Greetings to you readers.

In this article, you can familiarize yourself with the technique of making a carbon fiber kitchen knife. This material is also called carbon fiber or simply carbon.

Creating this homemade, the author had to sweat pretty, the manufacturing process was quite complicated. By the way, you probably already know this author if you read an article about making a knife from plastic bottles. This is a guy from Japan, and as you know, the Japanese are real masters in making knives, so let's trust this guy and watch the manufacturing process.

Tools and materials.

-Scissors

-Sharpening stones

-Jigsaw with a diamond string

-File

-Baking oven

-Construction hair dryer

-Two sheets of metal

- MDF plate 220 * 320mm

- Guillotine for paper (optional)

-Clamps

-Vacuum packing machine

-Packages for vacuum packaging 250x350mm

Parchment paper

-Marker

- Screws for fixing the handle

-

Epoxy resin

-Scotch

-Vegetables to check

Manufacturing process.

The author decided to make this knife from scratch, so to speak, and for this he needs to make it himself. The master takes a piece of MDF board with an approximate size of 220x320 mm (the size of the board depends on the size of the future product). It is also necessary to check that the MDF board fits in a bag for vacuum packaging. For packaging, the master will use packages of size 250x350mm.

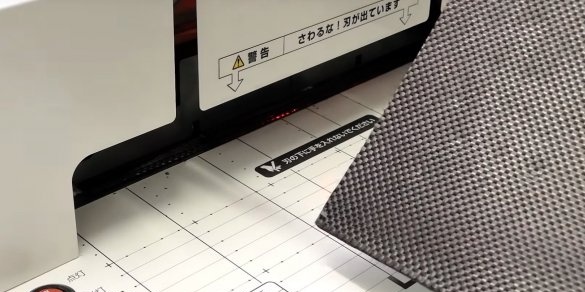

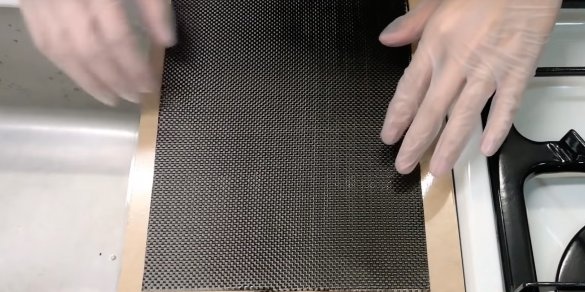

After fixing the canvas on the wall, the author marks it according to the size of the MDF board and applies strips of adhesive tape along the lines of the future cut, apparently so that the fabric does not mess up during cutting.

Slices sheets of fabric, a total of 10 sheets.

Now the master folds all the sheets and aligns all the edges using the paper guillotine. Although why he does this remains a mystery to me, since the edges in the finished carbon plate will not be used, so I think you can safely skip this step.

To glue carbon sheets we need epoxy. The author mixes its components first in a glass, and then pours the resulting mixture onto a tray and mixes it thoroughly again.

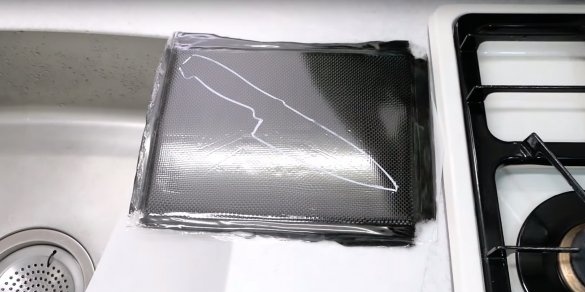

The author will form carbon fiber on the MDF sheet, but during the hardening process, the epoxy will stick to the sheet. To avoid this, the author puts on a MDF vacuum bag and pumps out air. Also thanks to this, the carbon sheet will have a glossy surface and will not require additional processing.

So, on the already packed MDF sheet, the author begins to lay out sheets of carbon fabric, carefully impregnating it with epoxy resin, and expels air bubbles with a plastic spatula. Thus, it forms 10 layers of carbon fabric.

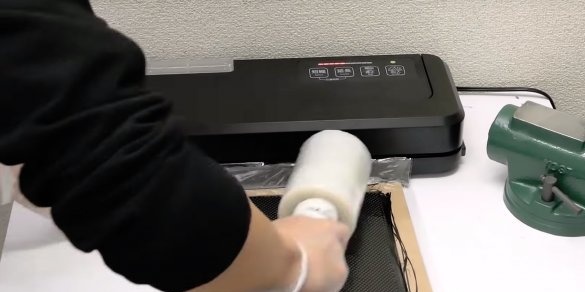

The author places the resulting pie in a vacuum bag and evacuates, while you need to get rid of air bubbles. The author does this with a soft foam rubber roller.

If you think that is all, you can safely leave the workpiece and wait until it hardens, then you are mistaken, everything is just beginning.

