In this article, YouTube author Dustin Penner will tell you

Materials

- 20 mm thick sheet plywood

- Threaded inserts

- Two-component epoxy resin

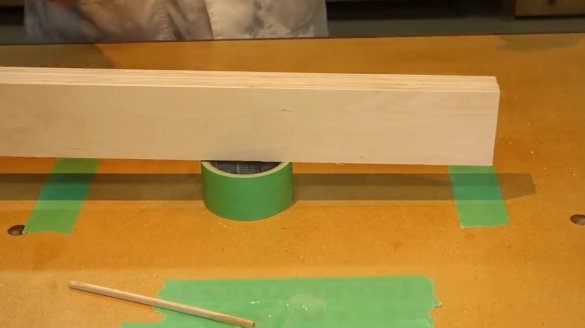

- masking tape

- Screws with thumb, M6 nuts

- PVA glue

- Furniture hinge

- Wood screws.

Instruments, used by the author.

- A circular saw

- Band-saw

- clamps

- Screwdriver

- Vise

- Drilling machine

- Forstner drills

- Square, pencil, tape measure, ruler

Manufacturing process.

First of all, the master cuts two long strips of plywood sheet, and marks two future holes on the ends. One on the edge, the second in the center.

Drills holes with a Forstner drill.

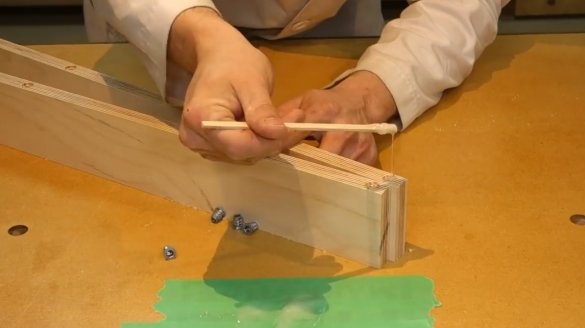

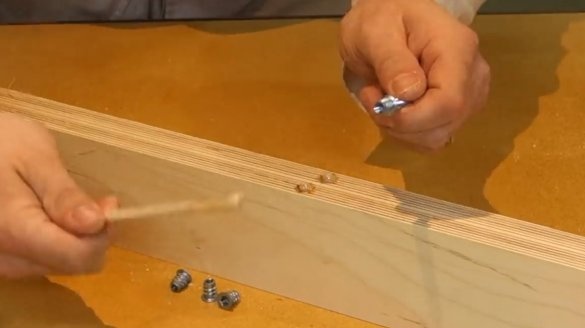

It mixes two-component epoxy resin, lubricates holes, and screw threaded inserts into them.

Turns over the workpiece, leaves the resin to polymerize.

Drills four holes in a small rectangular workpiece.

