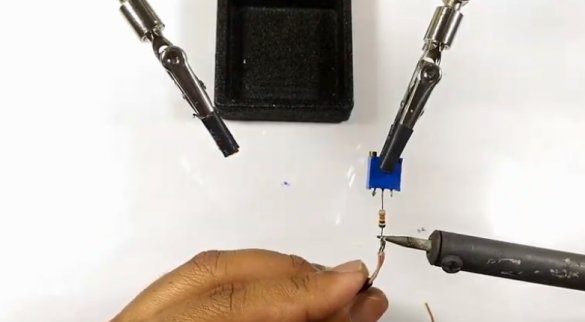

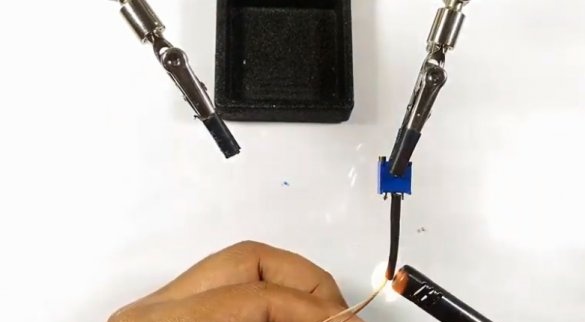

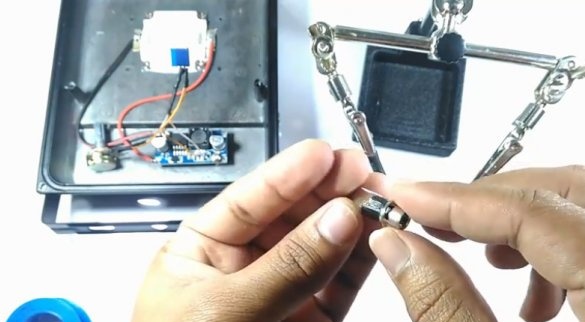

Further, everything is according to the scheme. The master solders 10 kΩ resistors to the middle pins of the potentiometers and connects them. Solders the wires to the extreme terminals of the potentiometers and also connects. Solder the wires to the terminals of the converter. The master puts on the heat-shrink tubing on the connections.

