The author of this homemade a lot of brushless tools and he decided to make another one - a drill that runs on high-capacity lithium-ion batteries.

Step 1: Tools and Materials

List of materials for this project:

High-speed fan from a server / PC 12V (with a current above 1.8 A)

Drillpro Adapter Kit

PVC fittings and pipes

Three lithium-ion batteries with a capacity of 18650 mA / h

Wires

Switch and socket for electric motor

Spray paints

Hot glue

List of tools recommended for this project:

Hacksaw

Drilling machine

Drill

Soldering tools (soldering iron, rosin, solder)

Step 2: Search for a brushless motor (cheap but powerful)

Now the first task is to find a brushless motor. There are two types of brushless motors: inlet and outlet motors. The term "input and output" refers to the position of the magnetic rotor in the engine. What you need is an engine with an external guide because of the greater torque it produces, since it has more torque compared to a type with an internal guide of the same size.

It was decided to use a brushless motor from a high-speed server / PC fan. It can be easily recognized. These fans have high current. This is indicated on the back of these fans. All that is needed for the fan to work is to connect it to a 12 V battery.

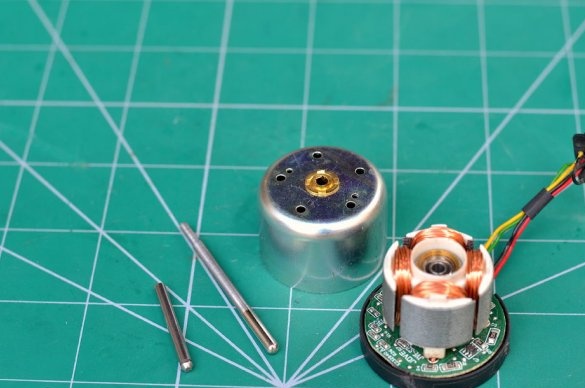

Now you need to pull out this brushless motor.

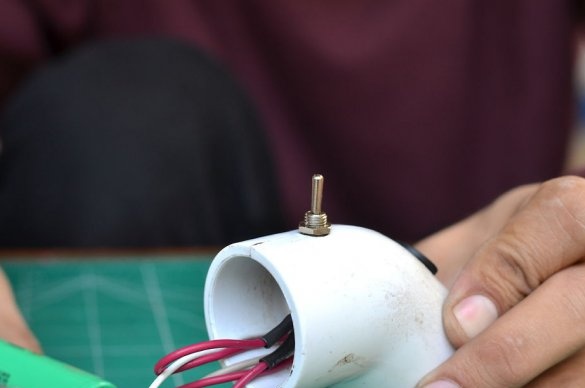

Step 3: Increase Shaft Length

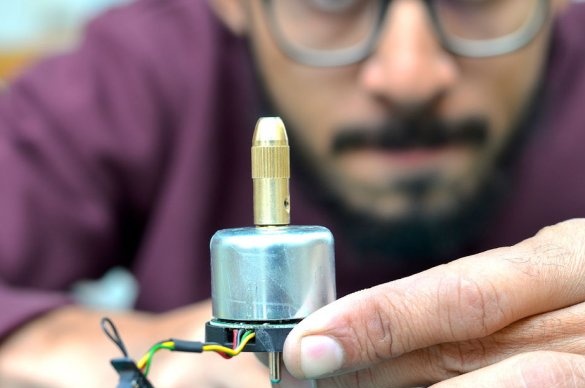

A brushless motor is already available, but you need to attach an adapter in which the bits and drills will be mounted. To do this, replace the existing shaft with a longer one. Remove the clamp from the back of the motor shaft to remove the magnetic rotor. The shaft moves inside the engine bell. To remove the shaft, you can use a nail or a suitable punch.

The diameter of the shaft is about 3 mm. A shaft of the same diameter was found in the old disk. The adapter will use the Drillpro adapter kit, ideal for making drills.