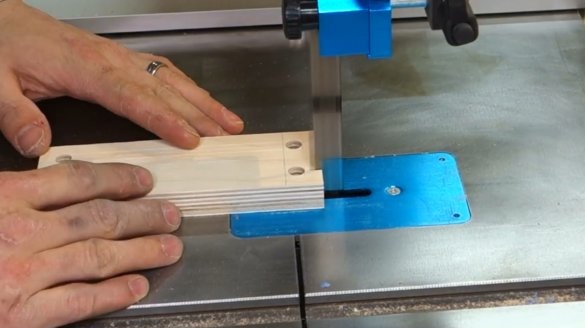

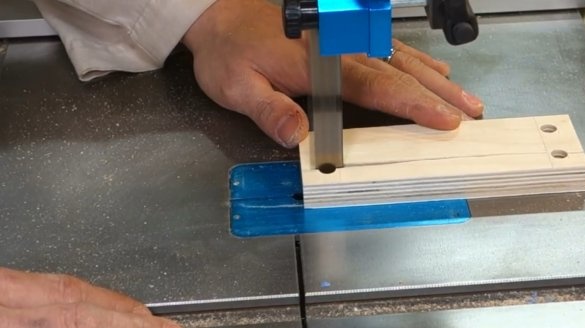

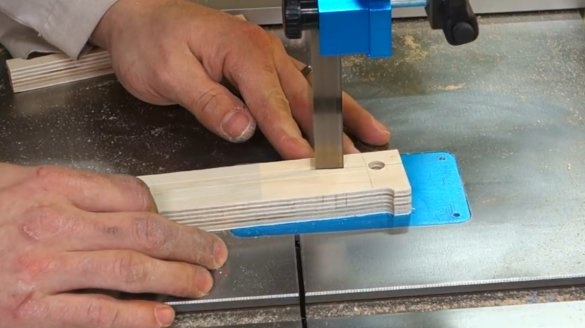

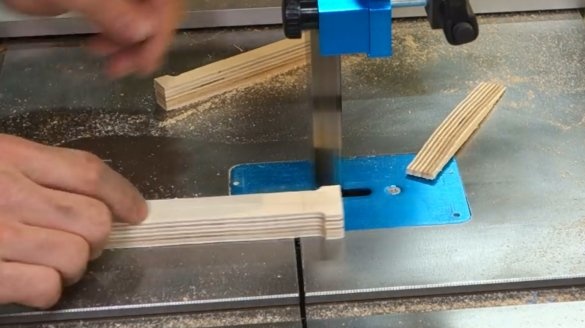

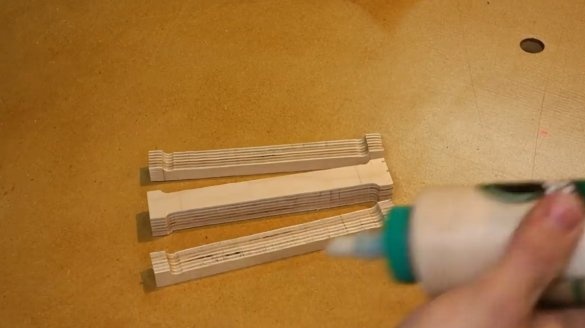

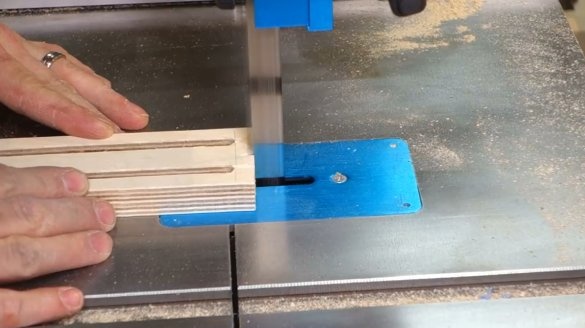

Then cuts the workpiece on a band saw in this way.

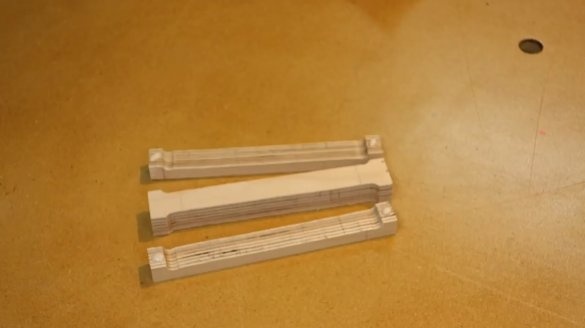

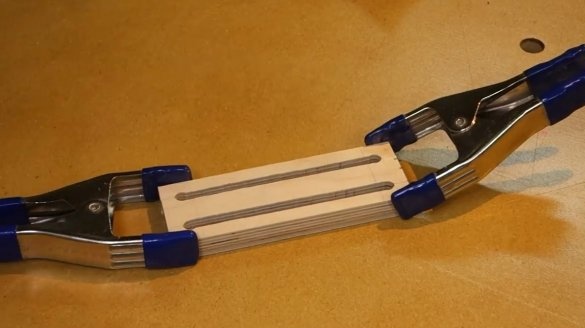

Glues workpieces, clamps with clamps.

