Greetings to all lovers of crafting something do it yourself.

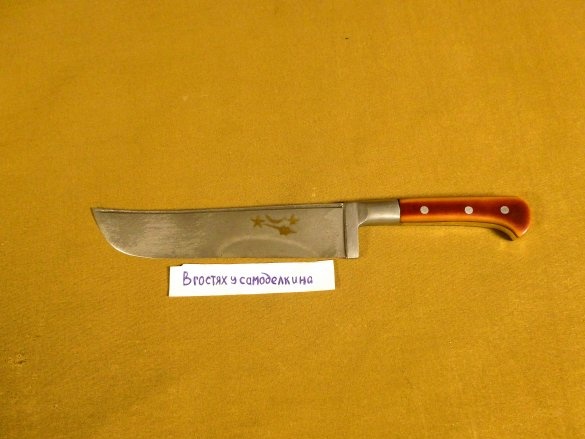

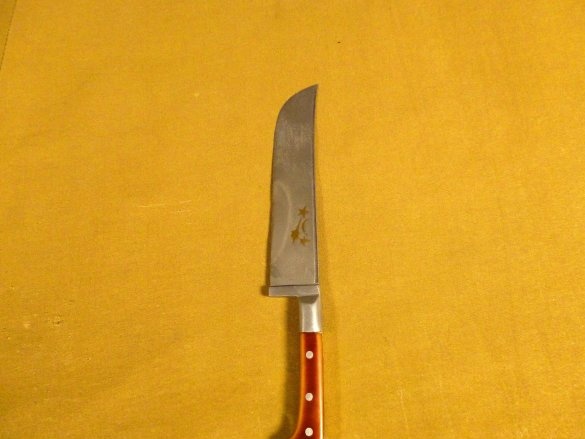

Today we’ll try to reanimate a pusher knife, who has done something wrong with his master and was severely beaten.

There is an assumption that they wanted to grind it using the delay method to the cold, but apart from a damaged blade, a broken gulband and cracked pads, nothing came of it.

Tools needed and fixtures.

1. Electric drill

2. Sharpening machine

3. Various vise

4. The hammer

5. Industrial hair dryer

6. Electric stove

7. The expansion bolt shield from the construction gun

8. Bicycle spoke

9. Electric kettle

10. Screwdriver

11. Pliers

12. Side cutters

13. File

14. Needle files.

Materials and consumables needed.

1. Textolite 0.8 mm thick

2. Textolite 2 mm thick

3. Aluminum rivets

4. Tin

5. Wooden block

6. Asbestos

7. Pasta GOI

8. Citric acid

9. 1.5 liter can

10. Canvas from a hacksaw for metal

11. Sandpaper.

To begin, we will analyze the handle of the knife. To do this, knock out the old aluminum rivets. You can tear them off with a dowel from a construction gun and finally knock out a bicycle spoke.

Now remove the broken gulband with a hammer, screwdriver and pliers.

When disassembling, it turned out that the inner inserts in the handle are made of cardboard, we will replace them with textolite inserts. But first, try to align the blade and bring it into proper shape.

With light hammer blows we level the blade. After the last sharpening, it turned out to be very difficult.

We clean with sandpaper.

After polishing on a felt circle, using GOI paste.

Now it’s the turn of the gulband.

The wooden block was split in half and a drill was drilled in it an approximate form of the future gulband, not forgetting the gate and the air vent.

Holes, which should be blind and turned through, were covered with wet asbestos

and dried with an industrial hairdryer.

We heat the tin on an electric stove and pour it into a mold.

When the workpiece cools down, disassemble the form

and remove the excess with side cutters.

Clamp the blade in a vice and give shape to the guilband, first with a file, then with files.

The handle will be made of PCB.

For internal inserts we use textolite 0.8 mm thick. We mark on old cardboard inserts

and cut the blade from a hacksaw for metal, for convenience, the blade can be clamped in a manual vice.

We attach the final form to the inserts on the grinding machine.

We drill holes for rivets.

Pads are made of PCB with a thickness of 2 mm.

Mark on the handle of the knife and cut out with a cloth.

We drill holes for rivets with an installed insert. From the outside, we drill holes with a drill of a larger diameter, for better fixing of rivets.

Putting all the handle parts together

and rivet the rivets.

We give the rough shape of the handle on the grinding machine.

We give the final form with a file, files and sandpaper.

We polish the handle on the felt circle.

The knife is ready, it remains only to protect it from corrosion, for this we carry out oxidation.

In 1.5 liters. hot water dissolve 20 gr. citric acid.

Degrease the blade and lower it into acid.

We are waiting for the reaction to end. We periodically take out the knife and gently erase the resulting coating. After the end of oxidation, we wash the blade and lubricate it with oil to completely stop the reaction.

Unfortunately, they could not completely get rid of the traces of the barbaric treatment, but the patient is more likely alive than dead.

All good and good luck in work.

You can watch a video about knife repair here.