This article will be interesting to everyone who often forgets to stop a certain process on time.

In it, Jack, the author of the YouTube channel "Jack Houweling", tells you how to create a very interesting sand timer from a regular board, sand and plexiglass.

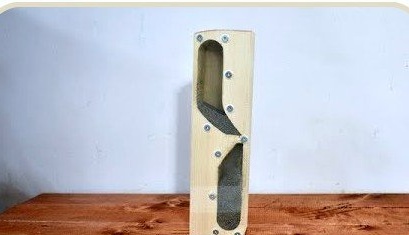

Before you is a sand timer, but somewhat unusual. When sand is poured into the lower cavity, the timer capsizes, making a distinctive sound. Thus, giving an audio signal about the expiration of the time interval.

In the author's version, sand is completely poured into the lower cavity in about 2.5 minutes, after which the watch needs to be turned over, and all the magic will be repeated again. This time interval is very suitable for boiling soft-boiled eggs.

How does this happen? Why does the timer flip over to its long side? Take a closer look: both short sides are slightly rounded at one end, and when the center of gravity of the structure is shifted due to moving sand, the timer is thrown over. So it is ready for use again.

Materials

- Plexiglass

- Quartz sand

- Steel wire 1-2 mm

- Wood screws.

Instruments, used by the author.

- Screwdriver

- Forstner drill

- Sieve

- Drilling machine

- screwdriver

- Belt sander

- A circular saw

- Band-saw

- Ruler, pencil, square.

Manufacturing process.

And now the author will tell us how to do it. So, the author cuts the main part of the timer from a wooden bar with a circular saw.

Then marks the future sand chambers, and cuts the lower and upper parts of the workpiece at a slight angle.

Now, having installed the Forstner drill, he drills a pair of holes at the edges of the chambers. And drills them from two sides, so that there are no chips.

Strikethrough elements of the workpiece must be removed, and a hole should be made in the central part.

It fixes the workpiece in a vice, and with the help of an electric jigsaw cuts the contours of the chambers.

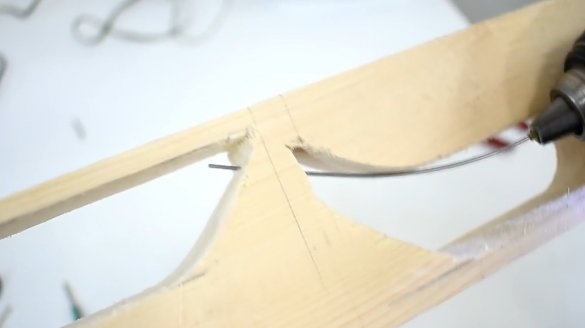

Now he will try to drill a hole in the adjacent chamber so that sand can penetrate there. But the author does not have such a small drilllet that it can cope with this delicate task. Craftsman decides to use a piece of wire for these purposes. However, the diameter of the wire is slightly smaller than the hole that the chuck can form.

Silent resourcefulness and .. a solution is found.The author is going to use an electric cable, from which he cuts a piece of plastic, insulation. He pushes this insulation onto the wire, and now it is remarkably fixed in the chuck.

Next, the author glues the back panel. This is plywood from Baltic birch. The board is approximately 3 mm thick.

Excess back wall is cut off with a band saw.

After the glue dries, it processes all sides of the obtained workpiece using a belt sander.

Now we need to check whether the sand passes. It is enough to take a small amount of it and if it does not go into the lower chamber, you will have to expand the hole somewhat.

Jack sifts the prepared sand through a sieve, approximately one measure, and pours it into one of the chambers. Checks - everything works.

The last step is to lay a sheet of plexiglass and fix it with screws. The author cut out the material in several large sizes. He is going to cut off the excess later. He then marks the places where holes will be drilled.

Further actions are carried out on a drilling machine. But you still need to hold the sheet of plexiglass, it clings to the drill and bends it. After drilling, each hole countersinks a little.

Pre-drills holes in the main part of the timer, and fixes the cover with screws.

Now cuts off the excess cover with a band saw.

Sanding a bit with sandpaper and the timer is ready!

So, as sand is poured from one chamber to another, the center of gravity shifts and the timer falls.

To continue, simply turn the timer upside down.

Thanks to Jack for the original idea of a sand timer with a beep!

Good luck to everyone, good mood, and interesting homemade goods!