And if the emphasis is made folding, it will be generally wonderful. Folding emphasis will not take up much space in the trunk compared to its usual counterparts. Let's see how it can be made.

Materials and tools.

Manufacturing process.

Making folding shoes will not take you much effort and time, and you won’t need specific tools.

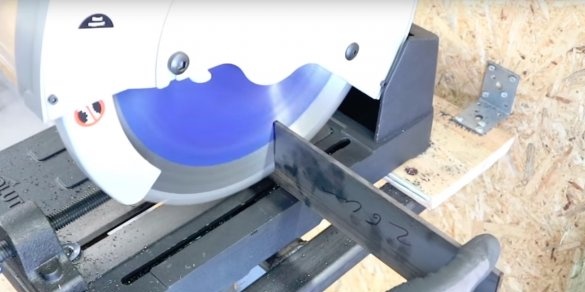

First of all, the author cuts several metal plates. The thickness of the metal is 5mm, the width of all strips is 80mm, the length of the strips is 20mm, 200mm, 160mm, 300mm.

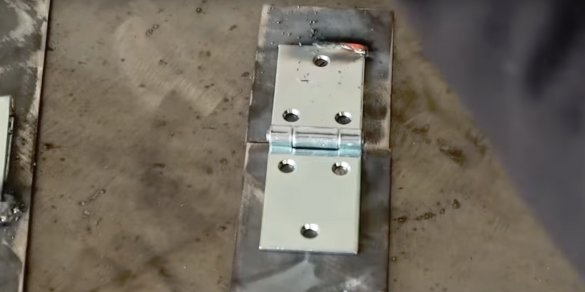

Also, for manufacturing, you need two door hinges, naturally, it is better to take the hinges of good quality, with a sufficient metal thickness.

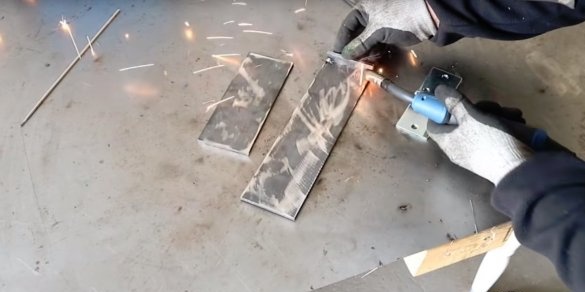

The longest segment will serve as the base of the stop, the author welds the smallest segment of 20 mm to one of the sides of the base, perpendicularly at right angles. This will be the back of the shoe.

Now you need to grab one loop to the base, but before that you need to understand where it will be located. To do this, the author puts a 160 mm segment on the platform, while resting on the back of the shoe, while the contact angle of the segment with the platform should not be perpendicular, the segment should be inclined to the front side of the platform. About 75-80 degrees in relation to the platform. The author applies a 200mm piece to the upper part of the segment, lays its lower part on the base, puts a loop in the resulting corner and marks its location. This loop can now be grabbed to the base.

Next, the author puts 200mm and 160mm lengths side by side, applies a second loop on top and grabs it.

The resulting structure can be welded to the loop located on the base.

The author checks whether everything turned out right and welds all the seams finally.Please note that before the triangle (when the shoe is unfolded), a small part of the platform remained to protrude, the author did it on purpose, it is on this part that the wheel will roll, pressing it with its weight and not letting the shoe slip on the road surface.

Such a design came out, it remains only to grind and paint the product.

After drying, you must of course check the product. The device properly unfolds and develops and at the same time has a neat appearance.

That's how it looks when folded, it won’t take up much space.

That's all the wheel chock is ready for use, now car You can safely leave it on a slope and do not worry that it will slide.

Such emphasis can be made for trucks, only on a larger scale and you will need to look for loops more tightly.

On this, I say goodbye to you, all good, good luck and always in a good mood !!!