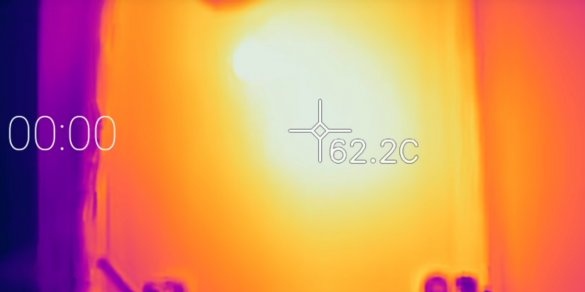

Now the author clamps the workpiece between two stainless steel plates with clamps and heats it with a building hair dryer. By heating the plate to 60 ° C throughout, you just think for 180 minutes. This guy is patient with patience.

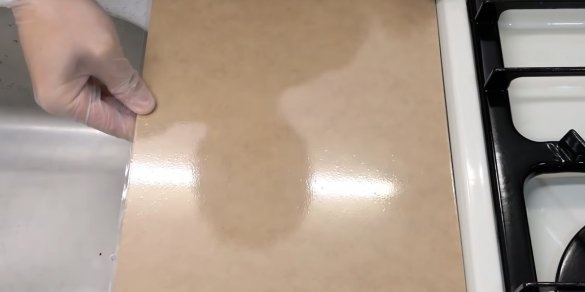

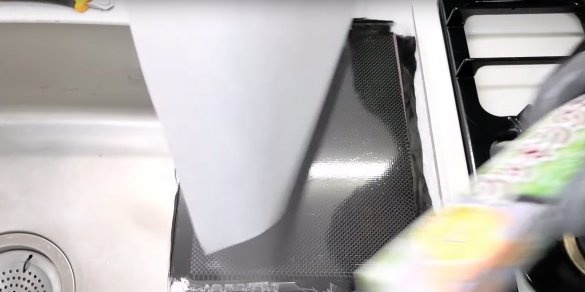

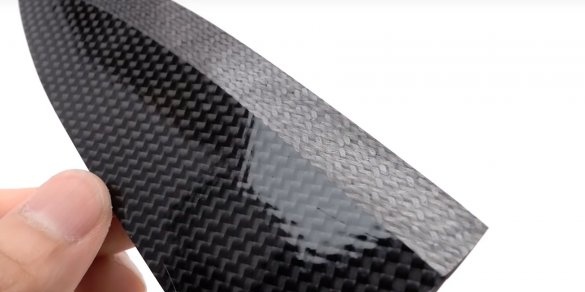

After three hours of fun, the author retrieves an almost finished sheet of carbon fiber. Why almost? Because our author will not calm down in any way, now he presents himself as a real baker. Having rid of the vacuum packaging and laying the carbon in the baking sheet on parchment paper, he boldly sends it to the oven, where the carbon pie is cooked for another three hours at a temperature of 180 ° C. Yes, but I said that not everything is so simple.

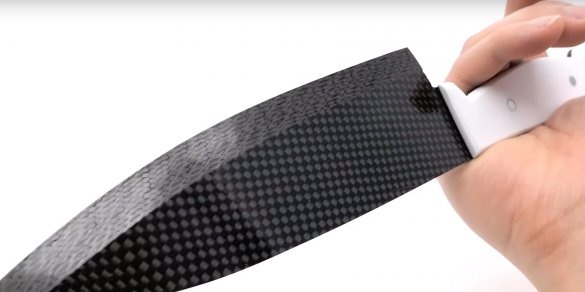

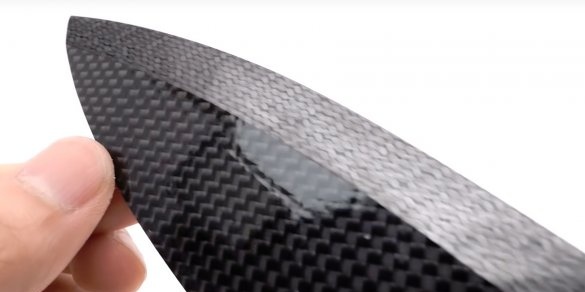

And finally, the time has come when the carbon fiber plate is ready !!! It remains only to cut out the profile of the future knife from it. Just, yeah, in carbon fiber

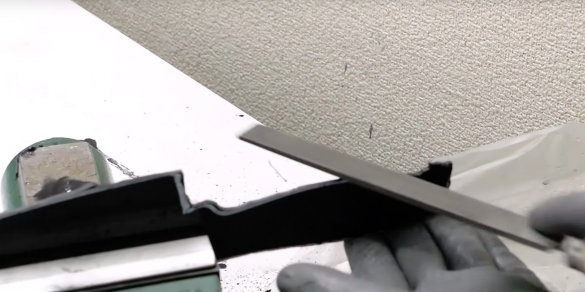

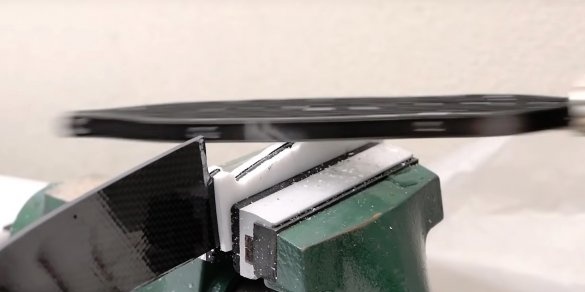

The author draws a knife profile on the plate and using a hacksaw with a diamond string, easily cuts the knife for the Nth amount of time, sweating pretty much and probably using profanity in Japanese.