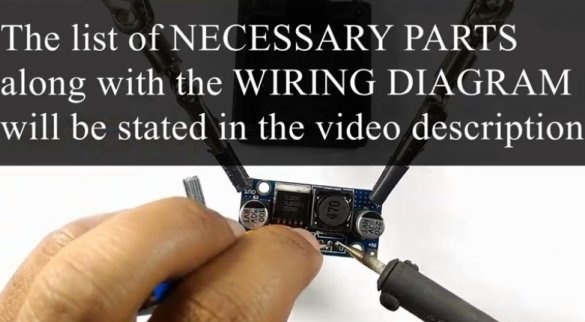

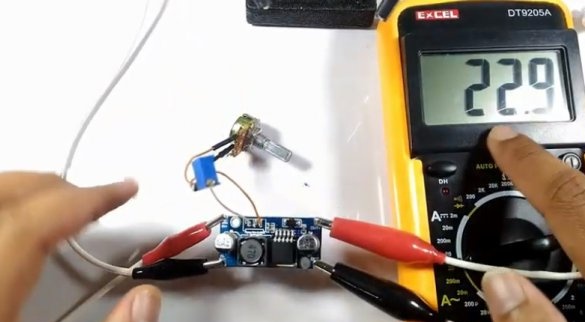

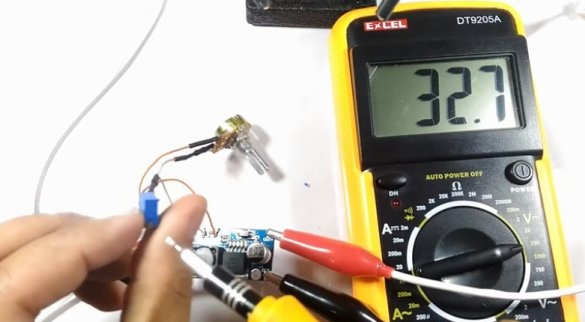

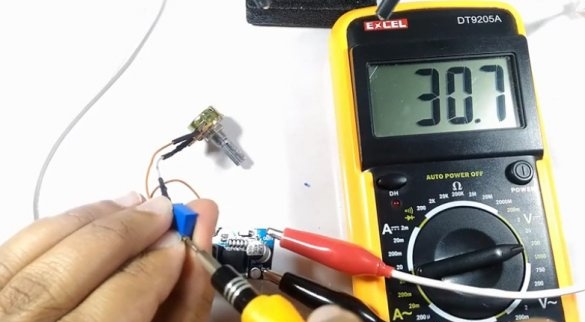

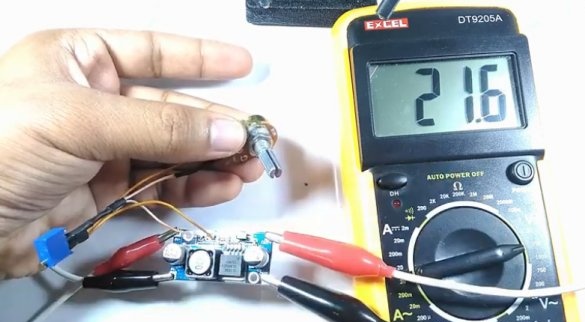

Step Four: Adjust

Now you need to adjust the maximum voltage.Connects the terminals of the multimeter to the output of the boost converter. It supplies 12 V. It sets a large (10 kOhm) to the far right position (completely unscrews). The adjusting screw on the small potentiometer (soldered from the board) sets the voltage to 30 V. This is the maximum voltage for a 20 W LED. Now, turning the handle of a large potentiometer, you can adjust the voltage without fear of disabling the LED.

Step Five: Build

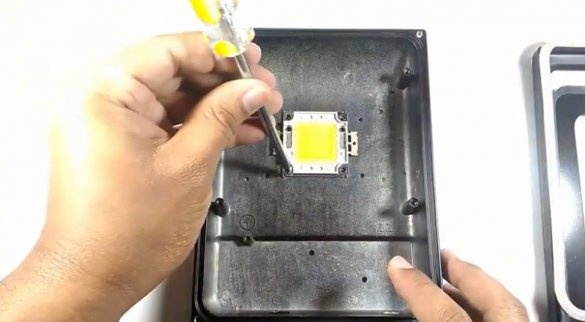

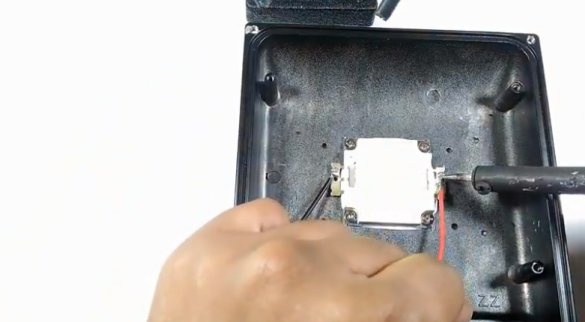

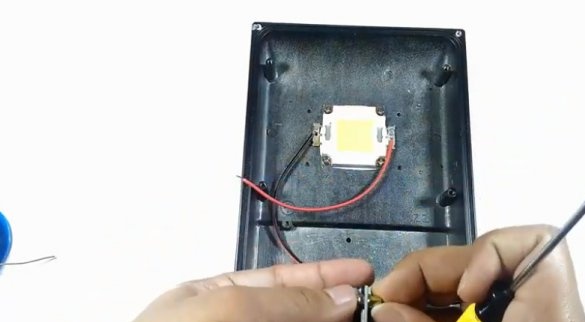

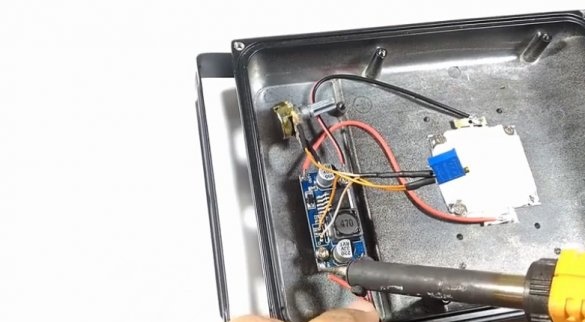

Solder wires to the LED.

