In this article, the author of the YouTube channel "Mistry MakeTool" will tell you how he made a reciprocating saw based on a screwdriver.

Materials

- Steel bar 10 mm thick

- Bearing with a central bore of 10 mm

- steel plate

- M6 bolts

- nails

- Cloth from a hacksaw

- Steel square.

Instruments, used by the author.

- Drilling machine

- Welding machine

- File, file

- Hammer

- Bulgarian, cutting and stripping flap discs

- Vise.

Manufacturing process.

So, the first thing the author puts on the bearing on a steel bar, marks the place of the file.

Then, holding the bar in a vise, he makes a marking file with a file. Next - two oblique saw cuts on both sides of the bar, already using a wide file.

Now the bearing is put on the bar, and in the slots made it rises already at an angle.

Then the author welds the central part of the bearing to the bar.

The following details the master makes two supports for the bar. He does it from a thick steel plate. Marks the center, core, and drill holes.

Now you need to make a bottom for fixtures, and drill four mounting holes in it.

After threading the bar into the side supports, the master tries on the cover, and marks the places of attachment to the supports.

Drills holes for bolts, cuts threads in them.

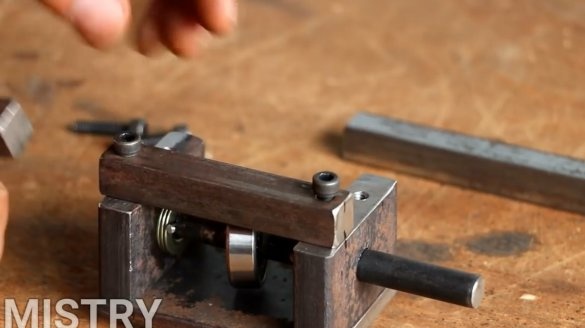

Now preassembles the structure.

And marks the places for drilling holes for the dowels on the shaft.

Drills two through holes in the bar.

Clogs in them a suitable diameter of cloves.

The excess keys are cut off by a grinder.

So, the shaft with the eccentric is ready, the master puts the washers on the shaft, and collects the lower part of the structure.

Here is such an element of the mechanism at this stage.

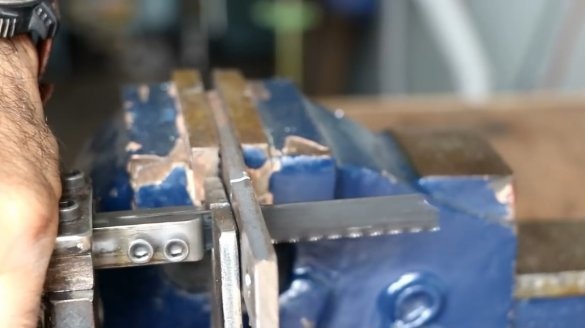

From the steel square, the author plans to make guides for the moving part of the mechanism. He tries them on to the manufactured part, and marks the places of drilling.

Drilling through holes in them, baits bolts.

He tries on the future moving part, checks for any backlash.

Then marks the two stop bolts in the moving part. Drills holes in it.

Now it cuts the threads in the resulting holes, and makes a longitudinal cut for fixing the canvas.

Perpendicular to the cut also drilled two holes, and cut into them a thread for pressure bolts.

Then screw the stop bolts into the moving part, and put them on the bearing.

Installs and fastens the second cover, pressing it with bolts through the guides.

So, the main mechanism is ready, it remains to focus on the canvas. He will make it from a steel strip.

Makes an incision according to the markup, bends the workpiece at an angle of 90 degrees.

Having drilled the necessary fixing holes, and having made a cut for the blade, it fastens the corner to the mechanism.

As planned, when the shaft rotates, the moving part is displaced.

The author fixes a blade from a hacksaw for metal in it.

It remains to clamp the shaft of the device in the chuck of a screwdriver - and the nozzle is ready for work. You can also use an ordinary electric drill.

This is how easy the device copes with prosperity.

PVC pipe is also not a problem.

Tests have shown that even a thick steel plate can be machined without any problems.

Thanks to the author for a very interesting screwdriver tip!

Good luck to everyone, good mood, and original ideas!