Yes, yes you were not mistaken, this article will be about how to make a knife, and plastic bottles will serve as the material. What they don’t do from bottles, but I did not expect to see a knife made from them.

Nevertheless, the blade of the knife turns out to be quite durable and workable, the author unfortunately did not report how much the knife holds the sharpening.

Tools and materials.

-Scissors

-Sharpening stones

-Jigsaw

-File

-Baking oven

Parchment paper

-Marker

-Plastic bottles

-Vegetables to check :)

Manufacturing process.

To start the process of making a knife, you need to stock up on plastic bottles, for your crafts The author used 10 bottles. Bottles must be thoroughly washed from the contents, remove stickers and rings from the caps.

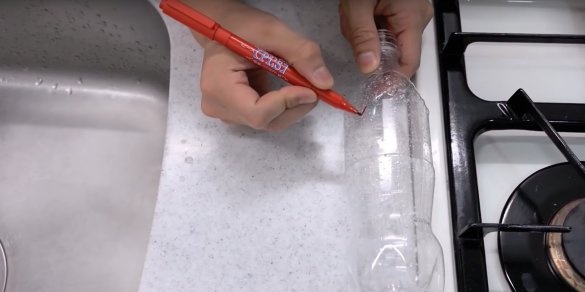

In order to make the knife interesting, the author decided to make it colorful. To do this, he paints several bottles with markers of various colors.

At first, the author simply begins to color the bottle, but the process is very long. Therefore, the author removes the rod from the marker, pours the paint on the bottle and distributes the paint with a finger.

The author will use two colors.

Now you need to grind all the bottles and melt. To do this, the author puts parchment paper in a baking sheet. Cuts bottles first with ribbons. Each tape should be wiped from moisture.

After the tapes are cut and rid of moisture, they can be cut into small pieces.

The author adds some more unpainted bottles. In total, the author used 10 bottles.

The resulting mixture must be mixed.

The edges of the parchment must be tucked so that the material does not spread much during baking.

Sent to the oven, temperature 240 degrees.

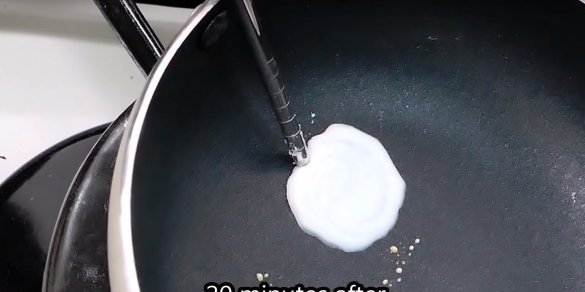

While the material is baking, the author shows that two different color options for baked plastic can be made.

If the molten plastic cools quickly, it will remain transparent.

And if the material is allowed to cool slowly, about 20 minutes, then it will turn white.

Meanwhile, the plastic in the oven has already been prepared, you can safely

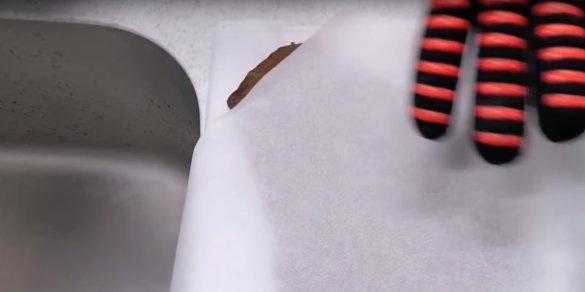

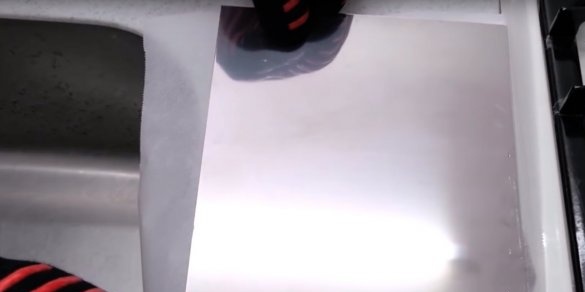

The author decides to make a knife in white, and therefore allows the plastic to cool for 20 minutes. At the same time, he takes out the workpiece, puts it on a flat surface and presses it with a sheet of metal so that the form, after cooling, retains an even plane.

After 20 minutes, the author removes the sheet of metal, cleans the plastic of parchment. The result is such a pie.

Now the author draws the contours of the future knife on the form using his favorite kitchen knife for this.

Since after baking the material turned out to be very dense, in order to cut a knife, the author uses a jigsaw with a diamond string. I think that you can speed up the process using angle grinders with a diamond disk.

The final form is attached using a file.

Using sandpaper with a grain size of 80, the author polishes the surface of the knife.

The author uses a diamond grindstone with a grain size of 140 to form the slopes of the knife blade

Gradually reducing the granularity of grindstones, the author brings the ideal state of the knife blade.

Well, the knife is ready, but the truth is so far without a handle.

Now you can test his abilities. The author shows that the knife easily copes with paper.

And vegetables on his shoulder too.