Hello, to all the inhabitants of our sites. We all know that bike It is both a means of transportation and a simulator for pumping up legs, for losing weight, for strengthening the heart, and much more. But today we will consider the bicycle as a means of transportation. When there is no car or anything else, a bike will be a great solution to overcome small distances.

A long-distance journey requires great endurance which ordinary people may not have enough. At this moment, probably many dreamed of a moped or electric bike. But it’s worth looking at their prices and long distances do not seem so big. Some abandon this venture, pumping their legs and stamina through sweat and willpower. Others get bikes, mopeds, cars, etc. There are also craftsmen who have no desire to swing and have no money, but there is a motor from a chainsaw, lawn mowers, etc. lying around in the barn and there is a bit of ingenuity, tools, experience, etc.

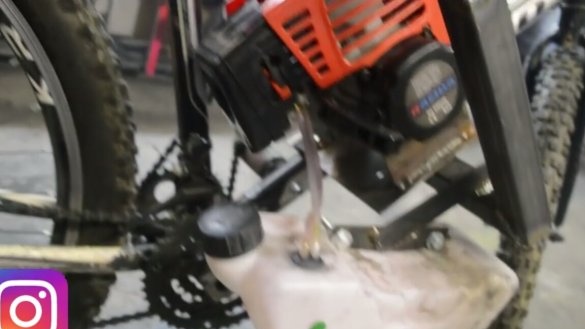

We’ll talk about such a craftsman today. He did homemade from a motor chainsaw and great, while spending quite a bit. If you also want to do the same homemade, then listen. I will try to explain in detail to you the whole process of his work. But if something is not clear to you at the bottom of the article, I will leave a video where you can see the manufacture of this homemade product with my own eyes.

For manufacturing you will need:

1. Motor from a lawn mower

2. Bike

3. The pedal sprocket from the old is great and the sprocket from the wheel

4. Drill, screwdriver, welding, Durka, etc.

Step 1. Site

At this stage, the platform is disconnected from the motor, two holes are made in it in order to fix it on the bike. Further, the site is attached to the great. The head from the drill is cooked to the motor shaft (the main thing is to keep the alignment, otherwise it will vibrate very much and you will ride like stones). Now, from a piece of pipe, the author does something like a clamp (I didn’t understand why he made it, maybe because the frame is aluminum and you can’t cook it, or he) didn’t want to damage it.) Welding a bolt and nut to it as in the photo.

Step 2. Frame

Now the frame is made to install the motor.The frame is cooked from the profile, as in the photo or video, and the motor is installed. Further, a suspension is made from several steel or iron plates to fix the tank for the motor on it. The next step from the old bike is removed pedal asterisk from which the hub is cut off. A hub is also cut off from the wheel, only an asterisk is needed from the hub.

The author decided not to use the head from the drill, so he cut it off leaving the shaft. A small sprocket was welded to the rod. Now alignment has become an even bigger problem, cut out the head so that the cut of the shaft is as even as possible. To align and weld the sprocket over this cut. If you weld the sprocket obliquely, the chain will fall. Then a large sprocket is welded to the pedal sleeve is large and the sleeve is fastened to the bicycle for the chain tie.

Step 3. Test

That's all now you can enjoy your homemade work. Well, to be honest, it is unlikely that anyone will take up the construction of this homemade product. But if you come from, then I wish you good luck and fewer problems (Which oh how they will be, maybe). The maximum speed is 30km / h. But if you change the asterisks, large to motor, small to large, then the speed will be much higher. And from myself I’ll add that if the frame is aluminum, then you should not attach a motor to it, aluminum is soft metal. From vibrations, the mounting bolts can become loose and the entire motor will go to the sides, the chain will constantly fall down. And I would not put a gasoline engine based on today's fuel prices, it is better to put an electric engine. Having added some food. In the internet you will find many videos, articles on this topic. That's all, for now, everyone, like and leave your comments about improving this homemade product, maybe this will help someone.