In this article, the YouTube author of TheDacchio will tell you how to make a small multi-function grinder from a drill.

Moreover, this is not even a machine, but a holder for a drill, which will turn it into a small convenient tool without changing its design. And there are practically no financial costs.

Materials

- Profile pipe 25X25 mm

- Steel round timber with a diameter of 25 mm

- Stud 8 mm, bolt, nuts

- drill

- 48 mm diameter pipe

- Spray paint.

Instruments, used by the author.

- Band-saw

- Grinder, cutting-off and petal stripping discs

- Welding machine

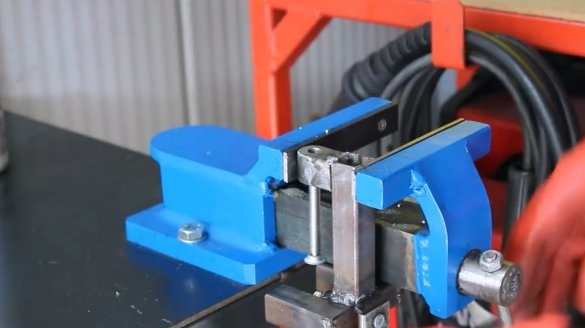

- Vise

- Drilling machine

- Step drill

- tap

- Caliper.

Manufacturing process.

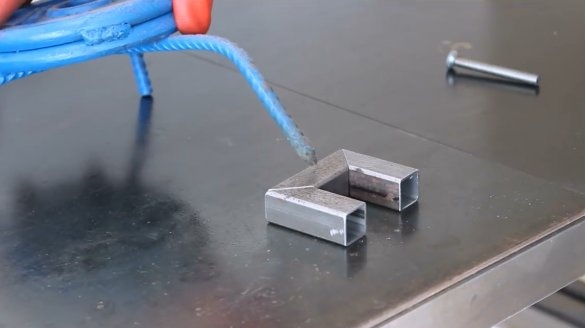

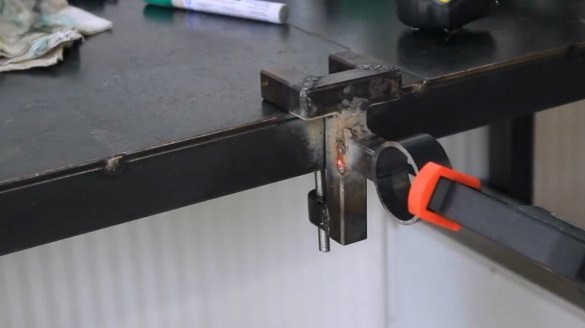

So, the first thing the master cuts the profile pipe into several blanks, two of the same only one bevel at 45 degrees, the third - two such bevels.

He collects such a U-shaped part, presses it to the table and boils the seams. This will be the top focus.

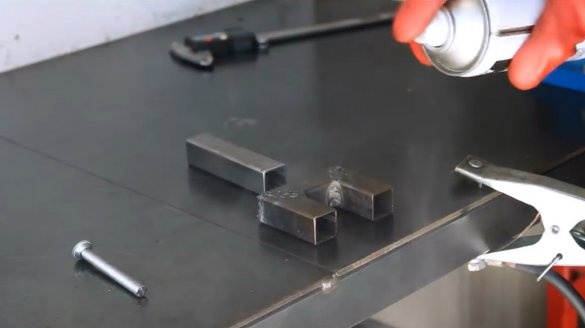

Then, having cut another workpiece from the profile pipe, it is welded to the first one, having previously been centered.

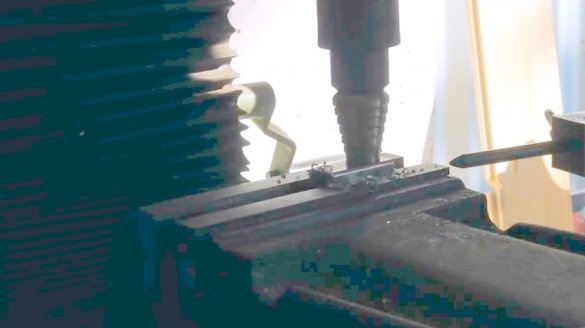

In another segment of the pipe, a through hole of 24 mm is drilled, almost touching its walls.

Cuts the center of the resulting hole.

Then he picks up a piece of steel round timber, and inserts it into the recess, fixing the workpieces in a vice. Welds them together.

Then, in the center of the round timber, drills a hole.

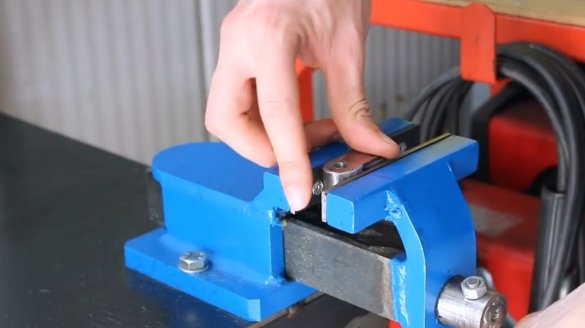

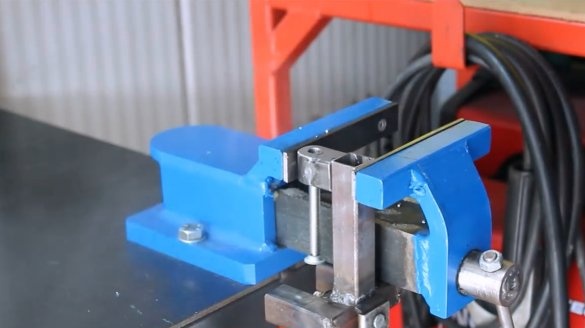

Clamps the workpiece in a vice, cuts the thread in the hole.

