In this article, the author of YouTube channel "Mistry MakeTool" will tell you

Materials

- Sheet steel

- Bolts, nuts M8

- Wooden block

- Stud or long bolt M10

- Steel round timber

- Masking tape

- Spray paint.

Instruments, used by the author.

- Bulgarian

- Drilling machine

- Orbital sander

- Petal stripping disc

- taps

- Hex and wrenches

- Cutting disc

- Hammer

- Ruler, marker, square, core

- Vise.

Manufacturing process.

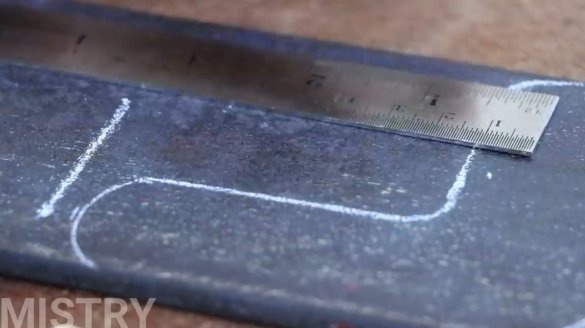

First of all, the master draws contours for the elements of the clamp frame, he will do two identical at once. When marking radius fillets, it is convenient to use some kind of cylindrical object.

He prudently drilled holes in the inner corners for easy handling. Cuts blanks along the contour with a grinder.

Then the resulting workpiece is clamped in a vice, changes the disc on the grinder on the grinder, and carefully processes the edges of the parts.

It connects the blanks with masking tape, marks the future holes with a core.

Now he drills all the necessary holes.

Starts assembling the power section of the frame using self-locking nuts.

So, the main part of the frame is ready, now you need to make bushings from steel round timber.

Marks the bushings and tries on a bolt.

Then grinds part of the thread on the bolt using an orbital sander.

Screws an elongated nut onto a bolt, marks the place for the swivel hole with a core, and drills it.

Makes central and transverse holes in the bushings.

Then cuts the thread in them with taps.

Screws the first sleeve onto the bolt, and puts the second onto the place where the thread is machined.

Now just rivets the protruding edge of the bolt with a hammer, this sleeve should rotate freely.

Installs the bushings in their place in the frame, fixes them with bolts.

Inserts the swivel into the clamping screw, the tool is almost ready.

Only clamping jaws are missing, of course, they can be made of metal and rubber. But the author will make them from a solid variety of wood. Tries on a bar and cuts four pieces.

Marks the center on the workpieces, and drills holes.

Then stains with black spray paint and leaves to dry.

The blanks are dry, sets them in a frame.

That's it, the clamps are ready to go.

The clamping force was very strong. You can safely process the workpiece.

Thanks to the author for the original idea of powerful clamps!

Good luck to everyone, good mood, and interesting ideas!