This article will be interesting to all craftsmen working with wood and the furniture.

In it, the author of the YouTube channel "Gökmen ALTUNTAŞ" will tell you how to make a very convenient device for drilling grooves in the ends of the material under dowels. Moreover, it has the ability to automatically search for the center, which greatly speeds up the work.

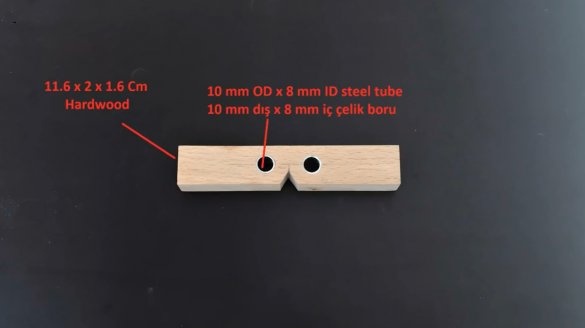

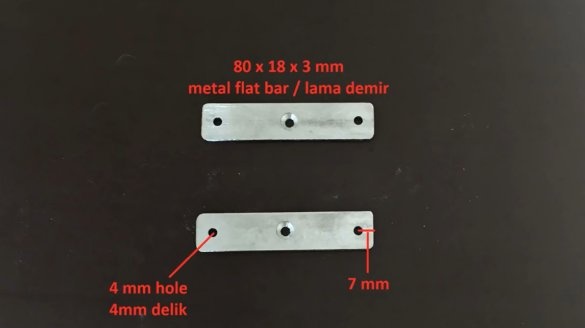

All sizes of blanks are in the photographs at the end of the article.

Materials

- Steel strip, preferably made of stainless steel 18X3 mm

- Steel tube with an outer diameter of 10 and a wall thickness of 8 mm

- Wooden block

- Boards

- Wooden dowels 8 mm

- Wood screws.

Instruments, used by the author.

- Screwdriver

- A circular saw

- Band-saw

- Vise, clamps

- Rubber mallet

- Grinder, cutting disc

- Electric jigsaw with metal blade

- Drilling machine

- Corner, ruler, pencil.

Manufacturing process.

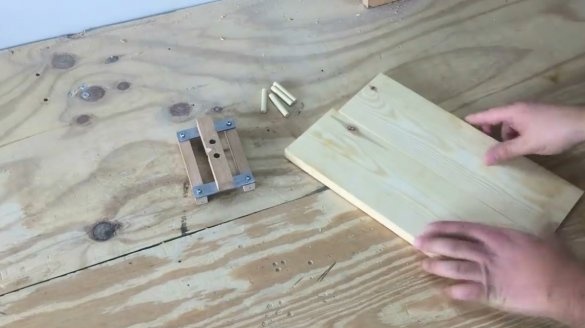

Cut three hardwood sticks on a circular saw.

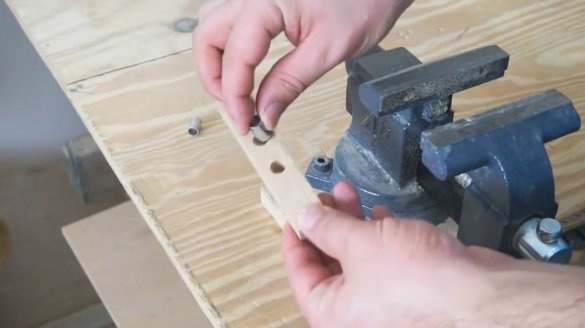

In one of them drills a pair of holes 10 mm in diameter, at an equal distance from the center of the bar.

He picks up a steel pipe, clamps it in a vise and puts a marking.

Slices with an electric jigsaw, gets two bushings.

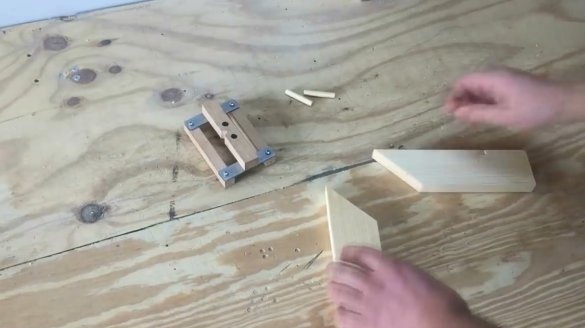

Inserts bushings into the holes and presses them in with a vise.

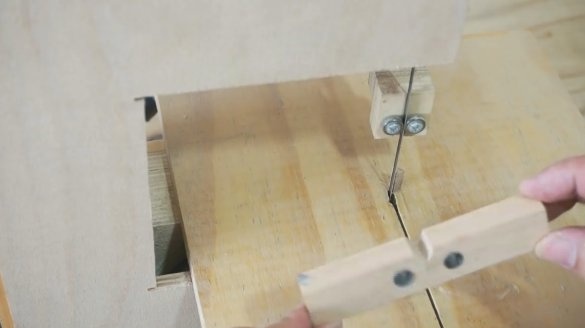

Now marking the triangle, makes a cutout on the workpiece.

At the edges of two other blocks, drills holes for mounting bolts.

In a block with bushings it makes shallow blind holes.

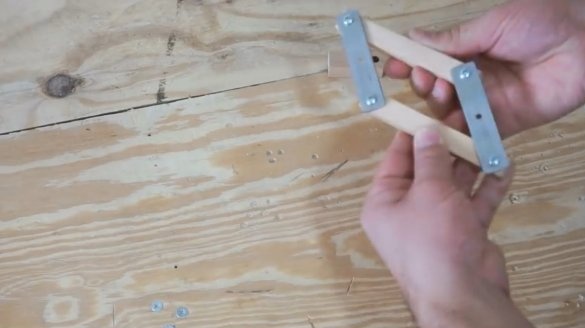

An interesting solution to the machine from the grinder. Cuts two pieces of steel strip with it.