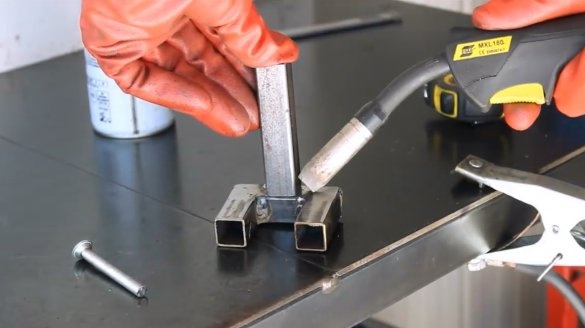

Having made the simplest clamping screw from the bolt and washer, it connects the workpieces to each other, welds.

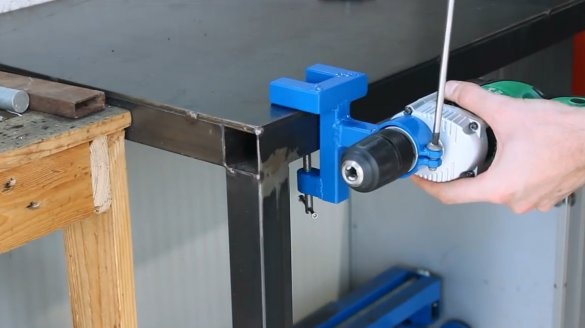

Measures the outer diameter of the neck of the drill, selects a pipe of suitable diameter. She should be free to dress on her.

It pokes a small depression in the profile pipe, suitable in shape to the segment of the round pipe. To do this, use a flap disc.

Welds all the workpieces together.

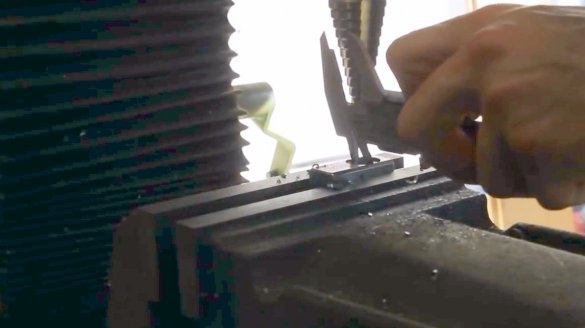

Now makes a longitudinal cut on the clip for the drill.

Welds a couple of nuts to it, having previously screwed them onto the bolt with a small allowance. Then cleans the seams and stains the product.

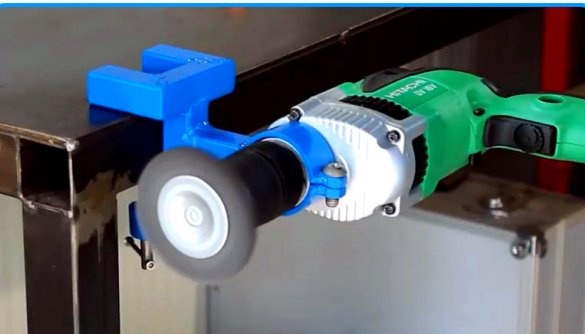

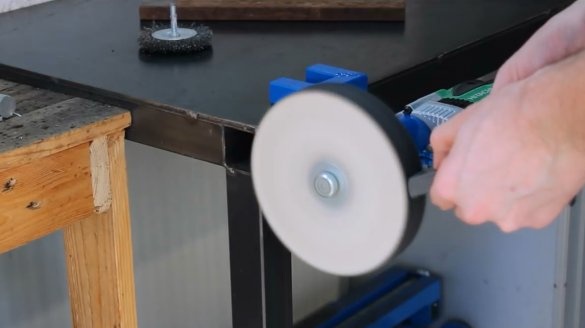

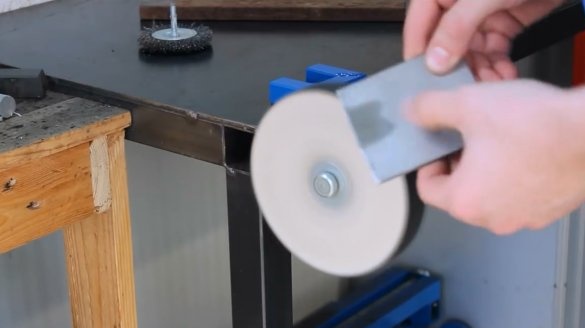

Locks finished device on a workbench, clamps a drill in it.

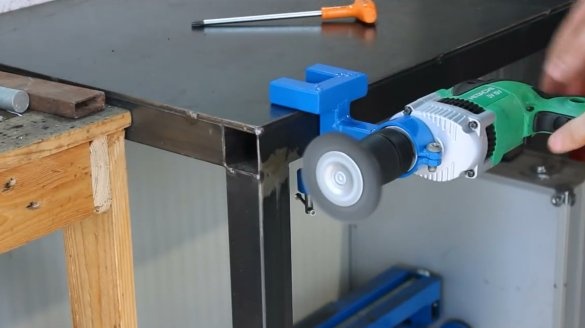

Now he puts the nozzle, and gets a simple cleaning stanochka.

And with such a nozzle, a polishing machine is obtained. There are a great many nozzles - there will be fantasies where to roam, because hands are now free!

Thanks to the author for a simple but useful tool for the workshop!

All good mood, good luck, and interesting ideas!