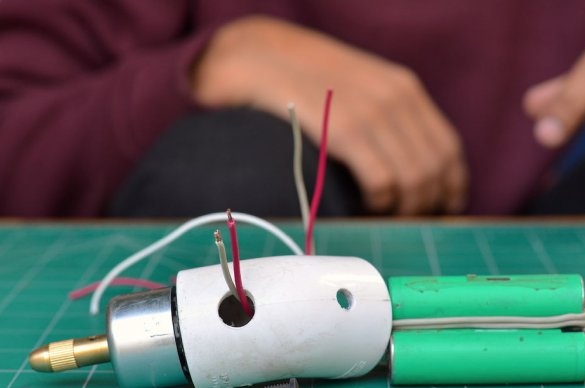

Step 4: motor holder

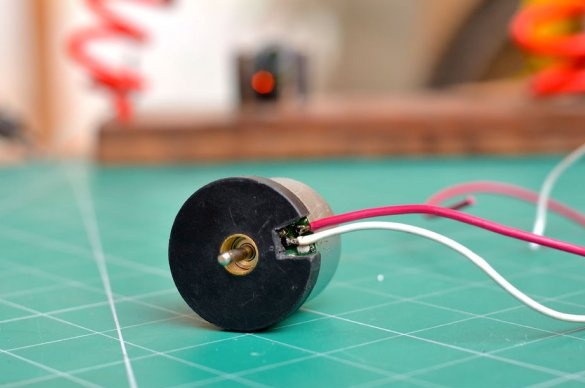

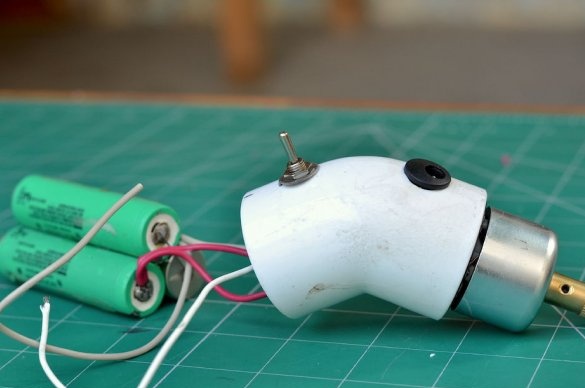

For engine mounting, a PVC fitting for water supply will be used, with a diameter of 32 mm and an angle of 45 degrees. It fits perfectly to the rear of the engine and makes working with the tool much more ergonomic.

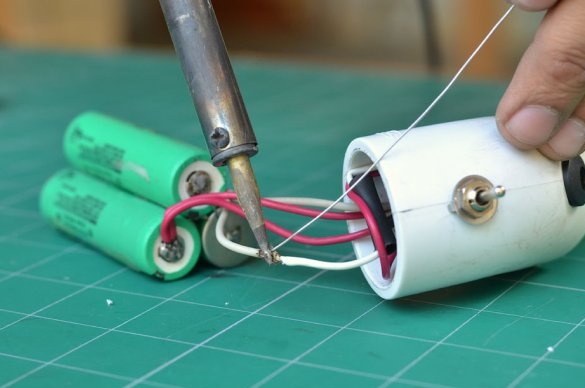

First, the rear plastic housing of the engine is polished, and then glued to the PVC fitting. Next, we shorten the wires to the desired length. The red wire is plus, and the black wire is earth.