In order to test the strength of the resulting carbon fiber, our Japanese master puts an unnecessary piece of carbon fiber on two heights and loads it with his weight. As you can see, the test passed successfully, the carbon is not broken and the author was not crippled. Wonderful.

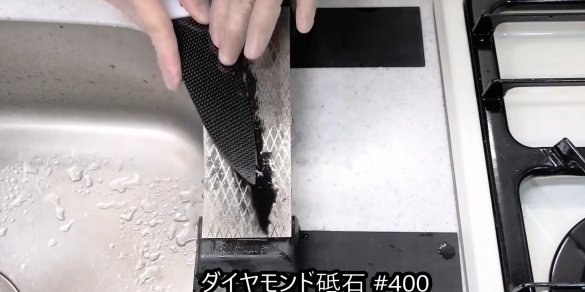

We continue. Armed with a file, the author arranges the shape of the knife. The final profile is attached using a 400 grit diamond grinder.

As can be seen on the cut material turned out to be dense, without bubbles and defects.

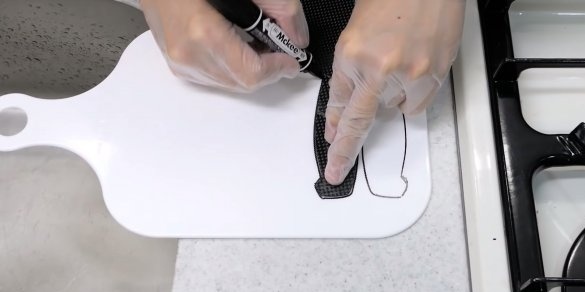

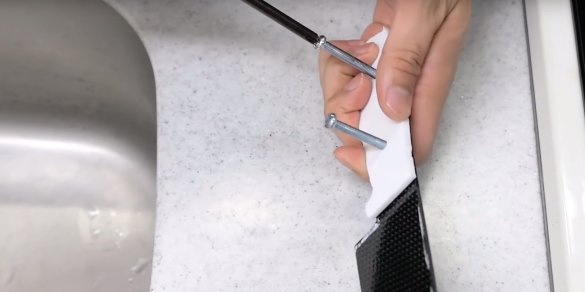

The master decided to make a handle for a knife from a plastic kitchen board. To do this, mark the profile of the handle on it, cut it out with a jigsaw, here the process is much faster, this is not carbon. The ends are processed by a file, marking and drilling holes. Screws, cuts off excess and grinds.

Strange, but our Japanese samurai in every possible way wants to complicate the task for himself and refuses to use an electric tool. Drilling holes, cutting and grinding screws, all these operations the author performs manually.

After the handle is finished, the author only needs to finish the knife blade. Just, yeah ... This is a monotonous and painstaking work that requires utmost care and concentration

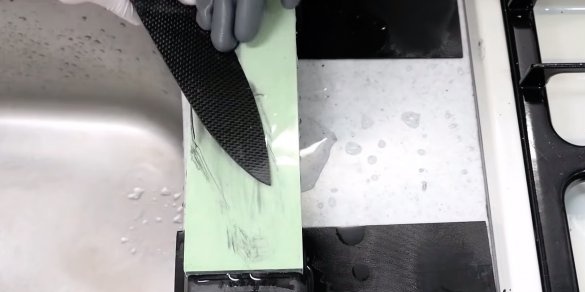

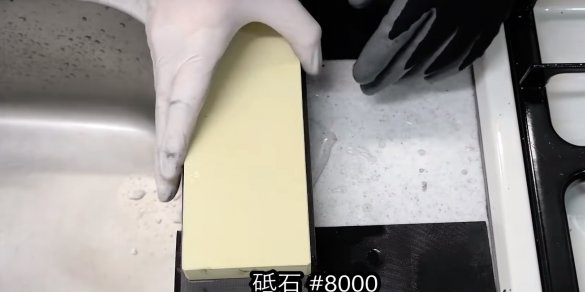

So, for the formation of descents, the author uses a grindstone with a grit of 400. The next grindstone will be with a grit of 1000, then 2000, so gradually reducing the grit of the stone, the Japanese brings the cutting edge to perfection. The last grindstone used by the master has a grain size of as much as 30,000.

On this carbon knife is ready.

Comparison of weight with a metal counterpart.

Now it’s worth checking the product in operation. The master cuts his favorite cucumbers and a tomato, and finally puts two stab wounds into the plastic bottle.