Hello everybody. Not a single work with metal is complete without welding work. Welding cuts and joins metal structures. But a good welding machine costs a lot of money. And buying cheap does not make sense, because it still makes flour with such devices. But the welding machine can be easily made do it yourself. There are many articles on the Internet on this topic. Well, almost all of these homemade devices are very weak. Or powerful, but huge, heavy and uncomfortable.

But there was one option for manufacturing a welding machine, made by its author channel kreosan. It differs from others in compactness and power. Today I will show and tell you the whole process of manufacturing this device. If something is not clear, then at the bottom of the article there is a video where everything is shown in detail.

Let's start, for manufacturing you will need:

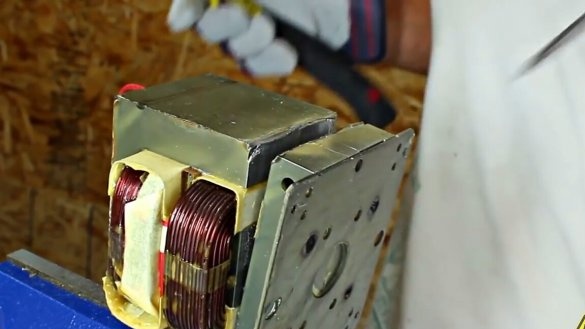

1. Two transformers from the microwave

2. Cable or wire of large cross section

3. Electrode holder

4. Epoxy adhesive

5. Grinder, hammer and tools

Step 1. Production

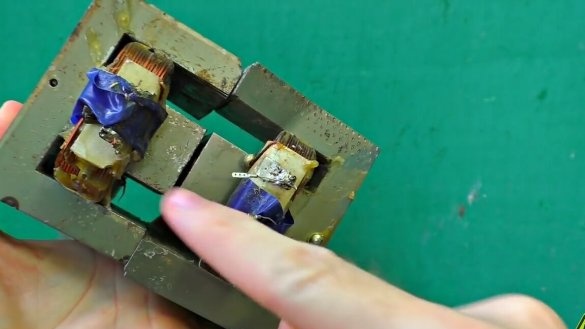

This device is very easy to manufacture, so I will describe everything in one step. In order for the device to turn out powerful and transformers need powerful ones from 1200W. For good electric welding, power is needed within 4000 watts. So if you remove the current shunts, then the power of the two transformers will be within 3900 watts, this will be enough. The secondary winding is removed from the two transformers and the current shunts are knocked out. Further, a cable is wound in place of the secondary winding. 54 turns are made and two taps at 40 and 47 turns so that the voltage can be changed. Then the transformers are glued together, as shown in the photo or video. Connects to the cable, electrode holder and ground.

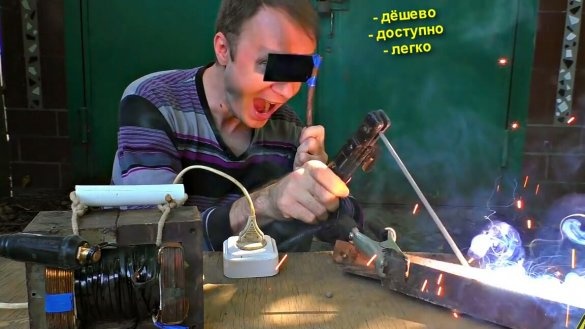

Step 2. Testing

Everything, the welding machine is ready, now you can test. Testing this homemadecan watch on video. There should be no insulation on the wire or cable, because the transformer is heating up or there must be some special heat-resistant insulation. There are doubts about epoxy glue. And so the welding turned out powerful, judging by the video.

I do not understand electronics. If there are concerns about the assembly and operation of this homemade product or improvement, then share them in the comments. This can be done, thanks for watching. If the article is suitable, then we like it.