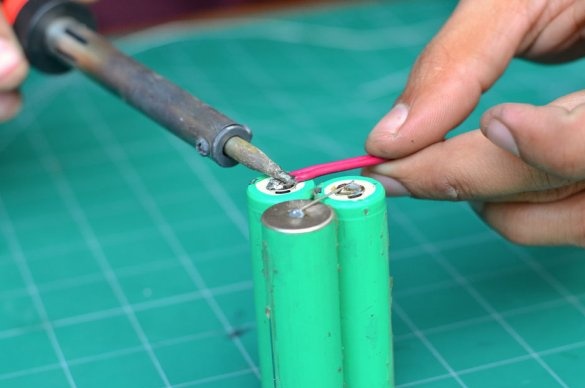

Step 5: Battery

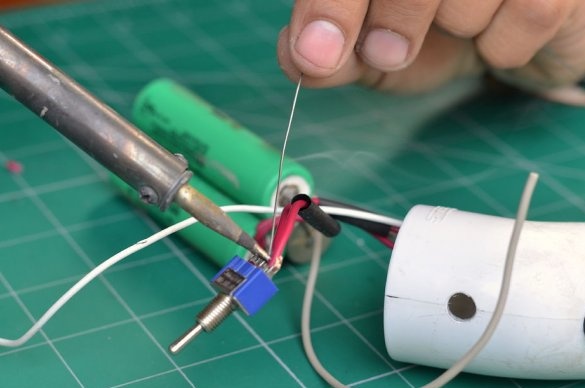

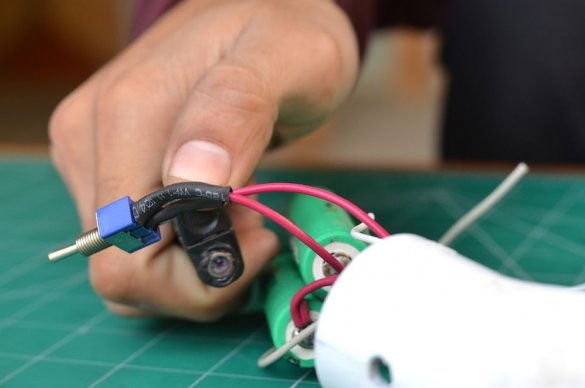

In order for this tool to work, it is required to assemble a battery using three lithium-ion cells with a capacity of 18650 mA / h. These batteries are from an old laptop battery. They kept the voltage above 3.7 V, so most likely they will work without interruption.

All three elements were soldered in series using a pair of wires connected to the positive and negative terminals of the battery. Of which one will then be connected directly to the charging connector, which is a 5 mm input connector. While the other pair is connected to the engine through a toggle switch, which will be used to turn the engine on and off.

In this design, there is no battery protection circuit that would prevent the battery from discharging below its minimum voltage. But this can be easily fixed by adding three TP-4056 modules. This will increase the reliability and performance of the battery.

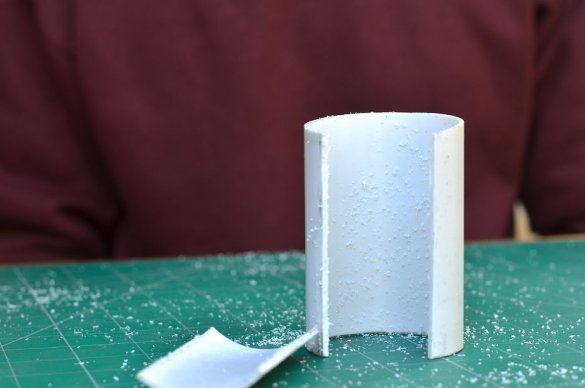

Step 6: Install the battery in the case

To close the installed battery, you need to make a case. For its manufacture, a 75 mm PVC pipe is used, which must be cut along so that it is ideally suited for the battery pack. The battery is first glued to the motor mount socket, and then the PVC pipe, which will be the body, is cut and glued. To maintain the desired shape, the cut pipe is fixed with two clamps. After the glue has dried, the clamps are removed and the glued place is ground so that the handle looks perfect and fits comfortably in the hand.

Step 7: Painting

To give this tool a neat appearance, it was decided to paint the case using matte black and yellow spray paint.

Step 8: Final Results

This mini brushless drill exceeded all expectations and showed itself very well in work. Although this type of engine is not designed for this kind of operation, it worked very well. Torque is large enough to grind metal. It can work with the largest 2.5 mm drill that can fit inside this adapter.

As for the battery, the power is enough for the tool to work long enough before the battery runs out.