Now an emphasis - a pusher sticks to one of the guides.

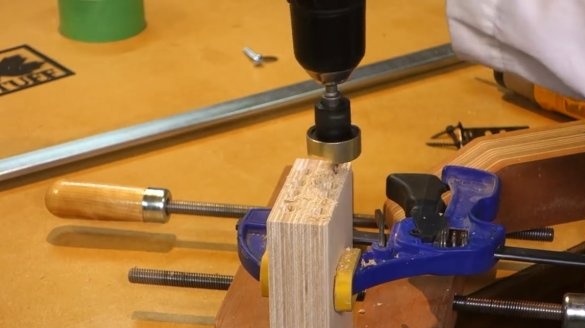

It fixes the guide in a vise, drills holes for screws.

Additionally fixes the stop with conventional wood screws.

Now clamps both guides in a vice, observing alignment. Drills holes, and fastens a furniture loop with self-tapping screws.

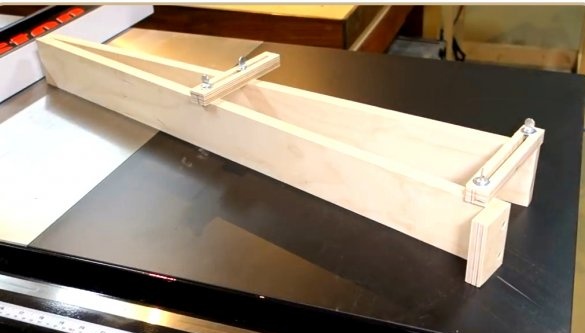

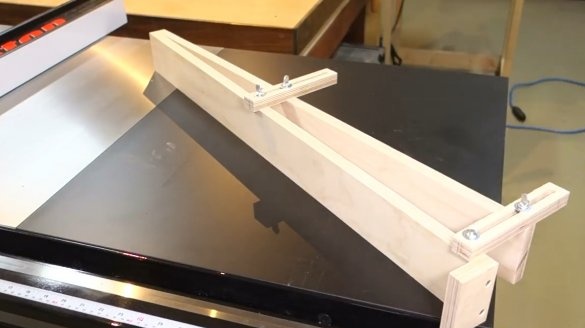

Main part fixtures ready.

Cuts the workpiece in two.

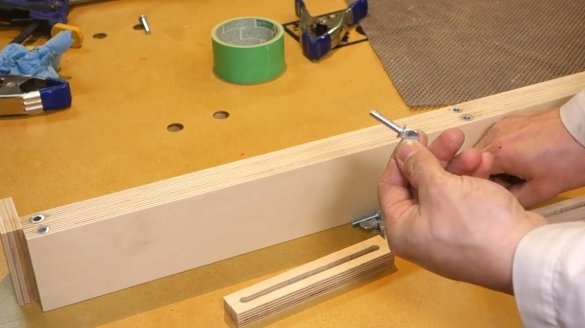

Screws the clamps with the thumbscrews to the guides through the washers.

That's all, the device is ready, and the angle is perfectly regulated.

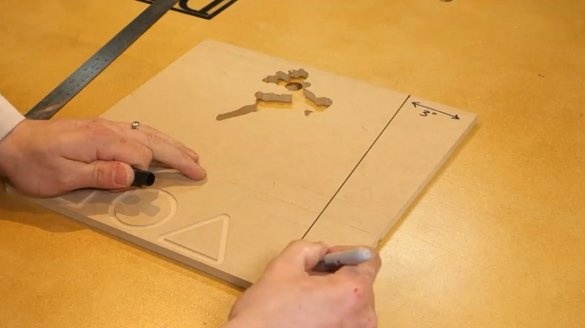

On an unnecessary piece, the MDF draws an oblique line. On the one hand 3, on the other 2 inches.

He sets the cutting line, puts an emphasis, clamps the clamps.

So quickly you can make an accurate incision at an angle.

This device can also be used as a conventional pusher.

Thanks to the author for a simple but useful tool for a circular saw!

All good mood, good luck, and interesting ideas!