In this article, Jack, the author of YouTube channel "Jack Houweling" will tell you how to make a simple and compact goniometer.

The reader is offered a description of the process of creating a protractor, moreover, such a compact option that would easily fit in your pocket.

Materials

- Spoils from bog oak and maple.

- Brass bolt, nut.

Instruments, used by the author.

- Band-saw

- A circular saw

- Vise, file

- Belt sander

- Hacksaw

- vernier caliper

- Marking ruler, marker, pencil

- Drilling machine, or screwdriver.

Manufacturing process.

And the author of this project begins with a pen. For her, he chooses a hardwood, the so-called bog oak. And for the “blade” he uses a maple board.

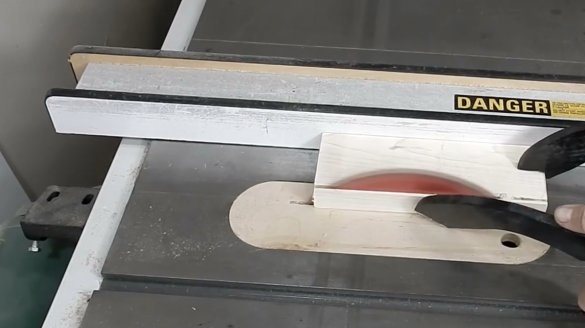

Having decided on the materials, he cuts the workpiece with a circular saw.

First, Jack cuts a groove in the bar. The groove should be cut at an angle of 45 degrees. This is done so that the blade can be locked inside the handle.

These notes will allow Jack to make a cut of the desired depth. In addition, with an orange marker, he puts a mark on the stop, too, to mark the depth of the gash at which you will need to stop.

If you now check the resulting groove with a large goniometer, then the blade adjustment will be quite accurate.

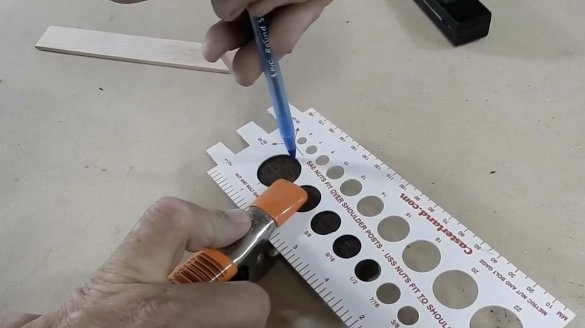

To cut a strip, the author first measures the gap with a vernier caliper. It is 3.85 mm.

For the blade, he will use a piece of maple board.

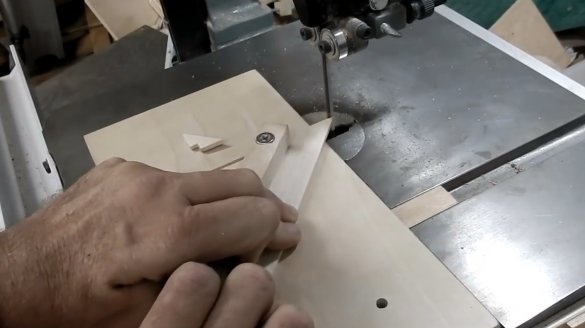

At the final stage of work on this part, Jack uses a band saw. It removes excess material and cuts the part at an angle of 45 degrees.

Now you can insert the blade into a pre-prepared groove, and check the fit. Great sitting!

Next, cut the body of the future goniometer to the desired size. As mentioned above, the author set the task to create a pocket goniometer.

Jack processes the saw cut place on a belt grinder, giving the edges of the product a neat rounded shape.

The master is going to use a connecting bolt and a knurled brass nut as a clamping bolt.

He then drills a slot. The bolt has a diameter of 7.5 mm, but the author will use a drill with a slightly larger diameter.

Irregularities of the edges are slightly processed with a file.

After the groove is drilled and processed, it becomes clear how long the blade should be.

The next procedure is sawing off the bolt. The author cuts off the nut and bolt with a mini-hacksaw.

So, the author’s goniometer is ready! The locking mechanism also works great.

The author achieved what he wanted - this miniature measuring device fits easily into the pocket of your clothes, it can be easily put into a small box for tools.

Thanks to Jack for a simple but useful measurement. device!

All good mood, good luck, and interesting ideas!