Hello readers and friends.

The author of this homemade originally wanted to make a submachine gun from improvised materials. But as he did not try, he got a nozzle for a punch, for collecting dust during drilling holes. Itself device fastens on a puncher, in its hands (adaptation) it is not necessary to hold separately.

A hose from a vacuum cleaner is connected to the device, so when using this nozzle, when drilling a hole, there is no dust at all.

Also during drilling, the nozzle changes its length due to its design, which does not prevent the drill from plunging into the drill surface. Of course, this product has its drawbacks, and not everyone can approach it in view of its size, features of use and relatively complex design. But the idea itself is not bad. So I bring this homemade product to your court.

Tools and materials.

Manufacturing process.

Attention, all indicated dimensions are relative. If you intend to make such a device, it is worth considering the size and design of your rock drill, for which you will manufacture the fixture.

As the basis for this device, the author chose an old pipe gun for sealant, he will only need a body (an aluminum pipe with a diameter of about 50 mm). The author parses the gun and measures 300 mm on the tube of the body.

The excess part is cut off by the grinder, it cleans the seams with a file. The back cover on the gun pipe remains in place. In the center of the pipe, the author drills a hole with a diameter of about 30 mm. A PVC sewer pipe with a diameter of 40 mm will be connected to this hole. I will designate this pipe No. 1

The author cuts 300mm PVC pipes, smoothes the edges with a file. Cut a rectangular hole, retreating from the beginning of the tube 30-40mm. The length of the hole should reach the center of the tube. The width of the resulting hole is about 30-35mm. The master cuts the hole with a grinder, the edges should be filed to remove bumps. This tube will later be inserted into the aluminum tube. Note this pipe -№2

The author makes another piece of PVC pipe 300mm long, at one end makes semicircular cuts. The ears of the cutouts are heated under the flame of a burner and applied to an aluminum pipe to fix the shape of the ears. When the plastic tube is ready, the author places it in the hole in the end of the aluminum tube and temporarily fastens it using self-tapping screws. Pipe-3

Further, the author cuts a circle from plywood, processes the edges with a grinder.The diameter of the circle should be such that it stretches into the plastic pipe.

The author fastens the spring to the plywood circle on short screws with a wide hat, the spring should be 150 mm in length.

With the internal parts of this nozzle finished, now you need to make a mount. The author makes two holes in plywood with a diameter equal to the diameter of an aluminum tube, i.e. 50 mm, around each of the holes marks the future part in the form of a drop, cuts them out and polishes them. In the upper part of the drop, you need to drill a hole with a diameter equal to the diameter of the perforator depth limiter (a metal rod, usually attached to the handle of a perforator)

Now you can start assembling all the components. The author inserts a ring with a spring into the pipe -№2, from the side of the hole cut in the pipe, the spring directed from the pipe. As mentioned earlier, the circle must enter the pipe with a stretch.

Further, the author inserts the pipe No. 2 into the pipe No. 1 (aluminum), with a spring directed to the rear roof of the pipe No. 1. The drilled hole of the Pipe No. 1 and the cut hole of the Pipe No. 2 should coincide relative to each other.

To the pipe No. 1, the author fastens the pipe No. 3 to short self-tapping screws, so that they do not interfere with the course of the pipe No. 2

The author puts on drop-shaped fasteners on the edges of the resulting pistol; in the holes on the mounts, he sets the emphasis of the punch with a handle on it.

Now you need to make a dust collector.

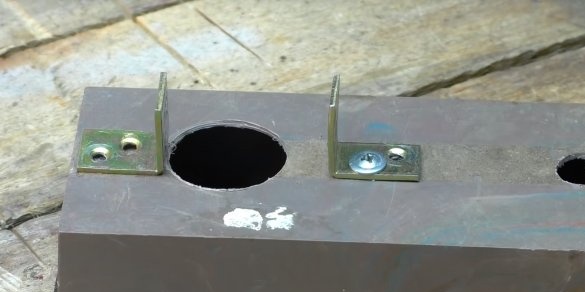

As a dust collector, the author will use a plastic box in which he makes holes and fasteners from the corners. Fastens the box to the pipe.

Fuhh .. On this device is completed, you can insert a hammer into the handle, connect the vacuum cleaner hose to the bottom tube and conduct tests.

After the tests, the author was convinced that there was no dust during drilling.

But as mentioned earlier, there are a number of disadvantages. The bulkiness of the design, the complexity of the design, the dust collector box covers a large area, thereby interfering with the review (if you need to compare by marks)

In general, we come across with criticism or approval))