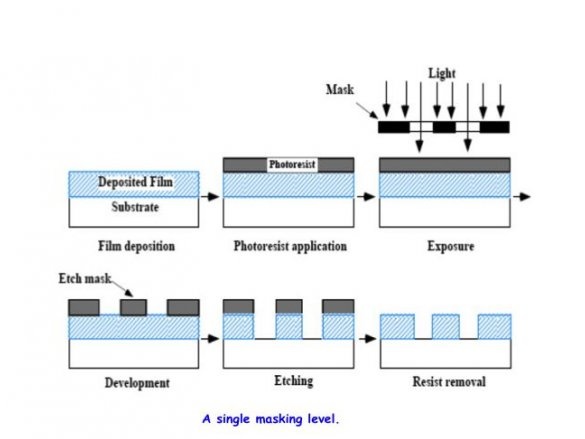

The author of Instructables under the nickname hdissanayake decided to revive the seemingly almost forgotten (recall B3-04) art of making printed circuit boards on glass. The following figure shows the stages of the process of obtaining a board using photoresist:

1. Covering the material with foil (in the case of glass, this will have to be done do it yourself)

2. Application of photoresist

3. Exposure

4. Manifestation

5. Etching

6. Removal of photoresist

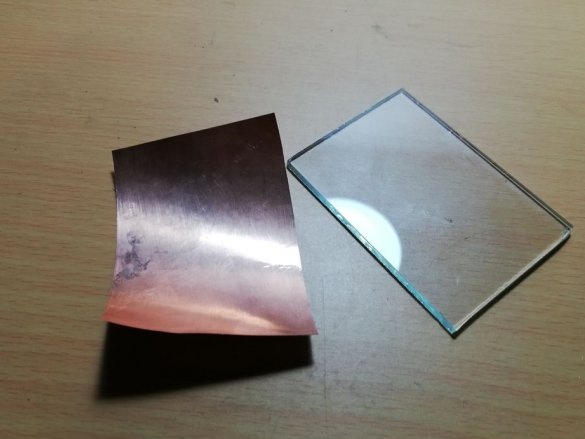

As a blank, the master takes a glass plate, always without sharp edges, and not like this:

On which copper foil will be applied (optimum thickness is 0.05 mm):

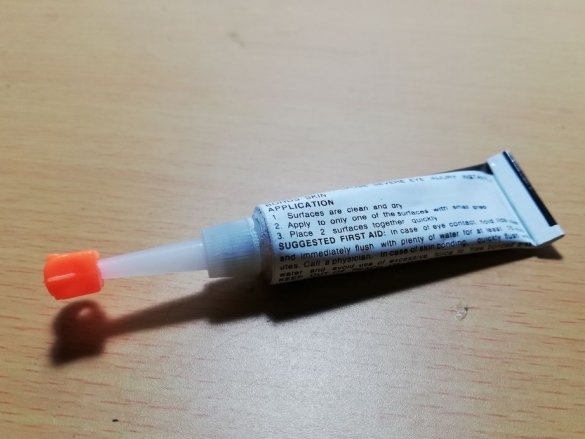

Using superglue:

And this is how film photoresist looks like:

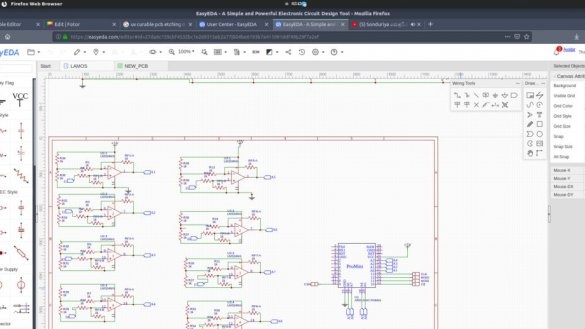

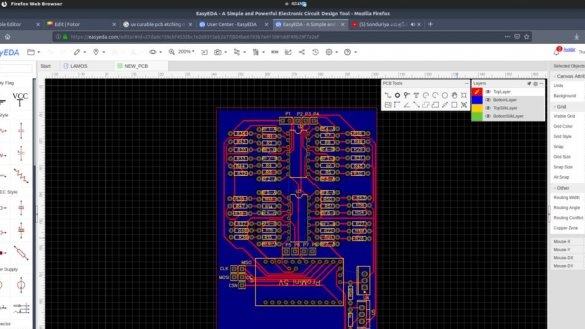

The hdissanayake circuit is in EasyEDA:

In the same program, he designs a printed circuit board:

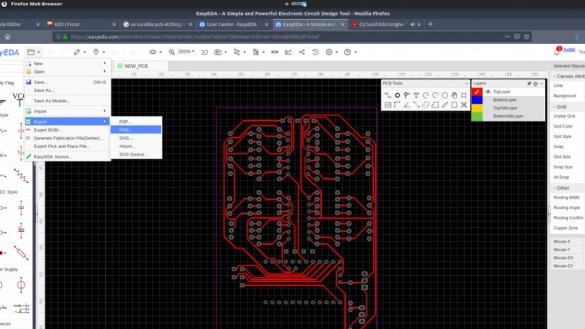

The figure which displays in a negative form, since this type of photoresist goes into an insoluble state under the influence of ultraviolet radiation:

Prints on film:

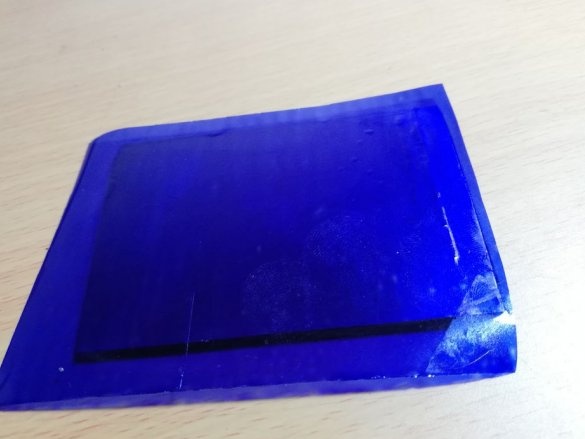

In this photo, both foil and glass are already degreased with isopropyl alcohol:

And here - they are already glued to each other with the help of superglue, which is important to apply evenly, without air bubbles and uncoated areas, squeeze out excess glue, wait until it sets completely:

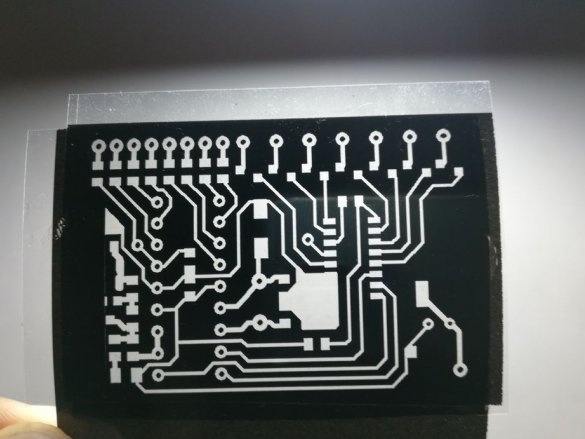

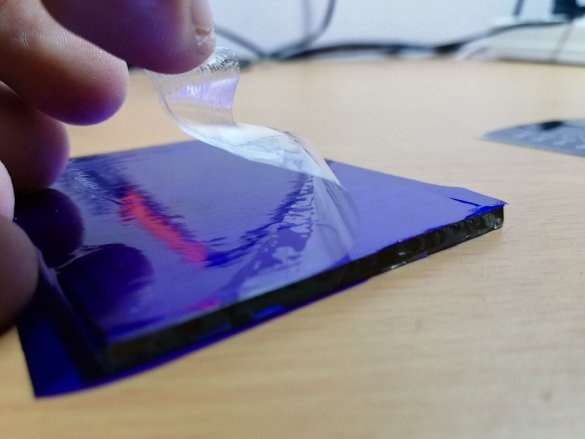

The master unsticks the photoresist from the substrate:

And sticks to copper, again avoiding bubbles:

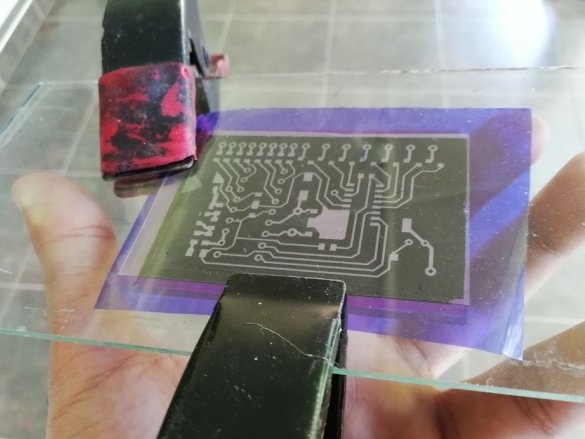

Imposes a printout on the film, presses it with glass, presses with clamps so that they do not block the ultraviolet:

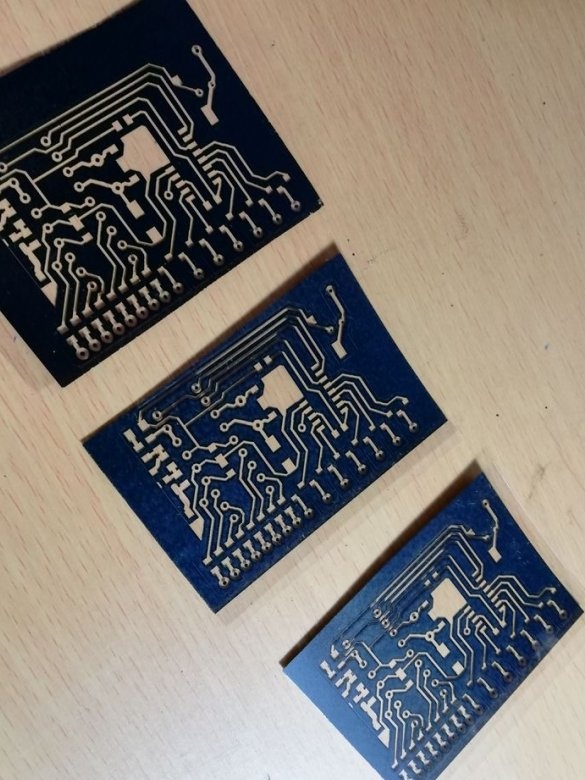

Exposes under bright sunlight for 5-7 minutes, after deleting the printout, the illuminated photoresist looks like this:

Adhesive tape removes the second substrate on the opposite side of the photoresist:

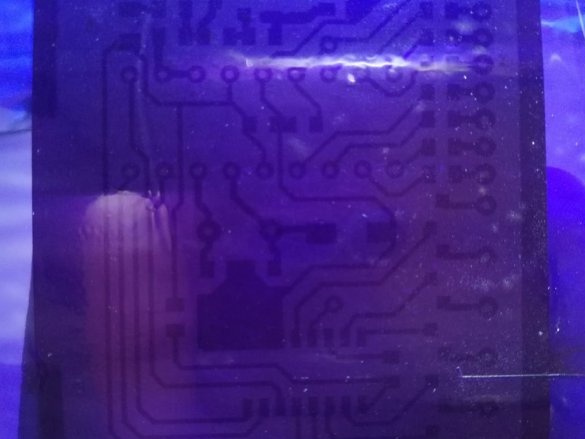

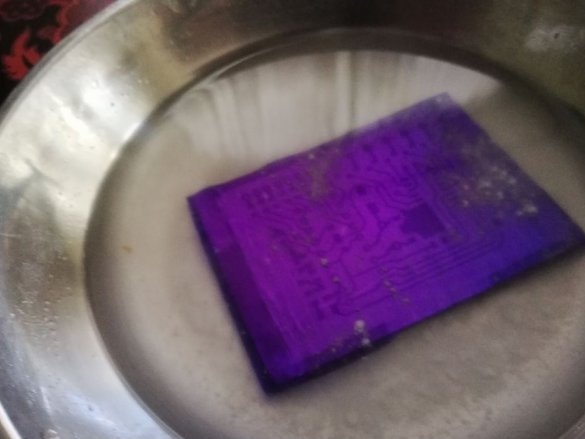

Places in a solution of soda for manifestation:

Washes the solution along with an unlit photoresist:

Alternates development and washing, until the photoresist is completely washed off on unlit portions:

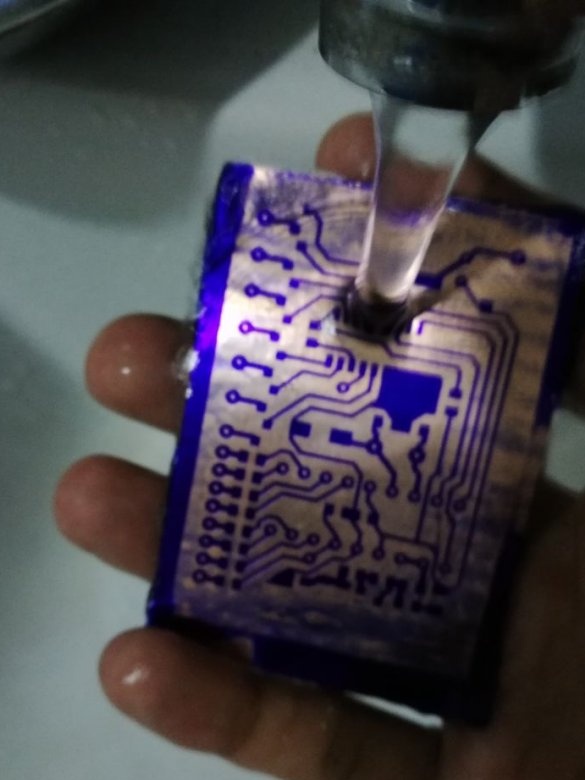

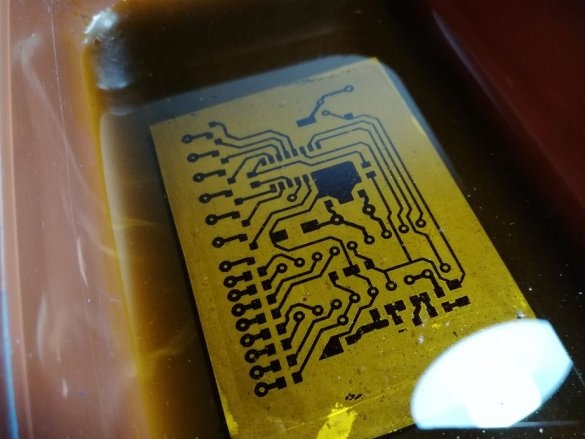

Poisons the plate with ferric chloride as usual:

Almost ready, it seems that ferric chloride dissolved after copper in unlit areas and superglue:

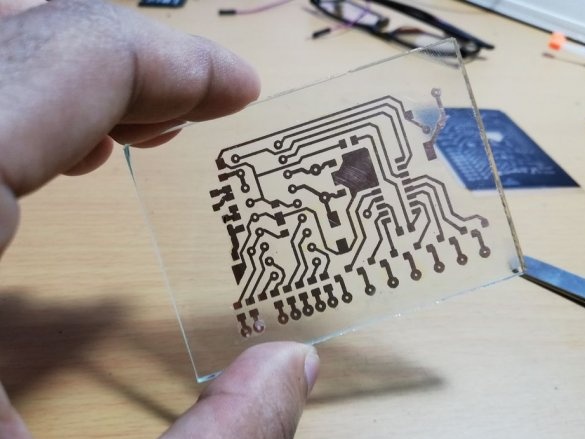

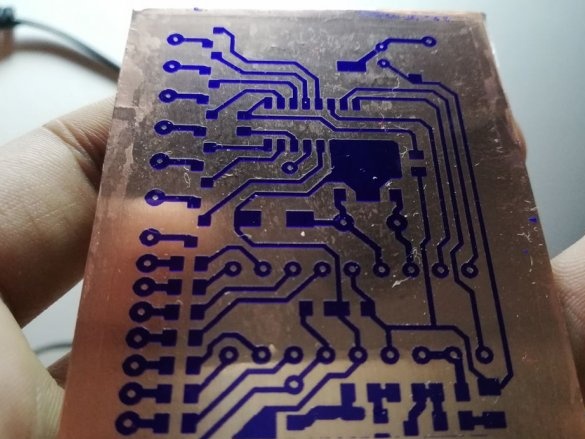

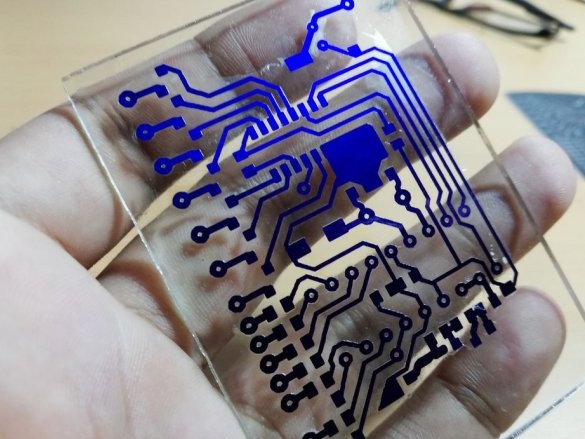

It remains to wash off the illuminated photoresist - if the water is hot, he will succumb. And the art of producing glass printed circuit boards can be considered revived. The board is ready for soldering.So, as shown in the photo, do not hold glass without gloves:

For obvious reasons, there can be no holes in such a board. But this is not so inconvenient. After all, there were no holes in the board in the same B3-04. And now, when there are SMD components for all occasions, it's even easier.