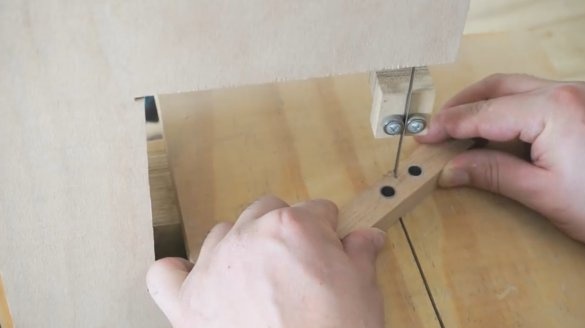

Now in each workpiece drills holes 4 mm for bolts.

Then countersinks the central hole - the head of the bolt should be flush.

Screws the plate to the cubes, countersink down. It turns out here is such a flexible design.

Now bolts the bar with guides.

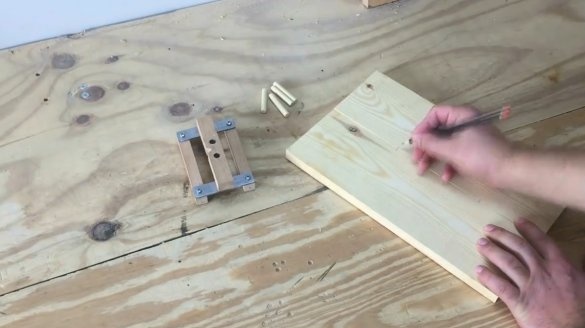

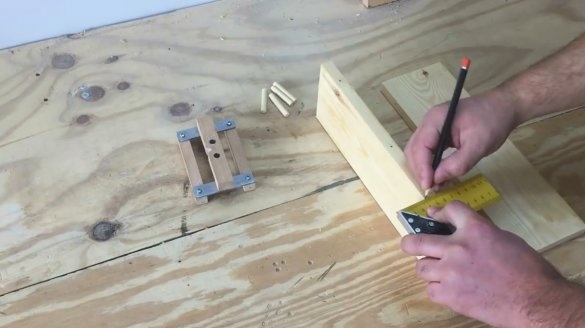

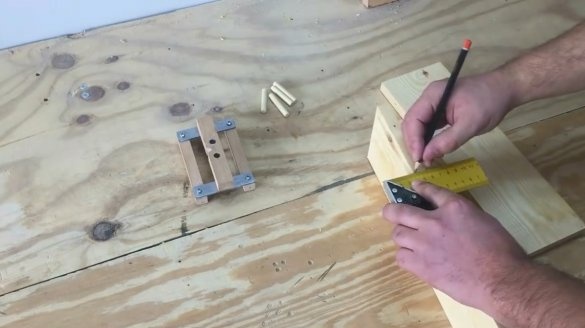

Marks centers for drilling on two boards.

Sets the conductor, sets the center and mark. Drills 4 holes in each board.

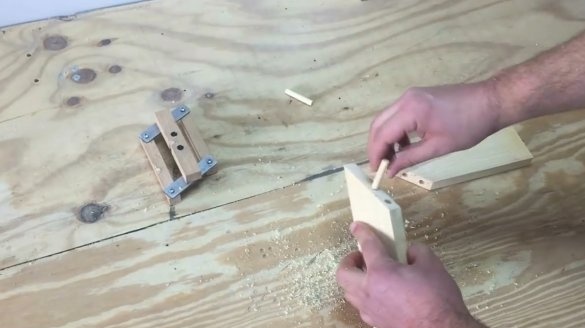

Inserts dowels into the holes, and clogs them with a rubber hammer.

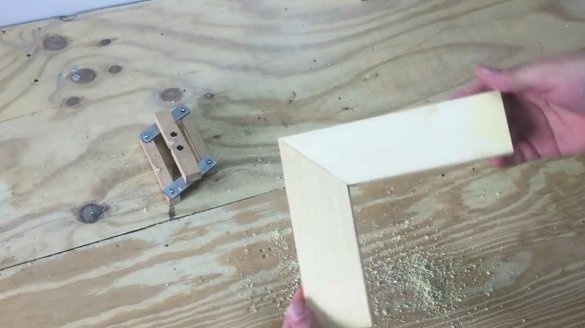

It connects two parts, also helping with a hammer. A very tight connection turned out. No slit or skew.

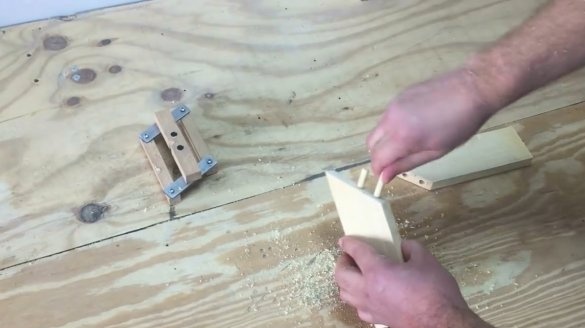

Now he is trying to make an angular connection. Marks the center, presses the conductor with a clamp.

Now drilling has become even more convenient and accurate.

Inserts dowels and connects parts. Great fit elements.

And here are the copyright blueprints.

Thanks to the author for the idea of a simple but useful carpentry conductor!

All good mood, good luck, and interesting ideas!