Hello dear the inhabitants of our site!

Recently, I came across such, of course, not a problem, but a rather unpleasant thing. Earlier, when I did little enough to make or use the tool for its intended purpose, I still put up with it, but now it puzzled me. The thing is that when working, quite often I need small components, namely self-tapping screws, dowels, heads of various diameters and shapes, furniture bolts, etc. All this was laid out in jars, drawers and in other places. Therefore, now that I have often started to craft something, all this should be at hand, in one place and not occupy the workspace. Therefore, I decided to fix this thing and that's what I came up with. From work I dragged a lot of four-liter plastic canisters of rectangular shape. And from them I decided to make original containers for my little things.

So, let's begin.

For work, I needed tools such as:

- grinders with a disk,

- jigsaw (it can be replaced with any hacksaw),

- screwdriver,

- a drill for wood, self-tapping screws,

- roulette

- a simple pencil.

First of all, we prepare the container. We peel off all the stickers and use the grinder to saw off the upper part. I do not throw it away, since it is convenient to mix paints in it or to dilute a small amount of epoxy. It was her who I divorced in the cut-off part to firmly glue the rest of the lid to the neck of the canister. In short, the thing in the household is necessary.

Next, measure the canister on the sides. I take a small bar, somewhere 15 by 15 mm, and a thin board.

I used boards from vegetable boxes. I measure the distance I need, which is equal to the lateral length of the upper part of the cut-off canister and cut off the bars and planks along them.

Bars are used as runners. They are mounted on the outside of the canister. Planks go on strengthening and giving rigidity from the inside. I put a bar on the plank and drill holes for screws so as not to split the workpieces.

Next, I take a plank and a bar and put it on both sides of the canister, combining it through the holes. The wall of the container should be between these two blanks.

Self-tapping screws should come out a little from the workpieces, as they will be used later. Now measure the lateral distance between the two stiffnesses. We take the remaining bars and cut to size. They will be used as side struts. And strength will be added to the finished product.

We insert the whetstones between the side walls and fix them with screws. We do the same with the second side. Here is the result.

It is not necessary to twist the screws too much. Otherwise, even though the holes were pre-drilled in the blanks, they may burst. What happened to me. This is clearly visible in the top photo.

After that, we take small screws that do not exceed the thickness of the bar so that they do not come out from the back and twist them into the bar of the rear wall through the canister wall. I did not put a board under them, since the load there would not be big. All main weight will fall on the sidewalls. This was done more so that the plastic on the back of the canister would not “bulge out”.

Here is the result.

For testing in a finished box, I laid out my metal heads from the keys. Their total weight is slightly whiter than 2 kg. Holding the weight in her hand, the canister with the load did not bend, it was not pushed to the sides. Additional strength to the product also gives its handle.

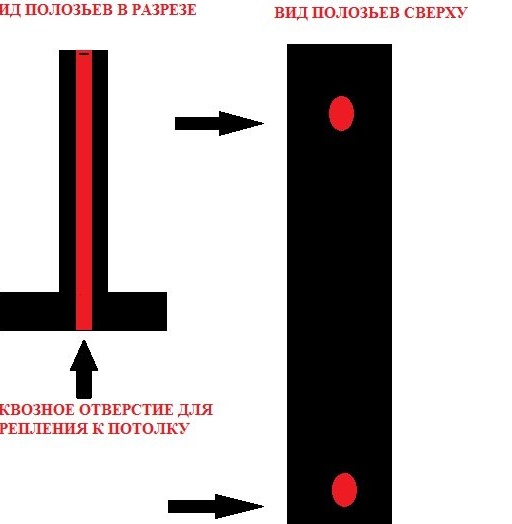

Now it remains to install them in their permanent place in the workshop. I will install them above the workbench on the ceiling. In terms of saving work space - the place is just perfect. My fasteners will be in the form of a T-shaped slide.

We drill through holes in the finished sled and through them we fasten to the ceiling using nails or self-tapping screws.

In the end, at the moment in my workshop there is such a battery of such convenient boxes. The problem of storing small things, but constantly required so that they were at hand, small things, was solved. Pulling them out is also quite easy, since the distance from the runners to the ceiling is designed so that the box moves freely along the guides and can be easily reached. The pen came in handy. it lies well in the hand and you can not be afraid that the whole box will fly out and fall, scattering small things throughout the workshop.

That's all. I hope my idea is useful to many in the matter of storing small parts. All the best and creative success!