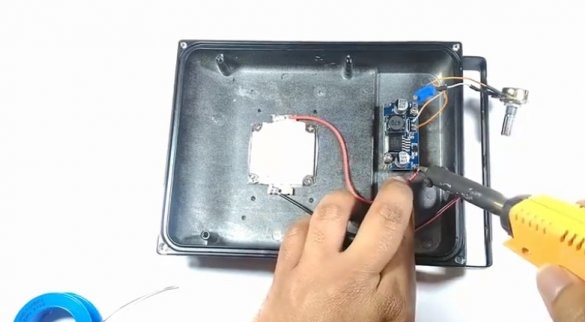

It fixes the boost converter and solders wires from the LED to its output.

Solder and install the connector.

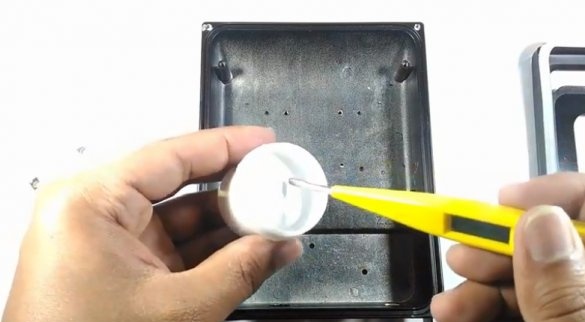

Installs a potentiometer in the hole in the housing.

Installs reflector, sealing gum, glass.

Puts on the handle of the potentiometer.

Step Six: Verification

The spotlight is ready and the master checks it,

first from the power supply

then from two batteries.

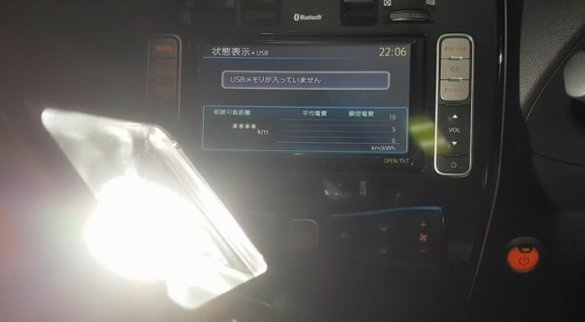

Spotlight works, works and brightness adjustment. Now you need to make the plug \ connector for the searchlight to work from the vehicle's on-board network.

Seventh step: connecting the spotlight to a car

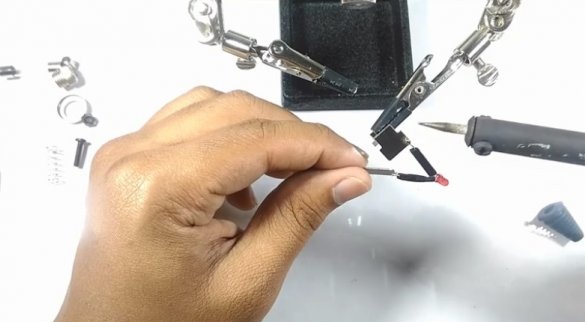

To connect to the on-board network, the master uses a redesigned auto-plug. Parses the plug. Solders parts.

Insulates with heat shrink tubing.

Solder the connector.

Assembles a plug.

Inserts a plug into the car socket. Connects plug and spotlight with wire.

Everything works.

In the video below you can see the entire process of manufacturing a searchlight.